Acid reaction resistant chinlon fixer and application thereof

A color-fixing agent, reactive technology, applied in dyeing, textile and papermaking, etc., can solve the problems of defective products, color-fixing agent spots, acid insufficiency, etc., to prevent staining, improve wet fastness, working fluid stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

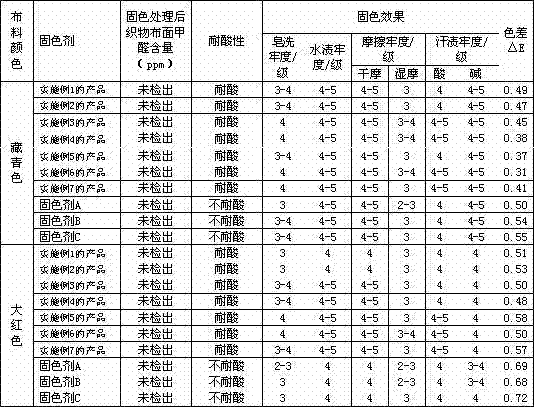

Examples

Embodiment 1

[0022] Add 100g of bisphenol A, 58g of phenolsulfonic acid, 42g of sulfonated bisphenol S, 260g of water, 0.5g of boric acid into a four-neck flask equipped with a condensing reflux tube, a thermometer, a dropping funnel and a stirrer, and slowly add 30% liquid Alkali 44g, it is warmed up to 90 ℃, slowly adds dropwise 55g of 37% formaldehyde aqueous solution, and the time of dropping is 0.5 hour, and dropwise is finished, continues to insulate reaction at 90 ℃ for 5 hours, cools down to 50 ℃ after reaction finishes, to Add 20g of epichlorohydrin dropwise to the reaction bottle, the dropping time is 0.5 hours, react at 50°C for 1 hour after dropping, then add 3g of urea to the reaction bottle, continue to react at 50°C for 0.5 hours, then add 60g Glacial acetic acid, stir well, and after cooling, a reactive nylon color-fixing agent with good acid resistance can be prepared. The color-fixing agent content is about 35%, and the pH value of the color-fixing agent (1% aqueous soluti...

Embodiment 2

[0024] Add 100g of phenol, 50g of sodium phenolsulfonate, 50g of naphtholsulfonic acid, 260g of water, 0.5g of boric acid, and slowly add 30% liquid caustic soda 44g, it was heated up to 90°C, and 55g of 37% formaldehyde aqueous solution was slowly added dropwise, and the dropwise addition time was 0.5 hours. Add 20g of epichlorohydrin dropwise to the bottle for 0.5 hours, and react at 50°C for 1 hour after dropping, then add 3g of melamine into the reaction bottle, continue to react at 50°C for 0.5 hours, then add 62g of formic acid , stir evenly, and after cooling, a reactive nylon color-fixing agent with good acid resistance can be prepared. The content of the color-fixing agent is about 35%, and the pH value of the color-fixing agent (1% aqueous solution) is 2.8.

Embodiment 3

[0026] Add 100g of bisphenol S, 38g of sodium naphthalenesulfonate, 62g of sulfonated bisphenol A, 260g of water, 0.5g of boric acid, and slowly add 30% Liquid caustic soda 44g, it is heated up to 90 ℃, slowly drips 55g of 37% formaldehyde aqueous solution, dropwise time is 0.5 hour, dropwise is completed, continues to insulate and react at 90 ℃ for 10 hours, after the reaction finishes, cool down to 50 ℃, Add 20g of epichlorohydrin dropwise to the reaction bottle for 0.5 hours. After the drop, react at 50°C for 1 hour, then add 3g of potassium persulfate to the reaction bottle, and continue the reaction at 50°C for 0.5 hours , add 30g of glacial acetic acid and 30g of formic acid, stir well, and after cooling, a reactive nylon color-fixing agent with good acid resistance can be prepared. The content of the color-fixing agent is about 35%, and the pH value of the color-fixing agent (1% aqueous solution) is 3.2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com