Leather grinding machine

A dermabrasion machine and leather technology, applied in the field of machinery, can solve the problems of unreachable leather samples, low research and development efficiency, waste of research and development personnel time, etc., and achieve the effect of simple mechanical structure, dust pollution prevention and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

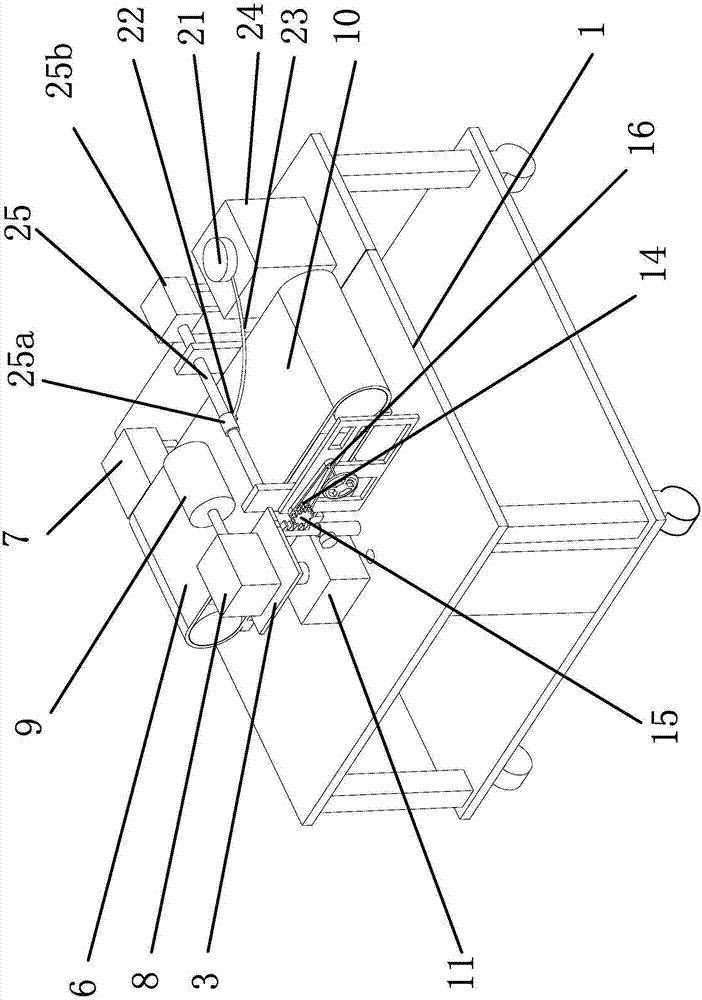

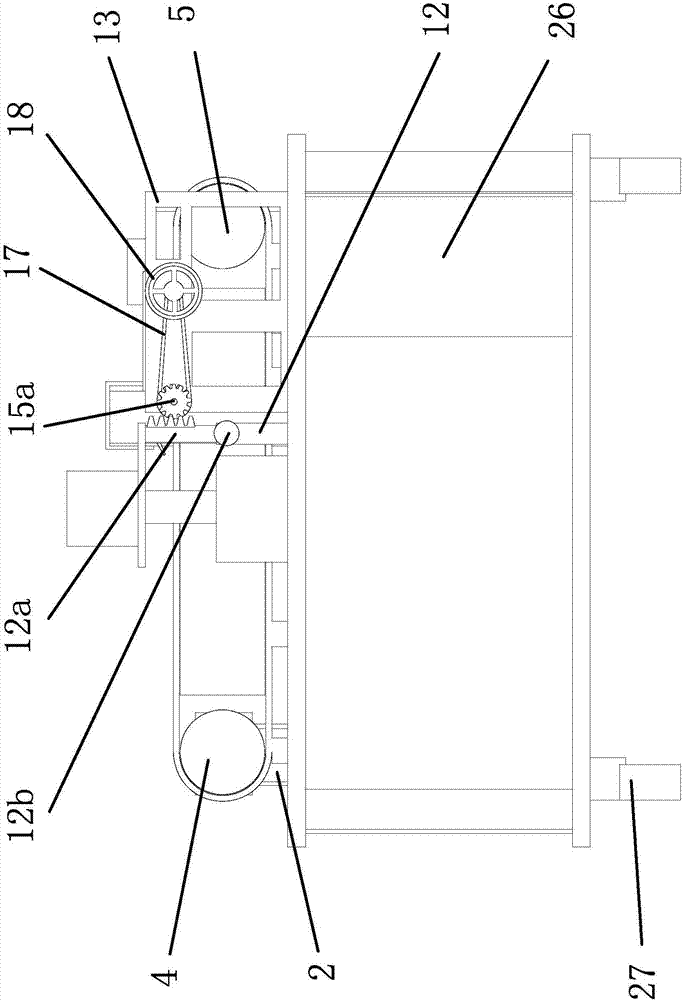

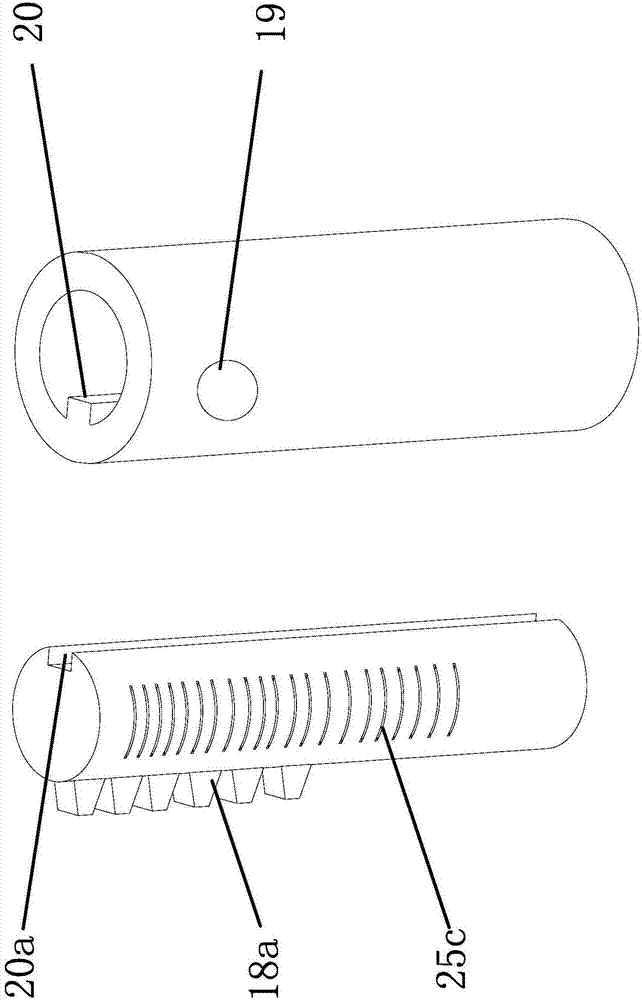

[0025] figure 1 , figure 2 with image 3 Shown, a kind of leather smoothing machine comprises base 1, is arranged on base 1 fixed table 2 and the movable table 3 on base 1, is characterized in that, fixed table 2 is provided with first roller 4 and second The roller 5, the first roller 4 and the second roller 5 are arranged in parallel, and the first roller 4 and the second roller 5 are all fixed on the fixed table 2 by rotating in the circumferential direction and fixed in the axial direction. A conveyor belt 6 is set between the first roller 4 and the second roller 5, and the first roller 4 is driven by the first motor 7; the movable platform 3 is located on one side of the fixed platform 2, and a push movable platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com