Electric heating type superconductor lustring roller

A technology of ironing rollers and superconductors, which is applied in textiles, papermaking, and fabric surface trimming, etc. It can solve the problems of high energy consumption of electrically heated ironing rollers, large temperature differences on the roller surface, and high production costs, and achieve good energy-saving effects and heat conduction High efficiency and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

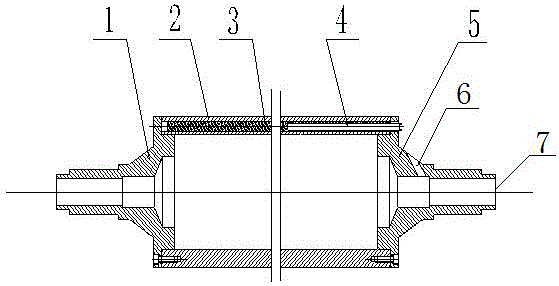

[0016] Such as figure 1 As shown, an electrothermal superconductor ironing roller includes a left shaft head 1, a ironing roller shell 2, a superconducting material 3, an electric heating tube 4 and a right shaft head 5; the left shaft head 1 and the right shaft head 5 One end of the ironing roller shell 2 is in the shape of a boss, and the other end of the left shaft head 1 and the right shaft head 5 is in the shape of a cone; The table is fixedly connected by bolts to form the main body of the ironing roller; the radial direction of the ironing roller shell 2 is uniformly provided with 15 channels of Φ40, and after installing an electric heating tube 4 in each channel, add a superconducting material 3 in the remaining space, Then the channel opening is sealed; the radial direction of the right shaft head 5 is evenly provided with 15 through holes of Φ40, and the through holes of each right shaft head 5 correspond to the channels of the ironing roller shell 2 one by one, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com