High-efficiency garbage pyrolysis device capable of accumulating heat and regulating temperature automatically

A technology for heat storage and temperature regulation and garbage, which is applied in the directions of combustion technology mitigation, greenhouse gas reduction, lighting and heating equipment, etc. The effect of falling, temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

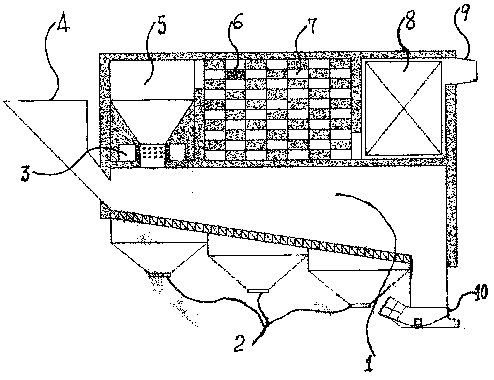

[0013] like figure 1 As shown, the self-storage and temperature-adjusting high-efficiency pyrolysis garbage device of the present invention includes a fan burning chamber 1, which is respectively connected with the air intake box 2, the garbage inlet 4, the flue gas outlet 9, and the slag discharge mechanism 10. A heat storage and adjustment chamber is provided between the flue gas outlet 9 and the fan firing chamber 1, and a number of heat storage blocks 6 are arranged in the heat storage and adjustment chamber, and each heat storage block 6 is spaced to form a number of fire grids through which the flue gas passes. 7. The fire grid is set in the discharge channel of the flame smoke in the fan combustion chamber, which can absorb or discharge the heat of the flame smoke, and adjust the temperature of stable incineration and the smoke. The fire grid is built with conventional high-temperature refractory bricks.

[0014] A secondary combustion chamber 5 is provided between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com