Production method for split-layer oil wax waterproof leather

A production method and technology of split leather, applied in leather softening, leather surface treatment, leather surface mechanical treatment, etc., can solve the problems of poor waterproof effect of leather materials, hard to disappear, poor wet rub resistance, etc., and achieve excellent water resistance and wet rub resistance, strong oily waxy feeling and color difference, and the effect of enhancing the antique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

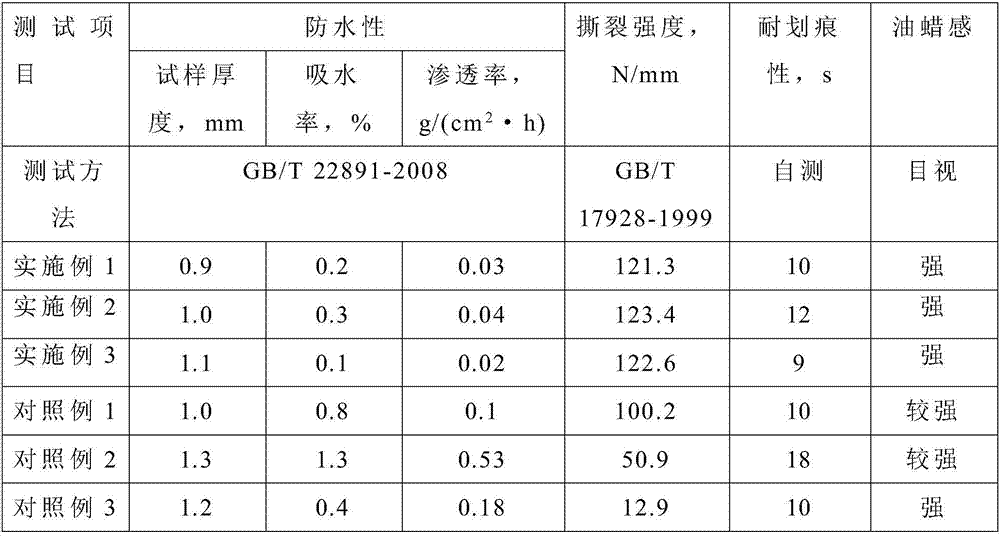

Examples

Embodiment 1

[0027] The production method of two-layer oil wax waterproof leather comprises the steps:

[0028] Take the cow split hide and dry it;

[0029] Grinding: Take the dried two-layer leather, use 180# and 220# to grind the bottom surface of the leather, use 280# and 180 # Grind the surface of the skin with gravel, and sweep the skin ash after grinding;

[0030] One-time softening: put the leather base after grinding into the softening drum and soften for 60 minutes;

[0031] Spraying: In parts by mass, add 30 parts of acrylic resin MELIO RESIN A-776 to 180 parts of water, raise the temperature to 55°C, stir evenly, spray the acrylic resin slurry on the surface of the skin that has been softened once above, and spray When the acrylic resin slurry consumption is 25 grams per square meter of skin blank.

[0032] Roller oil wax: heat the oil wax until it melts, heat the roller coater to 90°C, pour the oil wax into the roller coater, set the rolling speed and blanket speed ratio to ...

Embodiment 2

[0037] The production method of two-layer oil wax waterproof leather comprises the steps:

[0038] Take the cow split hide and dry it;

[0039] Grinding: Take the dried two-layer leather, use 180# and 220# to grind the bottom surface of the leather, use 280# and 180 # Grind the surface of the skin with gravel, and sweep the skin ash after grinding;

[0040] One-time softening: put the leather base after grinding into the softening drum and soften for 55 minutes;

[0041] Spraying: In parts by mass, add 20 parts of acrylic resin MELIO RESIN A-776 to 150 parts of water, raise the temperature to 50°C, stir evenly, spray the acrylic resin slurry on the surface of the skin that has been softened once above, and spray When the acrylic resin slurry consumption is 20 grams per square meter of skin blank.

[0042] Roller oil wax: heat the oil wax until it melts, heat the roller coater to 85°C, pour the oil wax into the roller coater, set the rolling speed and blanket speed ratio to ...

Embodiment 3

[0047] The production method of two-layer oil wax waterproof leather comprises the steps:

[0048] Take the cow split hide and dry it;

[0049] Grinding: Take the dried two-layer leather, use 180# and 220# to grind the bottom surface of the leather, use 280# and 180 # Grind the surface of the skin with gravel, and sweep the skin ash after grinding;

[0050] One-time softening: put the leather base after grinding into the softening drum and soften for 50 minutes;

[0051] Spraying: In parts by mass, add 40 parts of acrylic resin MELIO RESIN A-776 to 200 parts of water, raise the temperature to 60°C, stir evenly, spray the acrylic resin slurry on the surface of the skin that has been softened once above, and spray When the acrylic resin slurry consumption is 30 grams per square meter of skin blank.

[0052]Roller oil wax: heat the oil wax until it melts, heat the roller coater to 95°C, pour the oil wax into the roller coater, set the rolling speed and blanket speed ratio to 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com