Testing device for direct-current (DC) resistance of cable conductor

A technology for DC resistance testing and cable conductors, applied in measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve problems such as large contact resistance, large current loss, data dispersion, and large volatility. Achieve the effect of reducing contact resistance, reducing cable cost and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

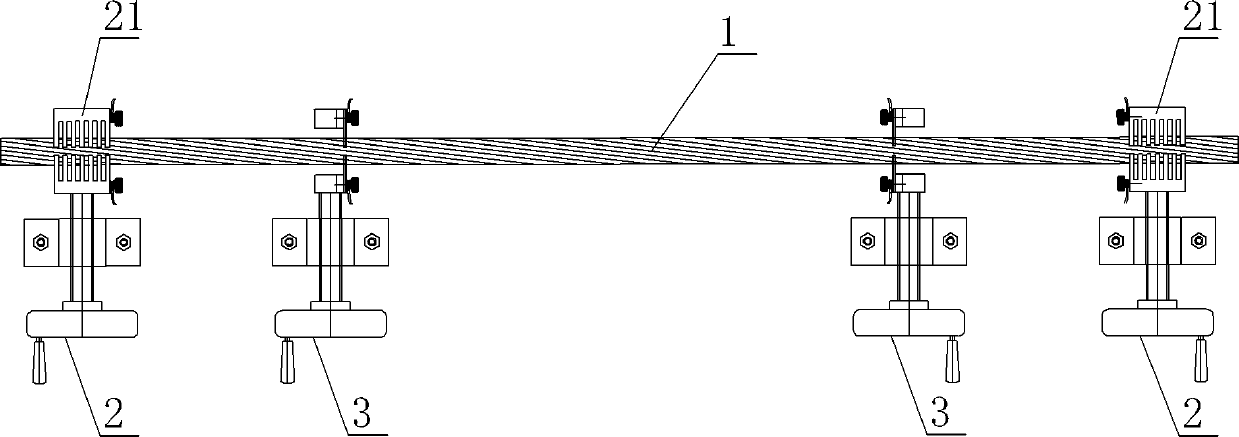

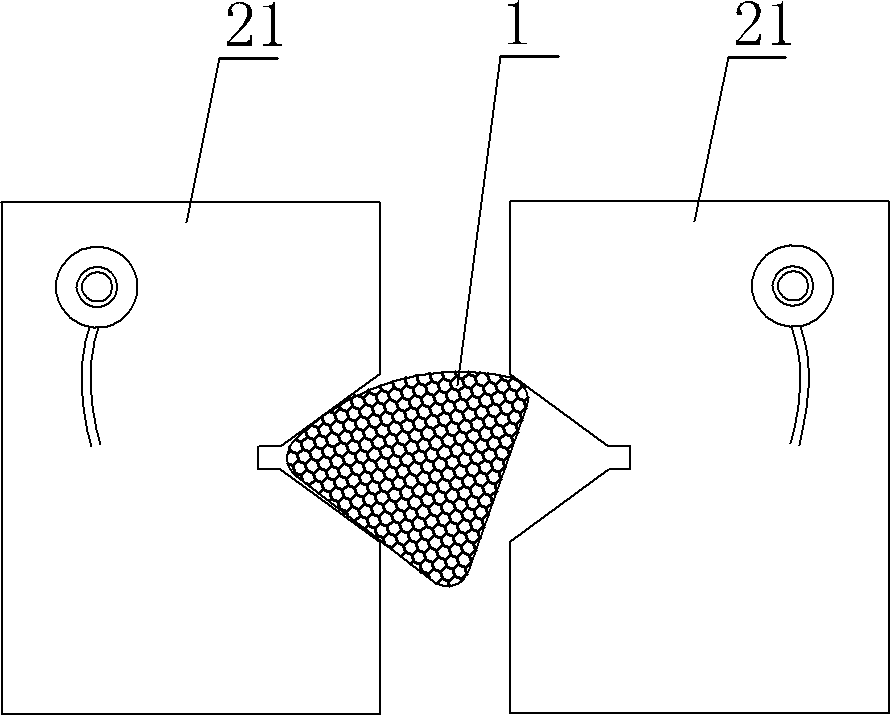

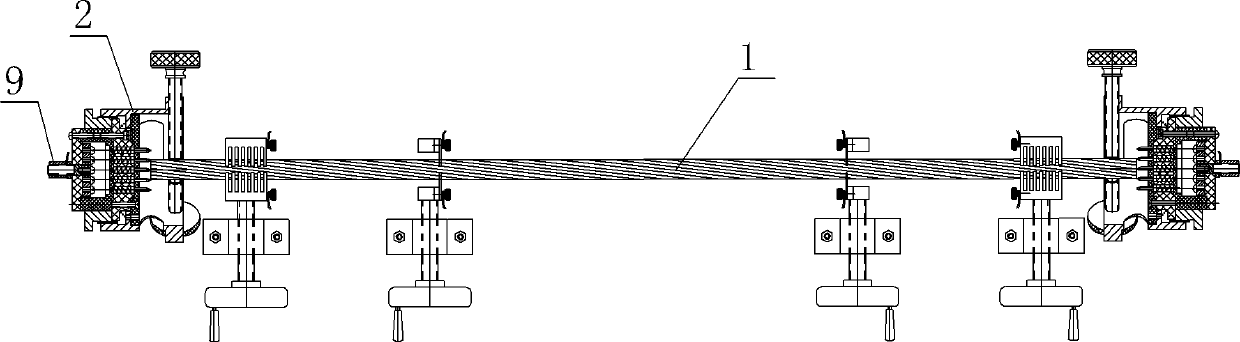

[0019] image 3 Shown is the cable conductor DC resistance testing device of the present invention, including two end face current input fixtures respectively arranged at the two ends of the testing device, as Figure 4 with Figure 5 As shown, the end face current input fixture includes a cap-shaped base 2, and the base 2 is provided with a clamping device and a current introduction device, and the current introduction device includes a 16 at the bottom of the base 2 The root tip 3 , the tip 3 has a needle-shaped tip, and the tip of the tip 3 protrudes from the inner side of the bottom of the base 2 . The top 3 is processed into a pointed needle shape from red copper, with a diameter of 3mm and a length of 12mm. These tips form a plurality of contact points to the pre-twisted conductor, which are uniformly arranged in the shape of a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com