Hydraulic transmission and control system for press machine

A technology of hydraulic transmission and control system, which is applied in the directions of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., and can solve the problems of poor reliability, high oil temperature and noise, and high maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

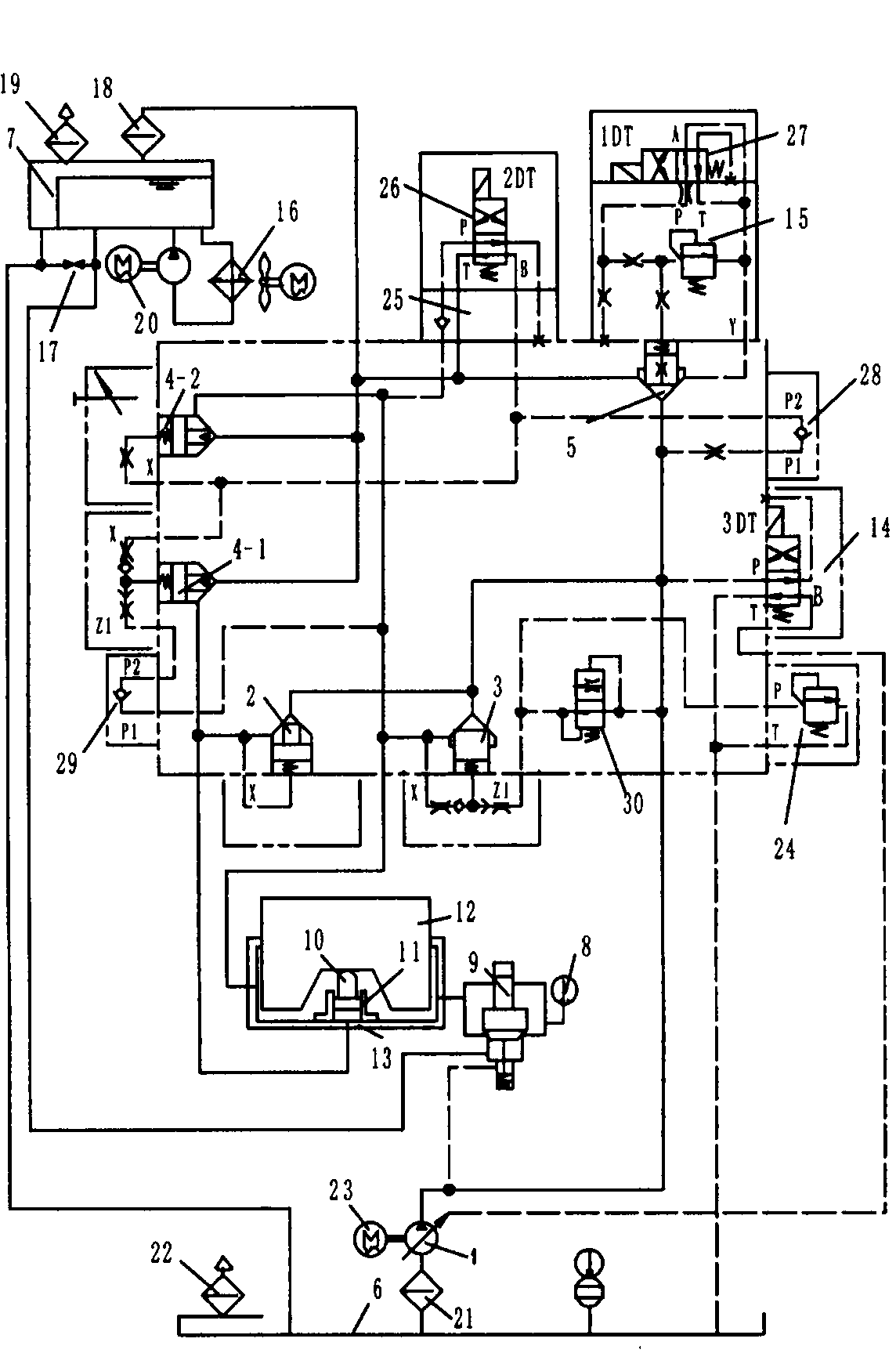

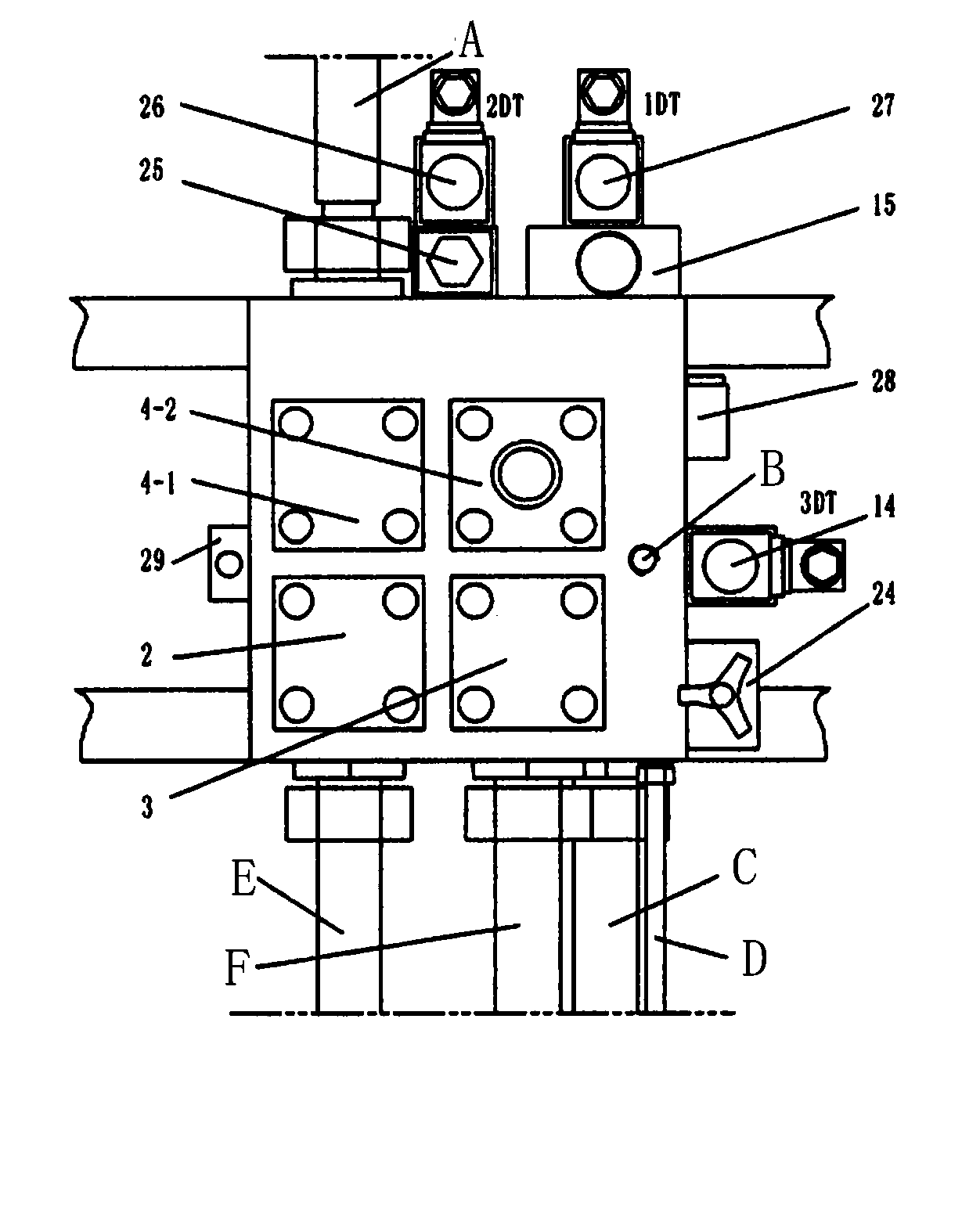

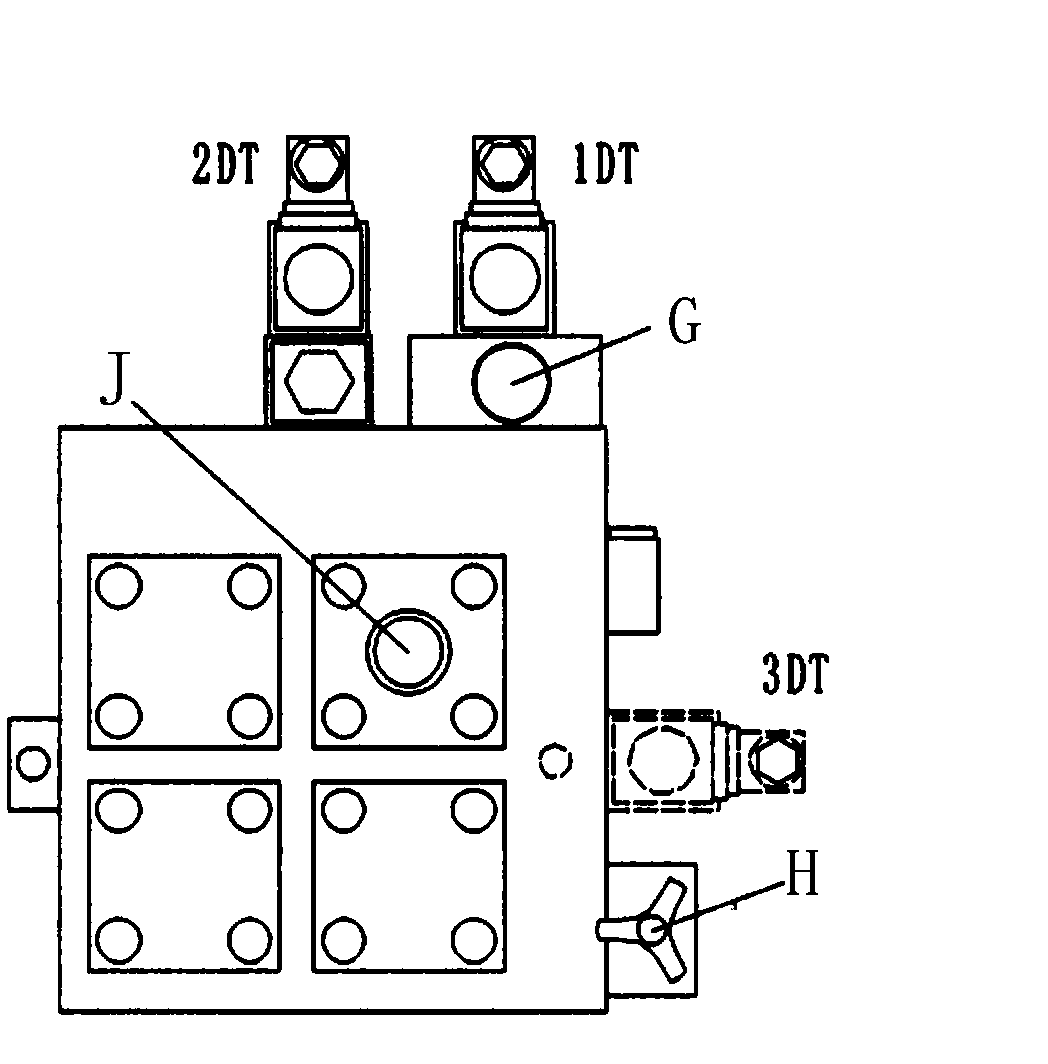

[0027] Detailed ways: The present invention will be further described below in conjunction with accompanying drawing:

[0028] The present invention provides a hydraulic transmission and control system for a press, the system includes a combined valve block under centralized control and a small hydraulic cylinder 11 connected thereto, a large hydraulic cylinder 13, a main oil tank 6 and an auxiliary oil tank 7; A first cartridge valve 2, a second cartridge valve 3, a third cartridge valve 4-1, a fourth cartridge valve 4-2, a fifth cartridge valve 5, and a flow limiting valve 30 are installed on the combined valve block. , electromagnetic reversing valve 14, pilot relief valve 24, first electromagnetic reversing valve 27, second electromagnetic reversing valve 26 and one-way valve 28; the combined valve block of centralized control is provided with a connecting channel; the main oil tank 6 is connected The hydraulic pump 1 supplies oil to the hydraulic pump 1; the hydraulic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com