Method for cooperatively treating powder and sludge waste by using cement kiln

A technology for co-processing and waste, applied in the field of waste treatment, can solve the problem of not being able to effectively apply PTA sludge and cracking catalyst powder waste, and achieve the goal of ensuring incineration temperature, ensuring stability, and preventing secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

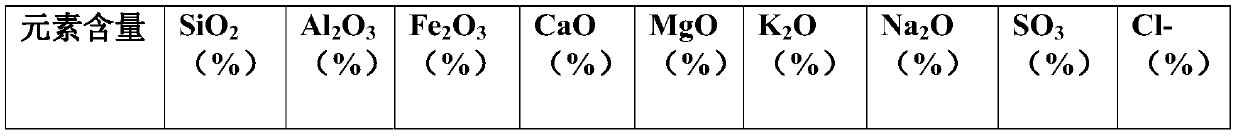

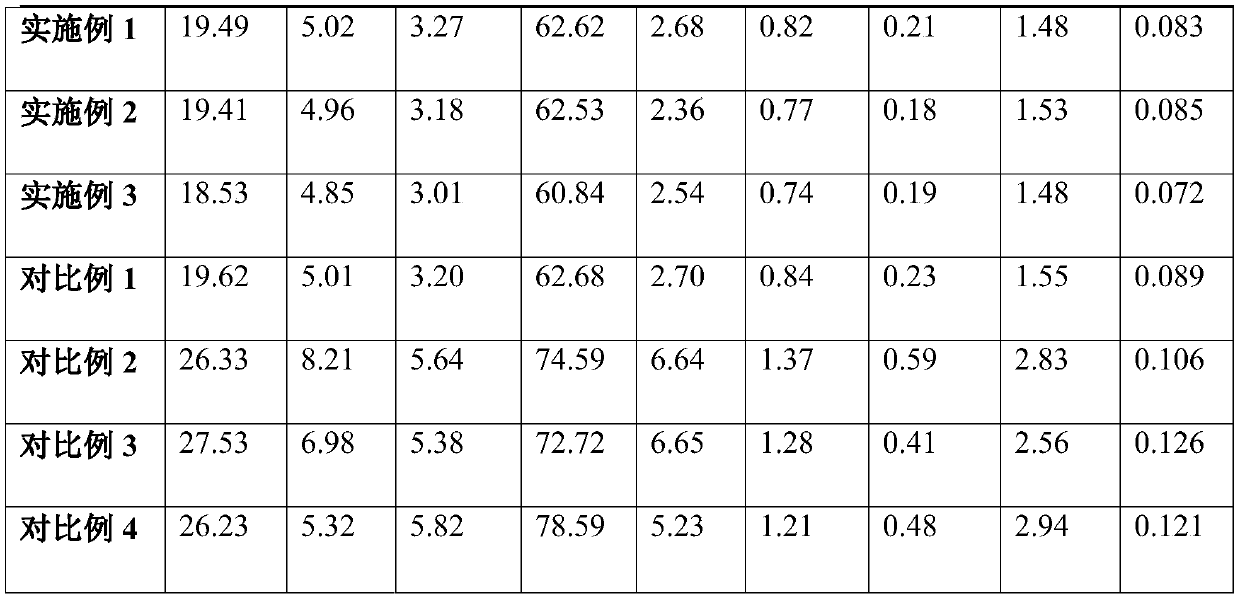

Examples

Embodiment 1

[0040] Embodiment 1-a kind of method utilizing cement kiln cooperative processing powder class and sludge class waste, comprises the steps:

[0041](1) Pre-treatment of sludge waste

[0042] After the PTA sludge waste with a moisture content of 55% is crushed, the combustion-supporting mixture is added to stir and mix at 30°C to obtain the PTA sludge mixed waste, which is homogenized and stored, and the PTA sludge waste is disposed of The scale is 70t / d; the combustion-supporting mixture is formed by mixing rice husk ash and rice bran powder at a mass ratio of 1:1:3;

[0043] (2) Pre-treatment of powder waste

[0044] The spent catalyst powder waste with a moisture content of 5% is magnetically separated by a magnetic separation device to obtain two sets of spent catalyst powder waste with different metal content and magnetic properties, which are homogenized separately Storage, waste catalyst powder waste disposal scale is 40t / d; the Cl of spent catalyst powder waste with l...

Embodiment 2

[0049] Embodiment 2-a kind of method utilizing cement kiln cooperative processing powder class and sludge class waste, comprises the steps:

[0050] A. Pre-treatment of sludge waste

[0051] (1) After the PTA sludge waste with a moisture content of 65% is crushed by a crusher until the particle size is <3 mm, the combustion-supporting mixture is added to stir and mix at 38 ° C. The addition of the combustion-supporting mixture is PTA sludge. 5% of the mud waste quality, stir evenly to obtain PTA sludge mixed waste; the disposal scale of PTA sludge waste is 60t / d; 1:5:5 mixed;

[0052] (2) Transport the PTA sludge mixed waste in step (1) to the sludge receiving storage tank via a sealed transport vehicle, and homogenize and store it;

[0053] (3) The PTA sludge mixed waste is transported to the sludge spray gun by the thick slurry pump at the bottom of the sludge receiving storage tank, and sprayed into the kiln tail smoke chamber of the rotary cement kiln by the sludge spray...

Embodiment 3

[0064] Embodiment 3-a kind of method utilizing cement kiln cooperative processing powder class and sludge class waste, comprises the steps:

[0065] A. Pre-treatment of sludge waste

[0066] (1) After the PTA sludge waste with a moisture content of 60% is crushed by a crusher until the particle size is <3 mm, the combustion-supporting mixture is added to stir and mix at 35 ° C. The addition of the combustion-supporting mixture is PTA sludge. 10% of the mud waste quality, stir evenly, obtain PTA sludge mixed waste; PTA sludge waste disposal scale is 50t / d; The combustion-supporting mixture is made of rice husk ash and rice bran powder with a mass ratio 1:1:5 mixed;

[0067] (2) Transport the PTA sludge mixed waste in step (1) to the sludge receiving storage tank via a sealed transport vehicle, and homogenize and store it;

[0068] (3) The PTA sludge mixed waste is transported to the sludge spray gun by the thick slurry pump at the bottom of the sludge receiving storage tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com