A control method for a regenerative burner

A control method and burner technology, applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve problems such as insufficient combustion, abnormal ignition, and inappropriate air-fuel ratio, so as to improve the success rate of ignition, The effect of better combustion state and lower probability of detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

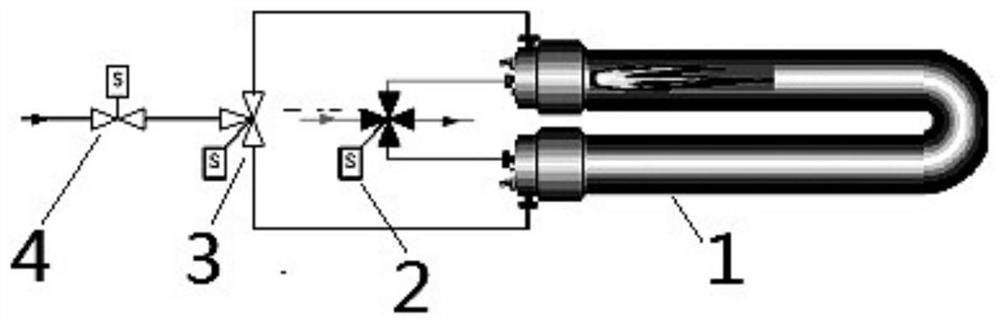

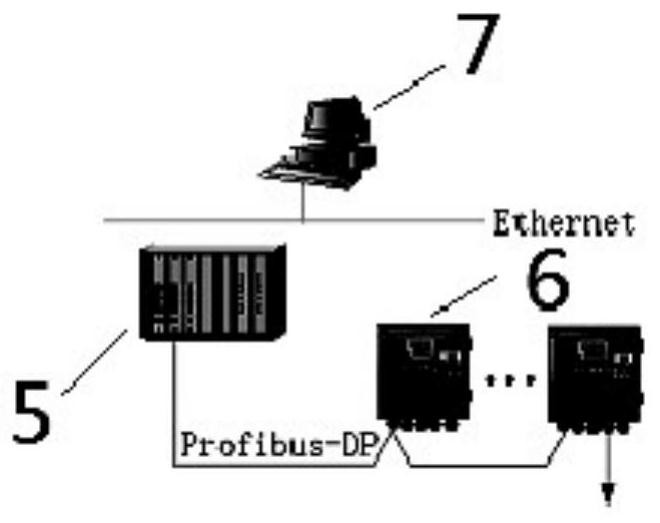

[0046] A control method of a regenerative burner in this embodiment divides the working state of the regenerative burner into an ignition mode and a normal working mode, and the two modes are judged and completed by the control program controlled by the burner:

[0047] 1. Mode judgment:

[0048] (1) Determine whether the actual value PV of the exhaust gas temperature of the air reversing valve is normal temperature or less than the set value X. If this condition is met, the regenerative burner will automatically enter the ignition mode, and the set value X is 200°C;

[0049](2) In the ignition mode, it is judged that after each reversing of the air-gas reversing valve, the air exhaust temperature can exceed the set value SP, and when the time to reach the SP value is less than T4, the regenerative burner will automatically enter the normal state. Working mode, the set point SP is 240°C, and the time T4 is 4min;

[0050] In the normal working mode, the heat storage capacity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com