Garbage incinerator circulating gas inlet and automatic falling intelligent control system

An intelligent control system and waste incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as large land occupation, groundwater pollution, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

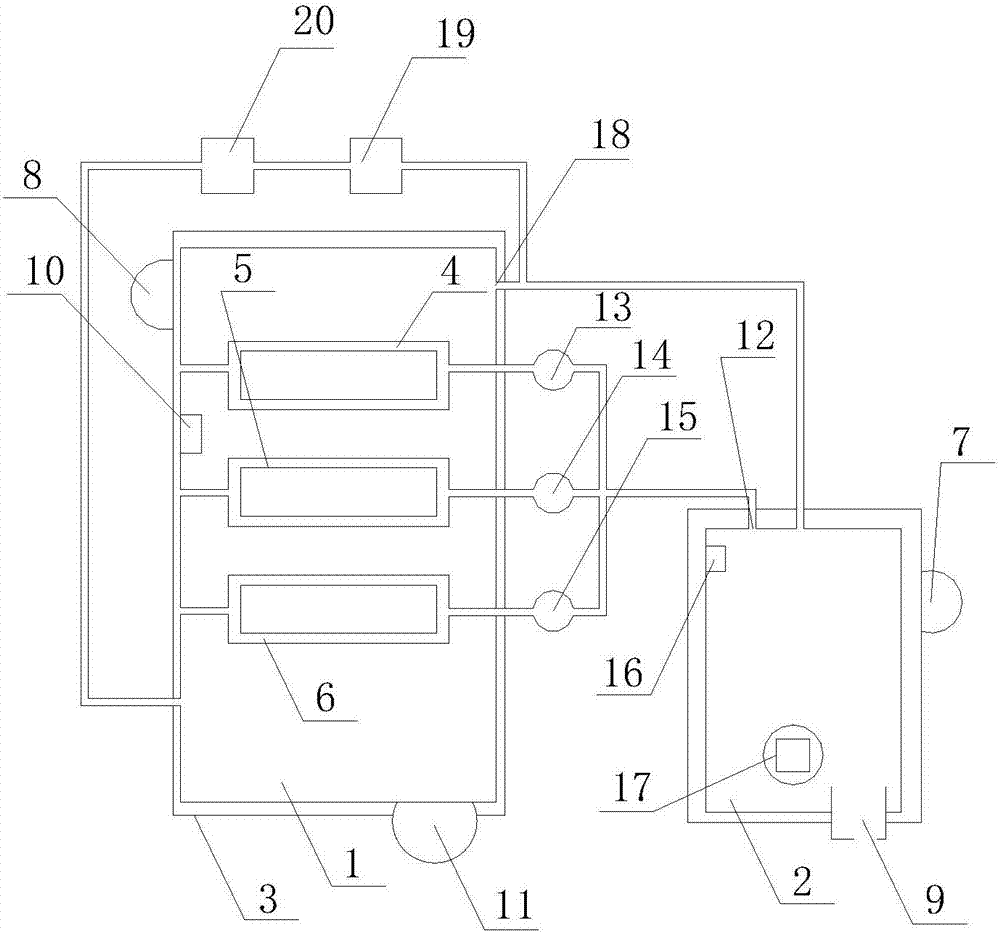

[0028] Such as figure 1 , figure 2 as shown, figure 1 , figure 2 A garbage incinerator cycle air intake and automatic blanking intelligent control system proposed by the present invention

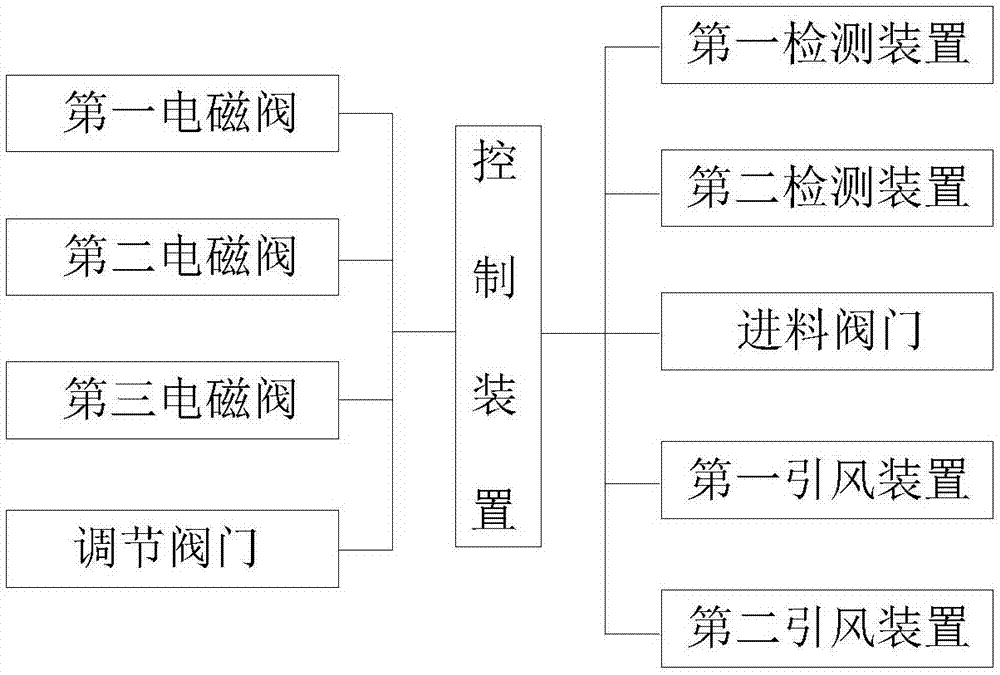

[0029] refer to figure 1 , figure 2 , the garbage incinerator cycle air intake and automatic blanking intelligent control system proposed by the present invention includes: a first cavity 1, a second cavity 2, a housing 3, a first detection device 10, a second detection device 16, a control device;

[0030]The first cavity 1 is set inside the housing 3, and a gas channel for gas circulation is formed between the outer wall of the first cavity 1 and the inner wall of the housing 3; the first pipeline circuit is arranged in sequence from top to bottom in the first cavity 1 4. The second pipeline loop 5, the third pipeline loop 6, the first pipeline loop 4, the second pipeline loop 5, and the third pipeline loop 6 are all connected to the gas channel through the pipeline, and the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com