Heating non-combustion type tobacco product heated through paper

A technology for heating non-combustible tobacco products, applied in the field of tobacco products, can solve problems such as large structural differences and complex preparation processes, and achieve the effects of meeting production needs, reducing harmful components, and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

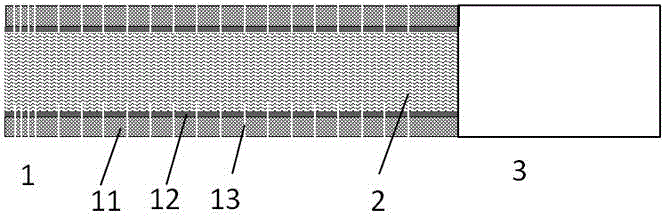

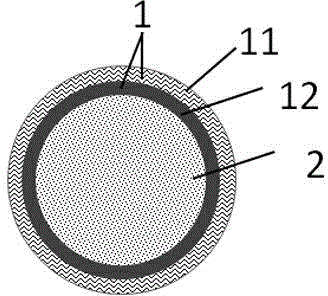

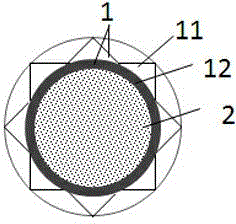

[0022] A heat-not-burn tobacco product, which consists of a composite wrapping layer (1), shredded tobacco filler (2) and a filter section (3). The composite wrapping layer (1) is composed of the cigarette paper burning layer (11) and the aluminum foil heat conduction layer (12) through a composite process, and holes (13) in a certain distribution are formed on the composite wrapping layer by mechanical punching. The burning layer is cigarette paper with a thickness of 1.0 mm, an air permeability of 60 CU, and a basis weight of 100 g / m 2 , the combustion regulator potassium citrate accounts for 5% of the mass of cigarette paper. The heat conduction layer is aluminum foil with a thickness of 0.05 mm. Then use mechanical drilling to punch holes in the composite wrapping layer, the hole diameter is 0.5 mm, and the number of holes is 10000 / m 2 .

[0023] The cigarette paper combustion layer is made by mixing the following raw materials, and the mass percentages of each raw mate...

example 2

[0025] A heat-not-burn tobacco product, which consists of a composite wrapping layer (1), shredded tobacco filler (2) and a filter section (3). The composite wrapping layer (1) is composed of the combustion layer (11) and the heat conduction layer (12) through a composite process, and holes (13) in a certain distribution are formed on the composite wrapping layer by laser drilling. The burning layer is cigarette paper with a thickness of 0.5 mm, an air permeability of 100 CU, and a basis weight of 50 g / m 2 , the combustion regulator potassium malate and sodium malate each account for 2.5% of the mass of the cigarette paper. The heat conduction layer is aluminum foil with a thickness of 0.05 mm. Then laser drilling is used to drill holes on the composite wrapping layer, the hole diameter is 0.2 mm, and the number of holes is 40000 / m 2 .

[0026] The combustion layer of the cigarette paper is made by mixing the following raw materials, and the mass percentages of each raw mat...

example 3

[0028] A heat-not-burn tobacco product, which consists of a composite wrapping layer (1), shredded tobacco filler (2) and a filter section (3). The composite wrapping layer (1) is composed of the combustion layer (11) and the heat conduction layer (12) through a composite process, and holes (13) in a certain distribution are formed on the composite wrapping layer by electrostatic drilling. The burning layer is cigarette paper with a thickness of 0.5 mm, an air permeability of 100 CU, and a basis weight of 50 g / m 2 , the combustion regulator sodium alginate accounted for 1.0% of the mass of cigarette paper. The heat conduction layer is aluminum foil with a thickness of 0.05 mm. Then use electrostatic drilling to punch holes in the composite wrapping layer, the hole diameter is 0.1 mm, and the number of holes is 80000 / m 2 .

[0029] The combustion layer of the cigarette paper is made by mixing the following raw materials, and the mass percentage of each raw material component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com