Investment casting pattern manufacture

a technology of investment casting and pattern, applied in the field of investment casting, can solve the problems of difficult manufacturing of fine features, unsatisfactory internal features of parts, and associated cost of engine efficiency, and achieve the effect of improving engine efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

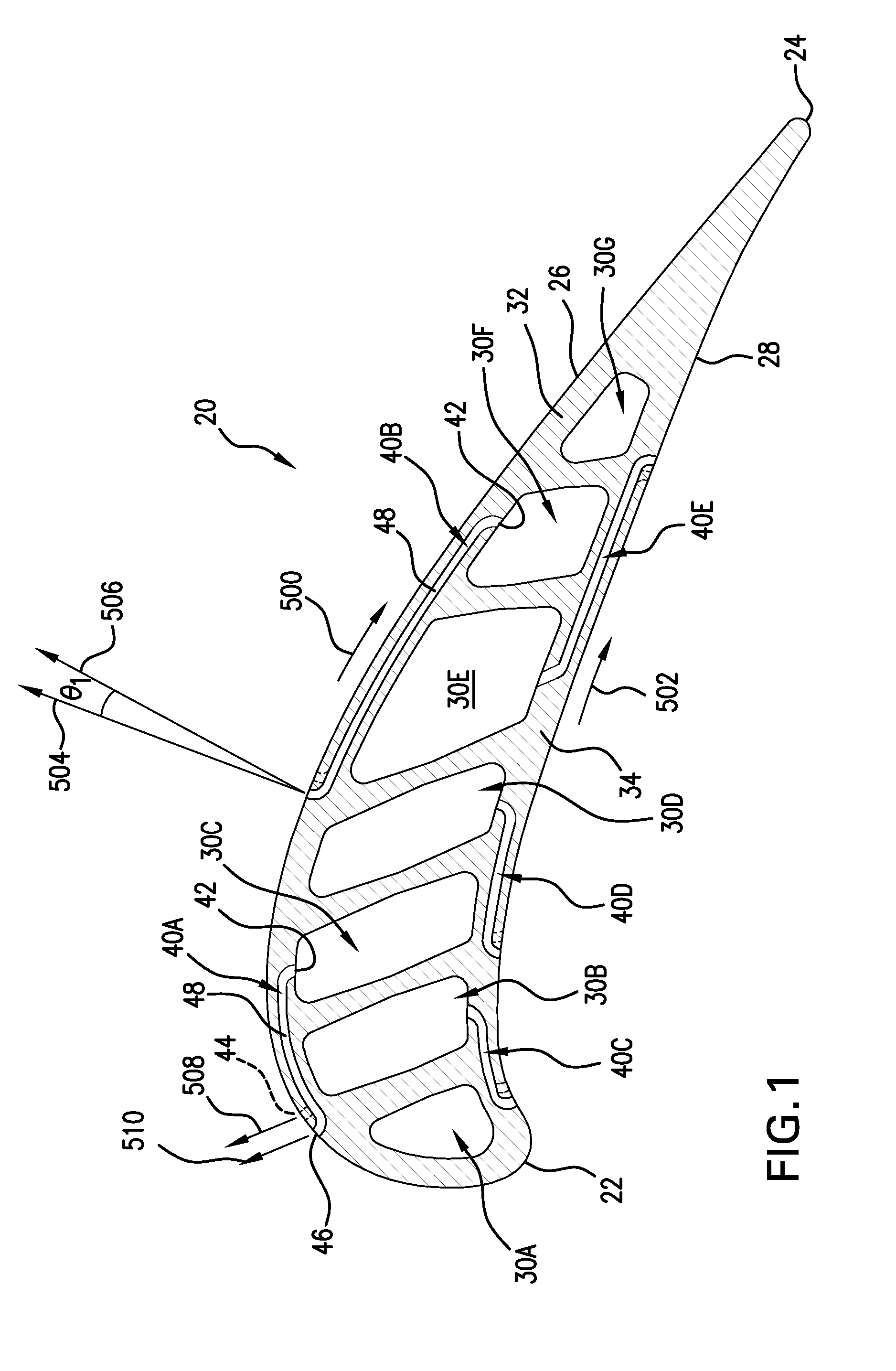

[0018]FIG. 1 shows an exemplary airfoil 20 of a gas turbine engine element. An exemplary element is a blade wherein the airfoil is unitarily cast with an inboard platform and attachment root for securing the blade to a disk. Another example is a vane wherein the blade is unitarily cast with an outboard shroud and, optionally, an inboard platform. Other examples include seals, combustor panels, and the like. The exemplary airfoil 20 has a leading edge 22 and a trailing edge 24. A generally convex suction side 26 and a generally concave pressure side 28 extend between the leading and trailing edges. In operation, an incident airflow is split into portions 500 and 502 along the suction and pressure sides (surfaces) 26 and 28, respectively.

[0019] The exemplary airfoil 20 includes an internal cooling passageway network. An exemplary network includes a plurality of spanwise extending passageway legs 30A-30G from upstream to downstream. These legs carry one or more flows of cooling air (e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com