Efficient circular air inlet and automatic blanking control system of garbage incinerator

A technology of waste incinerator and control system, applied in incinerator, combustion method, combustion type, etc., can solve the problems of poor fertilizer quality, occupation, and low sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

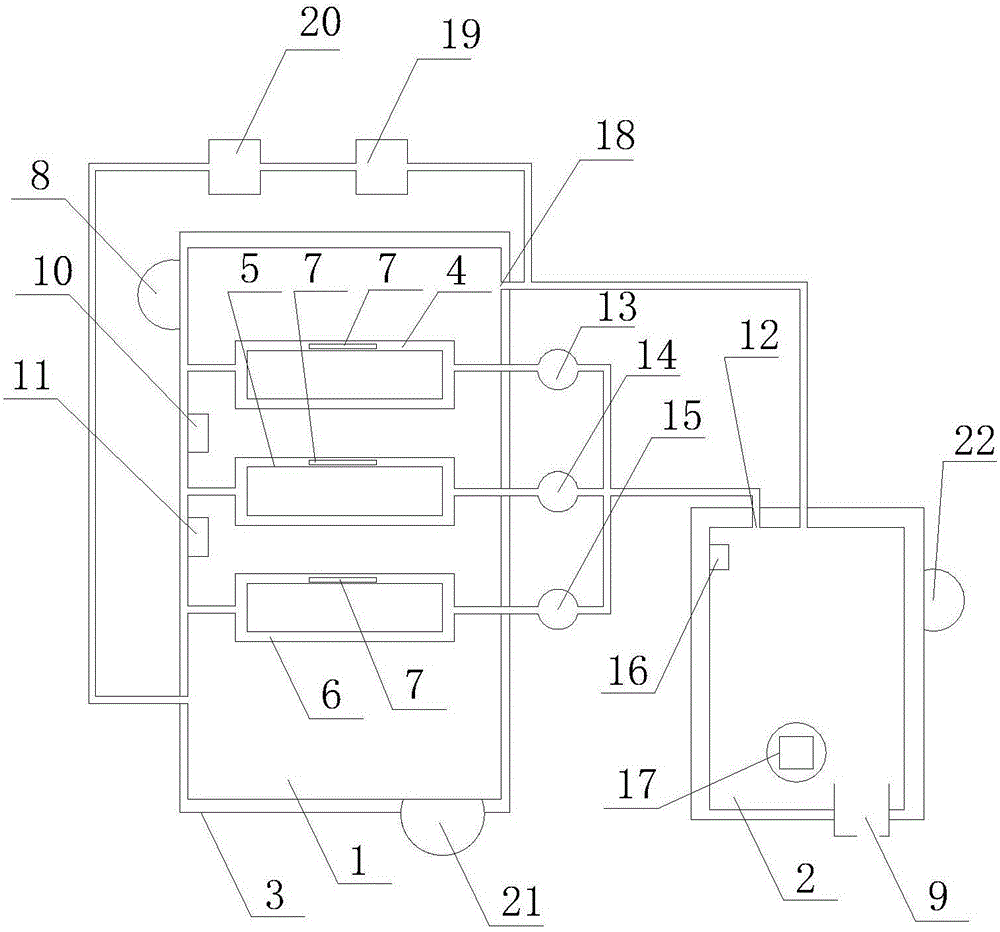

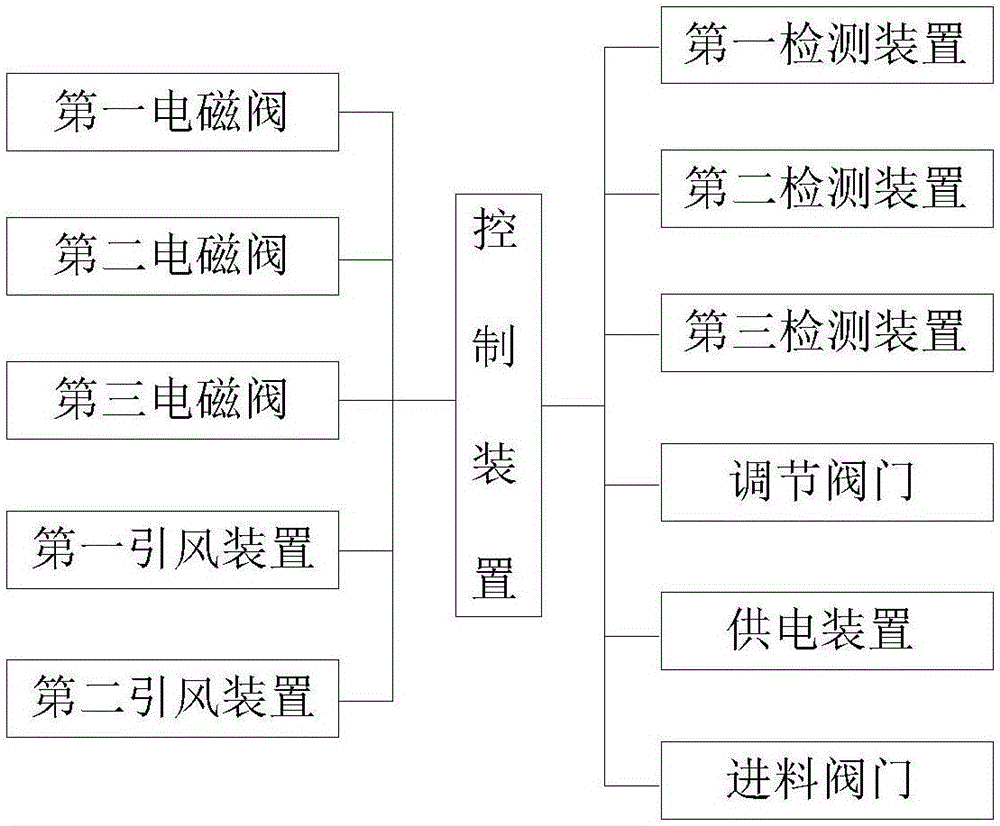

[0028] Such as figure 1 , figure 2 as shown, figure 1 , figure 2 It is a high-efficiency circulation air intake and automatic blanking control system for a waste incinerator proposed by the present invention.

[0029] refer to figure 1 , figure 2 , the waste incinerator high-efficiency circulation air intake and automatic blanking control system proposed by the present invention includes: a first cavity 1, a second cavity 2, a casing 3, a power supply device, and a control device;

[0030] The first cavity 1 is located inside the housing 3, and a gas channel for gas circulation is formed between the outer wall of the first cavity 1 and the inner wall of the housing 3; the outer wall of the housing 3 is provided with a first air induction device 8, the first air induction The wind device 8 is used to drive the gas flow in the gas passage; the first cavity 1 is sequentially provided with a first pipeline loop 4, a second pipeline loop 5, a third pipeline loop 6, a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com