Method and apparatus for biomass ebullition, gasification and combustion

A technology of combustion device and combustion method, which is applied in the direction of combustion method, fluidized bed combustion equipment, fuel burned in a molten state, etc., and can solve the problems of no biomass gasification combustion device, increased use cost of combustion furnace, inconvenient use, etc. , to achieve the effect of high temperature, high temperature and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

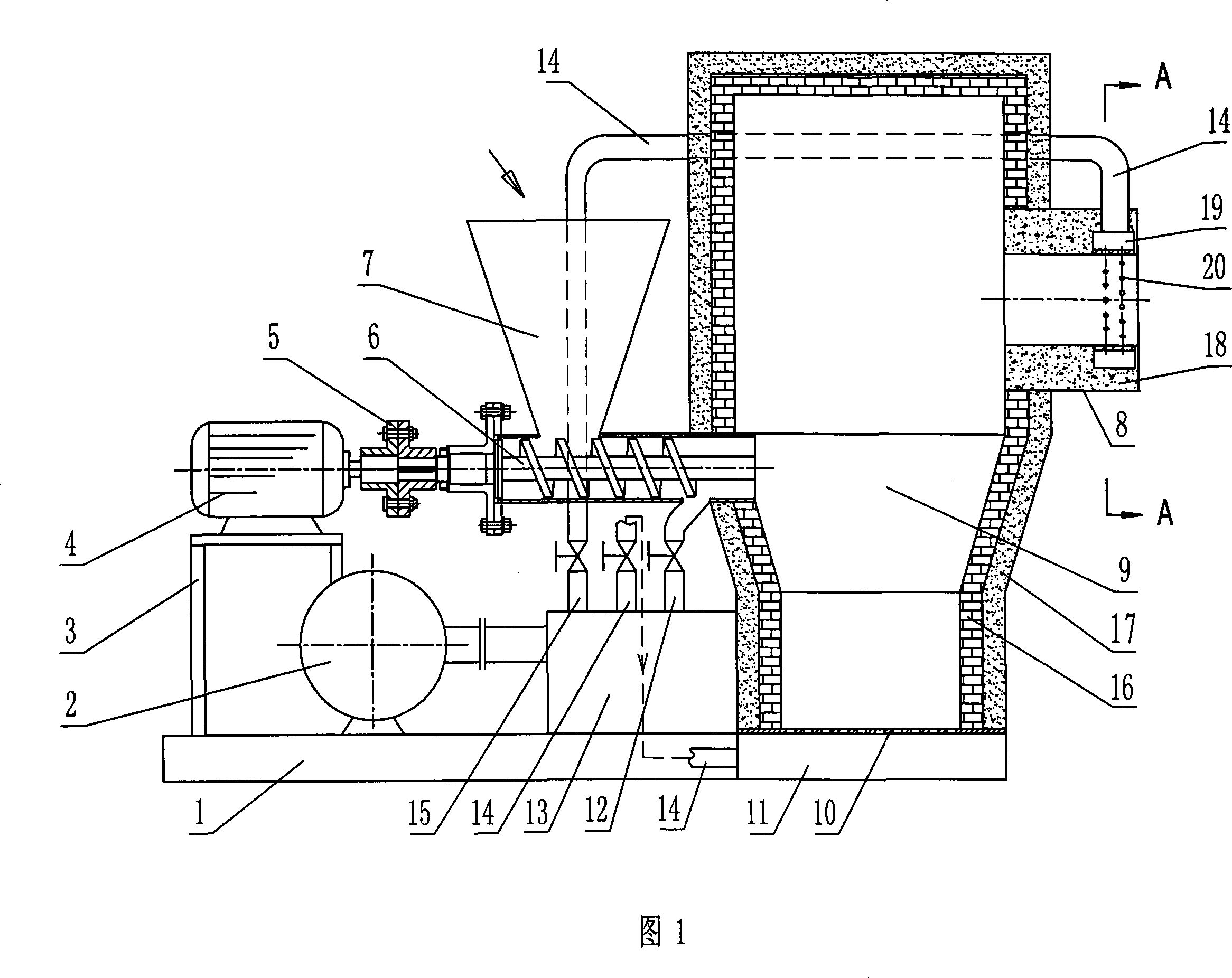

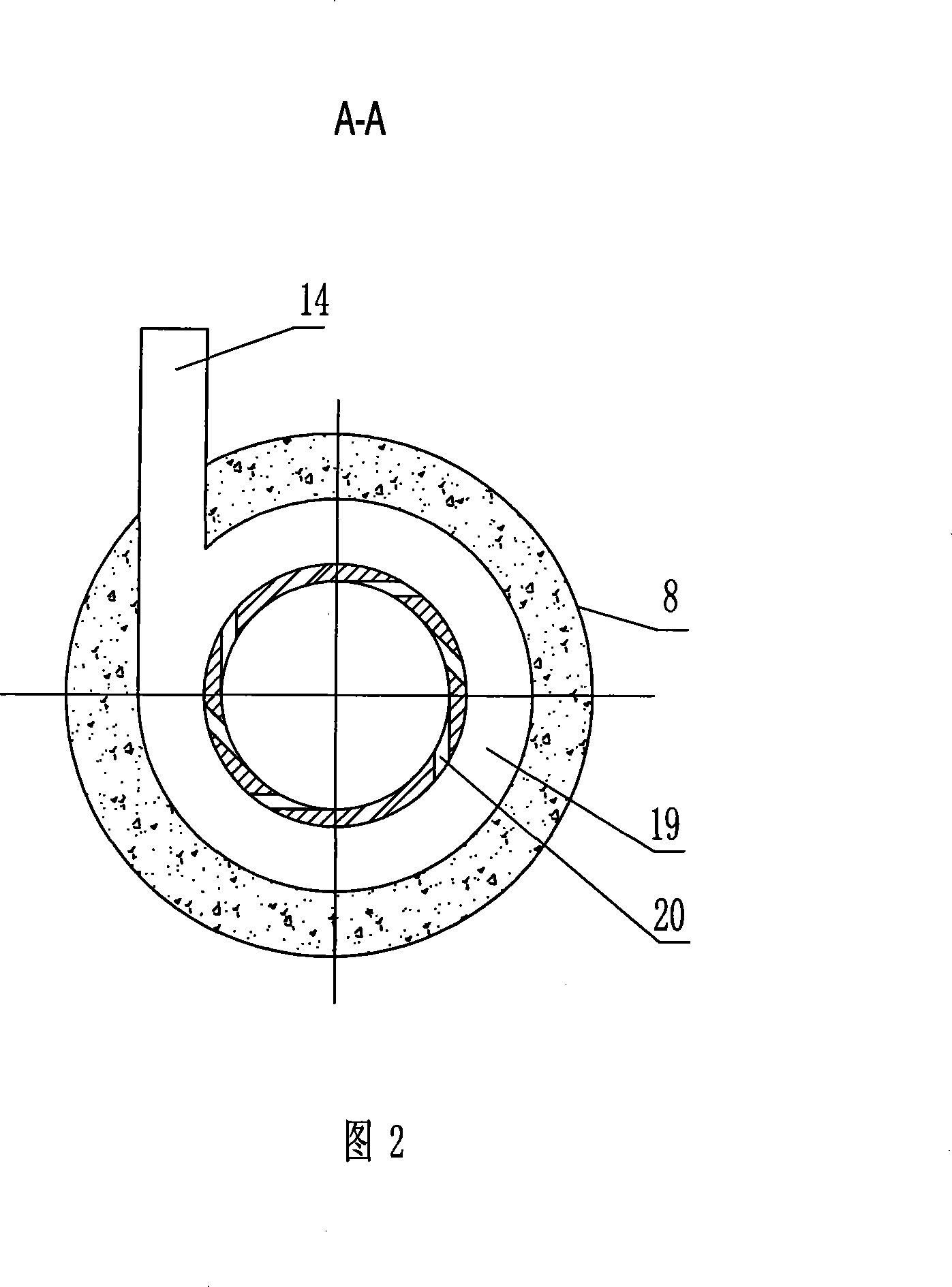

[0024] Figures 1 and 2 show biomass boiling gasification combustion devices, including a base 1, a feeding mechanism, an air supply mechanism, and a gasification combustion chamber 9 for biomass boiling gasification, and the chamber of the gasification combustion chamber 9 The wall is mainly composed of high alumina refractory brick inner lining 16 and aluminum silicate fiber outer lining 17 . The side of the base 1 is fixed with an equal pressure box 11, the top of the equal pressure box is an air distribution plate 10 with a tuyere, the gasification combustion chamber 9 is arranged on the air distribution plate 10, and the equal pressure box 11 passes through the The tuyere on the wind plate communicates with the gasification combustion chamber 9. A gas burner 8 for high-temperature gas discharge and combustion is provided on the middle and upper part of the side wall of the gasification combustion chamber 9, and an annular air duct 19 is provided at the outlet of the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com