Electromagnetic induction ironing roller

An electromagnetic induction and ironing roller technology, which is applied in the direction of textiles, papermaking, and fabric surface trimming, can solve the problems of oil heating ironing roller development constraints, high energy consumption, and high production costs, so as to save high-power electricity, rollers, etc. The surface temperature is constant and the effect of improving the quality of scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

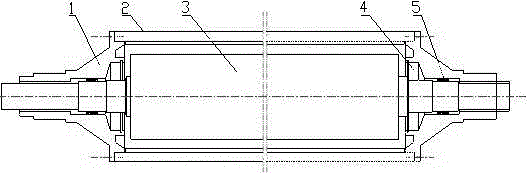

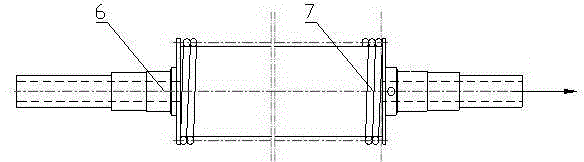

[0010] Such as figure 1 with figure 2 As shown, the electromagnetic induction scalping roller designed in the present invention includes a scalping roller shell 2, two skeleton oil seals 5, two shaft heads 1, two bearings 4, two flanges, a high temperature coil 7, and a coil core 3. And the rotating core shaft 6 passing through the coil rotating core 3; wherein the length of the rotating core core shaft 6 is greater than the length of the coil rotating core 3, and the coil rotating core 3 is located at the center of the rotating core core shaft 6; The length of the roller shell 2 is adapted to the length of the coil rotor core 3. The scalping roller shell 2 is sleeved outside the coil rotor core 3; one end of each shaft head 1 is in the shape of a boss. The two ends are respectively connected with the boss portion of each shaft head 1, and the two ends of the rotating core mandrel 6 respectively pass through the shaft head 1 located at the two ends of the scalping roller shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com