Automatic embossing machine

An embossing machine and automatic technology, applied in the direction of mechanical processing/deformation, leather surface mechanical treatment, small raw leather/big raw leather/leather/fur mechanical treatment, etc., can solve the problems of inability to form a three-dimensional aesthetic feeling, insufficient pressure, etc., and achieve The effect of stable and reliable volume, improved quality, improved speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

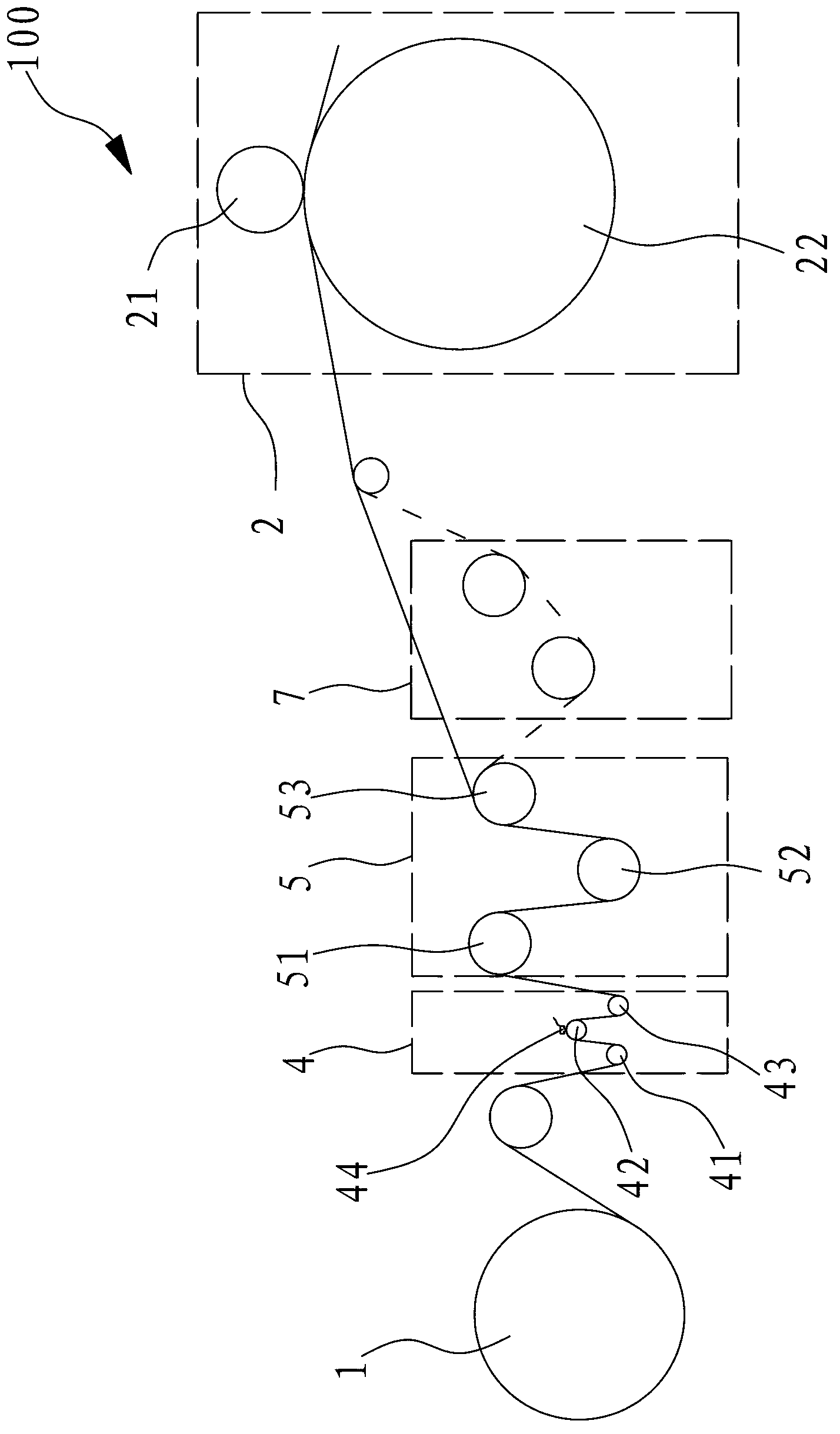

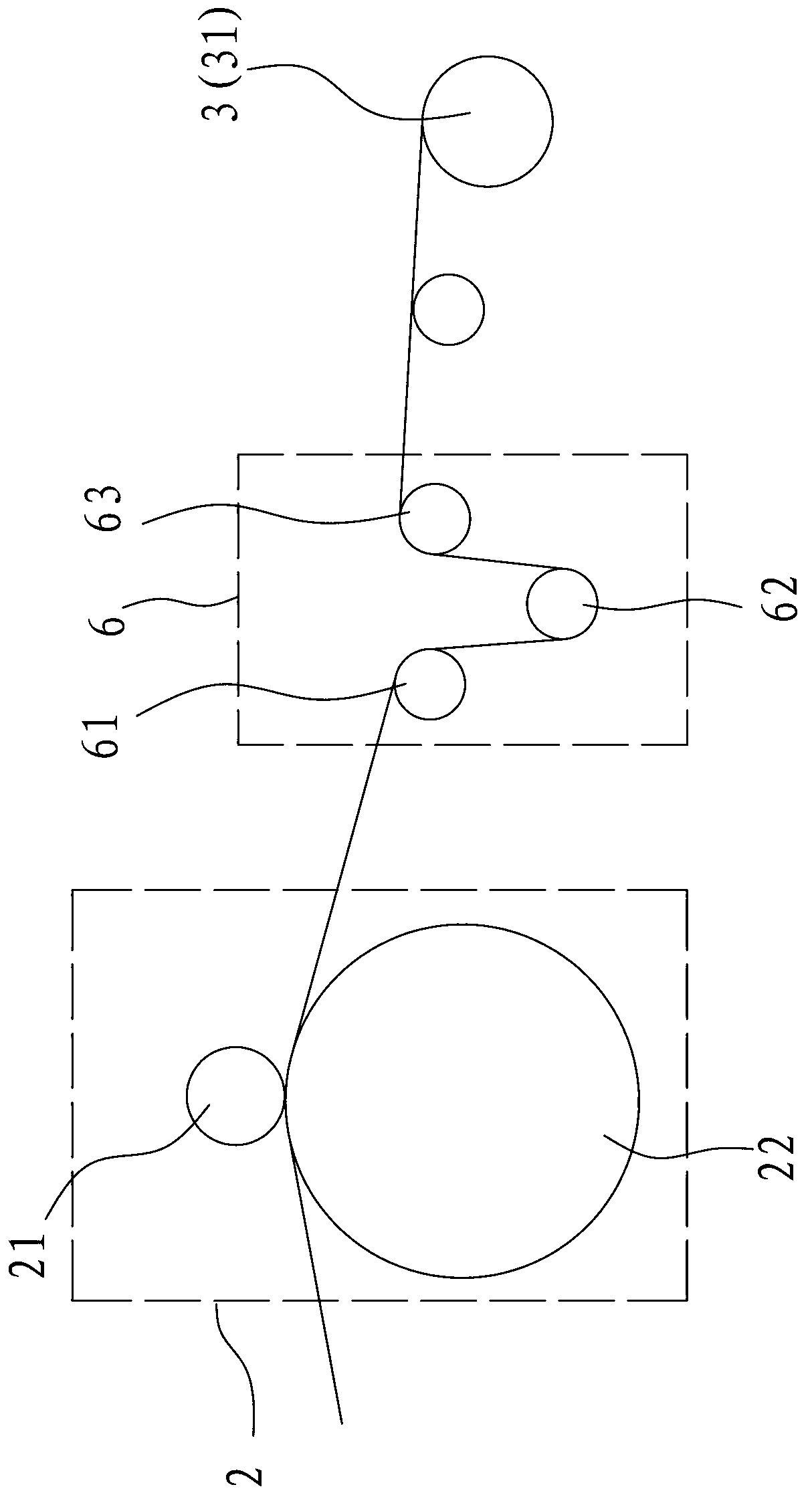

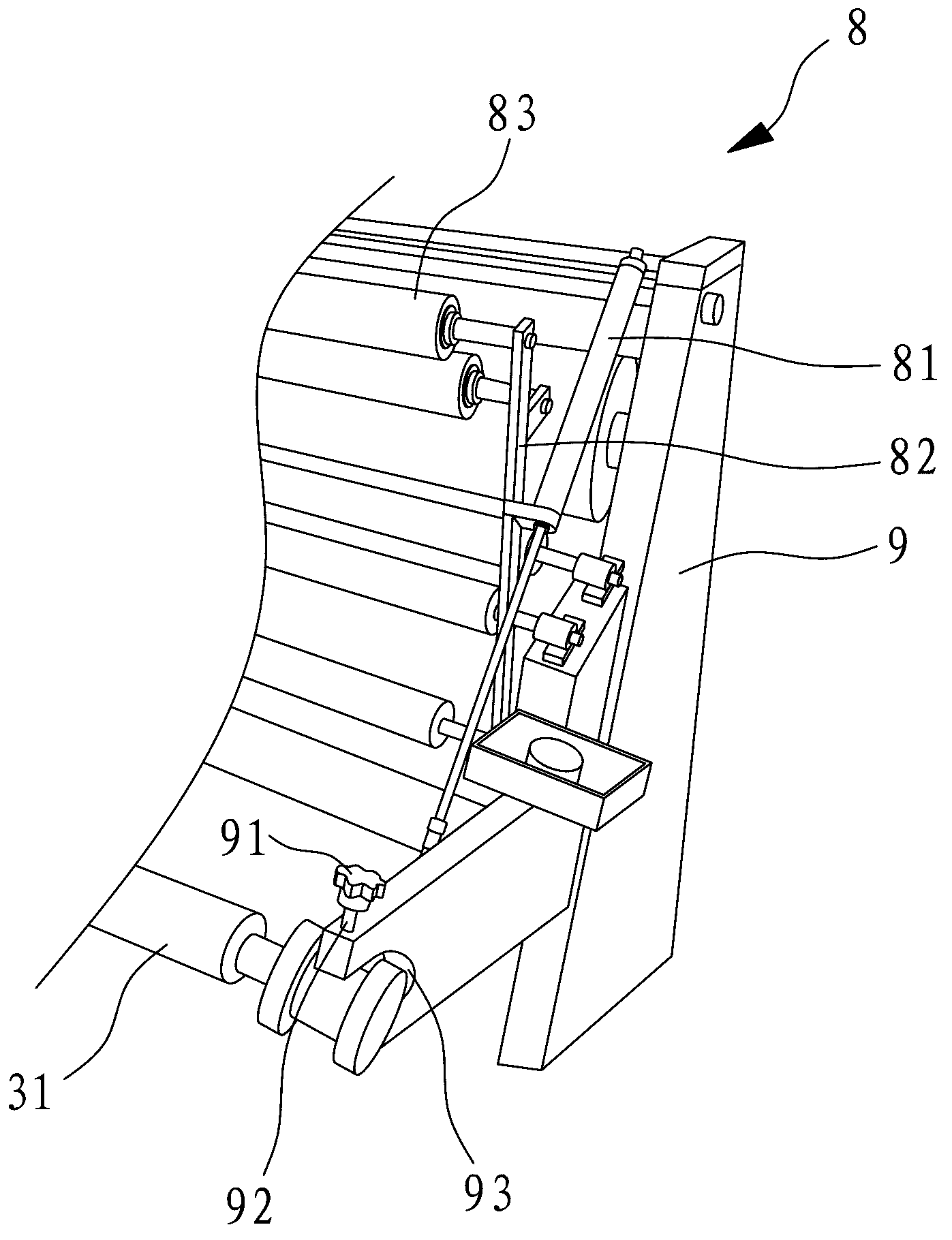

[0045] like figure 1 and figure 2 As shown, an automatic embossing machine 100 related to the present invention at least includes a feeding device 1, an embossing device 2 and a receiving device 3, and the feeding device 1, the embossing device 2 and the receiving device 3 follow the material The running direction is arranged sequentially. The feeding device 1 is to convey the roll-shaped material outward at a certain speed. The embossing device 2 has a patterned roller 21, a hard roller 22 and a hydraulic mechanism (not shown in the figure). The patterned roller 21 is located above the hard roller 22 and is tangent to the hard roller 22. The hydraulic mechanism is connected to the patterned roller 21 and can change the force between the patterned roller 21 and the hard roller 22. When the hard roller 22 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com