Formaldehyde-free fixing agent for all-color-series reactive dyes as well as preparation method and use method of formaldehyde-free fixing agent

A technology of formaldehyde-free color-fixing agent and reactive dyes, which is applied in dyeing, textiles and papermaking, can solve problems such as obvious effects, and achieve the effects of convenient production and operation in the workshop, excellent fastness, and improved color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

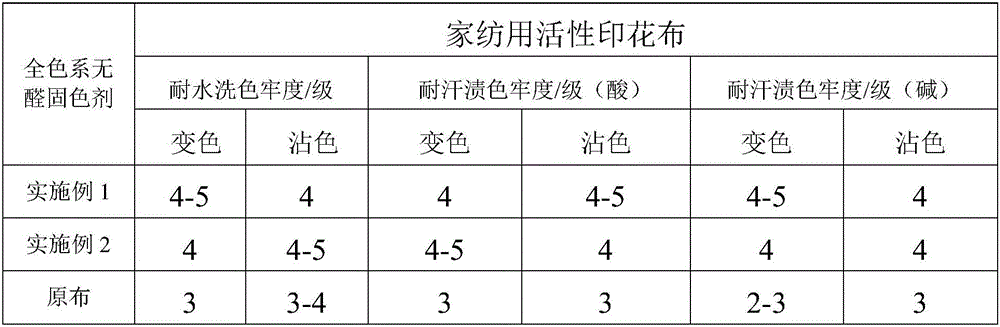

Examples

Embodiment 1

[0058] A formaldehyde-free color-fixing agent for full-color reactive dyes, which is prepared by compounding a first color-fixing agent and a second color-fixing agent at a weight ratio of 2:2.5.

[0059] Specifically, the compounding step can be to take a predetermined amount of the first color-fixing agent and add it to the reaction container, and then add a predetermined amount of the second color-fixing agent to the reaction container, and the temperature in the reaction container will rise after completion When the temperature reaches 40-50°C, start stirring to mix the first color-fixing agent and the second color-fixing agent evenly, and then compound them into the formaldehyde-free color-fixing agent for full-color reactive dyes.

[0060] The raw material components for the preparation of the first color fixing agent and the parts by weight of each component are: 12 parts of diallylamine, 15 parts of epichlorohydrin, 10 parts of N-vinylpyrrolidone, methacryloyl 65 parts...

Embodiment 2

[0073] A formaldehyde-free color-fixing agent for full-color reactive dyes, which is prepared by compounding a first color-fixing agent and a second color-fixing agent at a weight ratio of 1:2.

[0074] The specific compounding step can be to take a predetermined amount of the first color fixing agent and add it to the reaction container, and then add a predetermined amount of the second color fixing agent to the reaction container. After completion, the temperature in the reaction container Raise the temperature to 40-50°C, start stirring, and mix the first color-fixing agent and the second color-fixing agent evenly, and then compound them into the formaldehyde-free color-fixing agent for full-color reactive dyes.

[0075] Wherein the preparation raw material components of the first color fixing agent and the parts by weight of each component are: 15 parts of diallylamine, 18 parts of epichlorohydrin, 15 parts of N-vinylpyrrolidone, methacryloyl 70 parts of oxyethyltrimethyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com