Method for producing double-smooth surface belt by utilizing cattle vegetable tanned harness leather

A double-smooth, vegetable tanning technology, applied in leather manufacturing, leather surface treatment, leather surface mechanical treatment, etc., to achieve the effect of adjustable length, increased strength, and clean and bright sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 A method of making double-smooth leather belts from cattle vegetable tanned leather

[0061] A method for making double-smooth leather belts by using yellow cattle vegetable tanned leather, according to the following steps:

[0062] ⑴ Cutting strips

[0063] Cut out 1500×33mm belt strips on the whole piece of yellow cattle vegetable tanned leather, and get A;

[0064] ⑵ split layer

[0065] Pass A through a splitter, split to 2.2mm, and get B;

[0066] ⑶ grinding

[0067] Use 600-grit sandpaper to polish the rough surface and two sides of B until it is smooth and flat, and get C;

[0068] ⑷ scraping and leveling

[0069] Apply the mending ointment to the hairy surface and both sides of C, and spread it evenly until the hairy surface of C covers the small hairs, then put it in a ventilated place, and let it dry naturally to obtain D;

[0070] ⑸Secondary grinding

[0071] Use 800-grit sandpaper to lightly polish the position where the repair cream was ap...

Embodiment 2-6

[0098] Embodiment 2-6 Utilize the method for making double-smooth leather belts of yellow cattle vegetable tanning

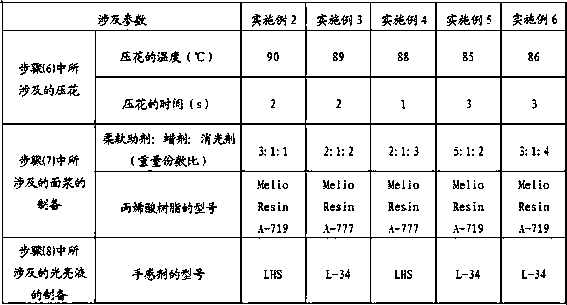

[0099] Embodiments 2-6 are respectively a method for making double-smooth leather belts by using yellow cattle vegetable tanned leather. The manufacturing process is the same as that of Embodiment 1. The number of times of spraying the flour paste in step (7) is 3 times. The difference is only in the control The parameters are different, as shown in Table 1:

[0100] Table 1 Relevant parameters involved in the method of making double-smooth belts from cattle vegetable tanned leather

[0101]

[0102] The production process of Examples 2-6 is simple, and the belt provided is smooth and delicate, with good air permeability, clear and natural grain pattern, anisotropic creases, three-dimensional effect, clean and bright surfaces on both sides, smooth appearance, and wear-resistant coating. High strength, adjustable strap length.

Embodiment 7

[0103] Example 7 The strength and color fastness to rubbing of a double-smooth belt made of bovine vegetable tanned leather

[0104] Embodiment 7 has carried out strength and color fastness to rubbing test to the belt provided in embodiment 1-6, and concrete result is as follows:

[0105] ⑴Strength test

[0106] Tensile strength≥22N / mm 2 , compressive strength ≥ 190MPa.

[0107] ⑵ Color rubbing fastness test

[0108] Dry rubbing ≥ 4 (level), wet rubbing ≥ 3 (level).

[0109] The evaluation standard for domestic belts is tensile strength ≥ 15N / mm 2 , when the compressive strength is ≥130 MPa, the strength of the belt is qualified; when the dry rubbing is ≥3 (grade), and the wet rubbing is ≥2 (grade), the color rubbing fastness of the belt is qualified. Tensile strength≥19 N / mm 2 , When the compressive strength is ≥150MPa, the belt has high strength; when the dry rubbing is ≥4 (grade), and the wet rubbing is ≥3 (grade), the color rubbing fastness of the belt is high.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com