Leather printing

A leather and printing technology, applied in the field of computer programs and computer systems, can solve problems such as blurring, uneven color/pattern, and difficulty in leather printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be understood that, except in the appended claims, the following description is intended to refer to specific embodiments of selected structures in the drawings, and is not intended to define or limit the present disclosure.

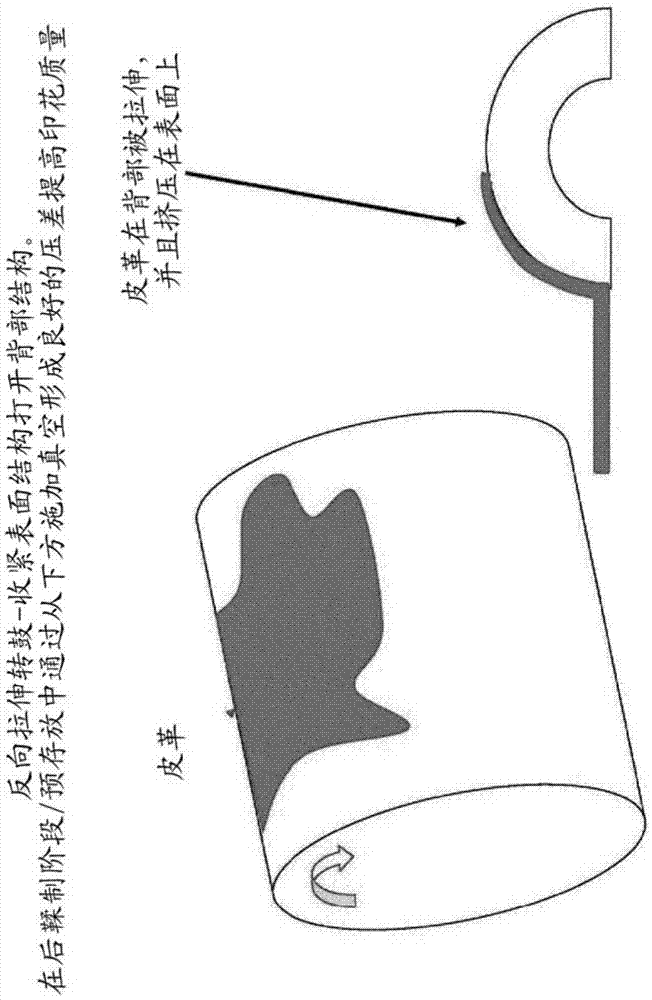

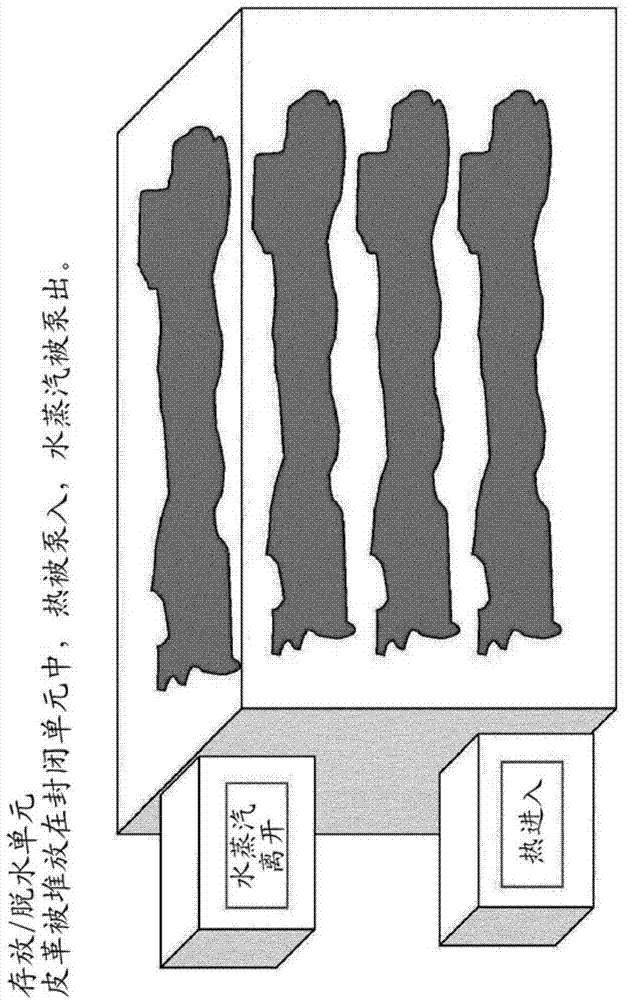

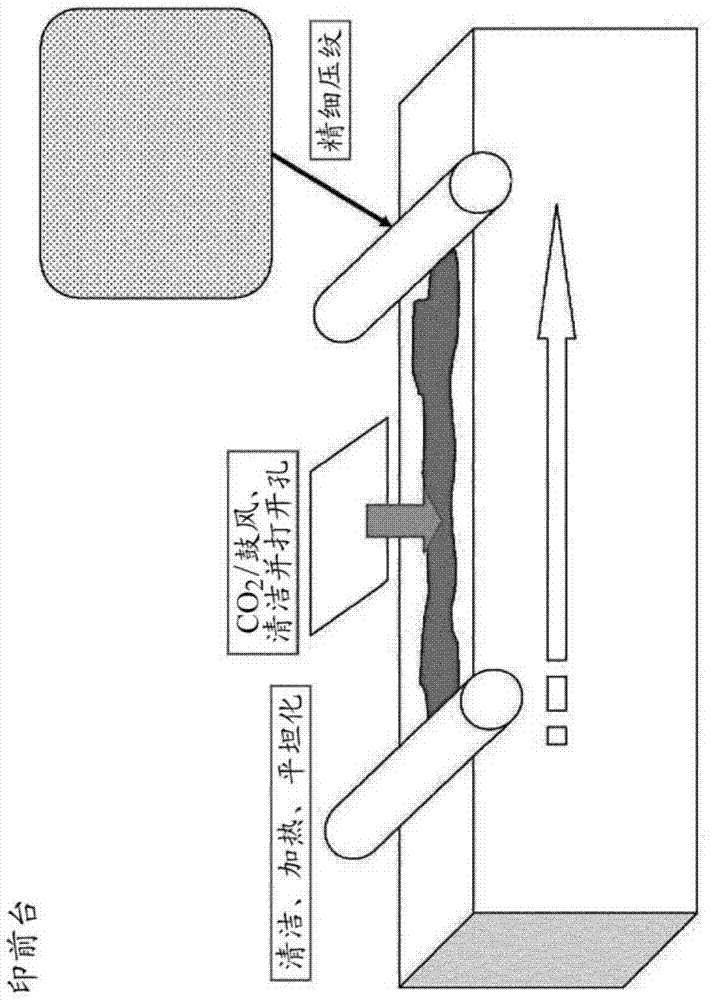

[0038] The present invention provides an apparatus for leather printing. The apparatus may include an ink receptor applicator configured to apply an ink receptor base coat directly to the surface of the leather; an ink applicator configured to apply ink directly to the base coat and / or the surface of the leather additive applicator arranged to apply additives to the surface of a base coat, ink and / or leather; an autoclave arranged to heat a surface to a predetermined temperature or a temperature within a predetermined temperature range, additive The ink, which is placed in direct contact on the surface, softens and coats the leather so that the applied receptor and additive covered ink penetrates the leather, where the additive forms a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com