Patents

Literature

44results about How to "Increase the blanking speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blanking system with constant-temperature control function

InactiveCN105674297AReduce the blanking speedIncrease the blanking speedIncinerator apparatusTemperature controlStopped work

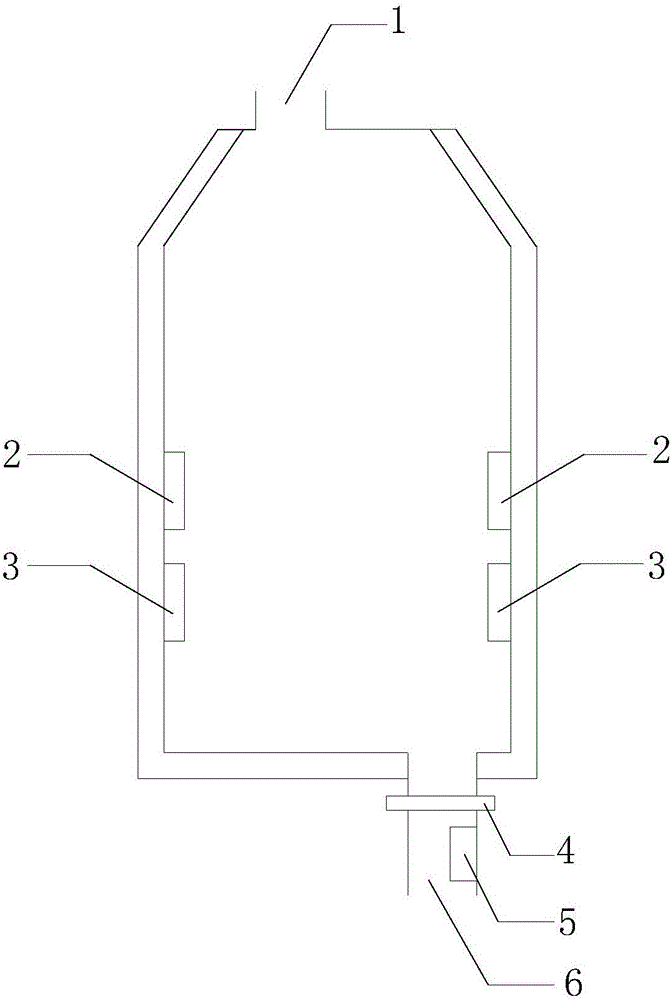

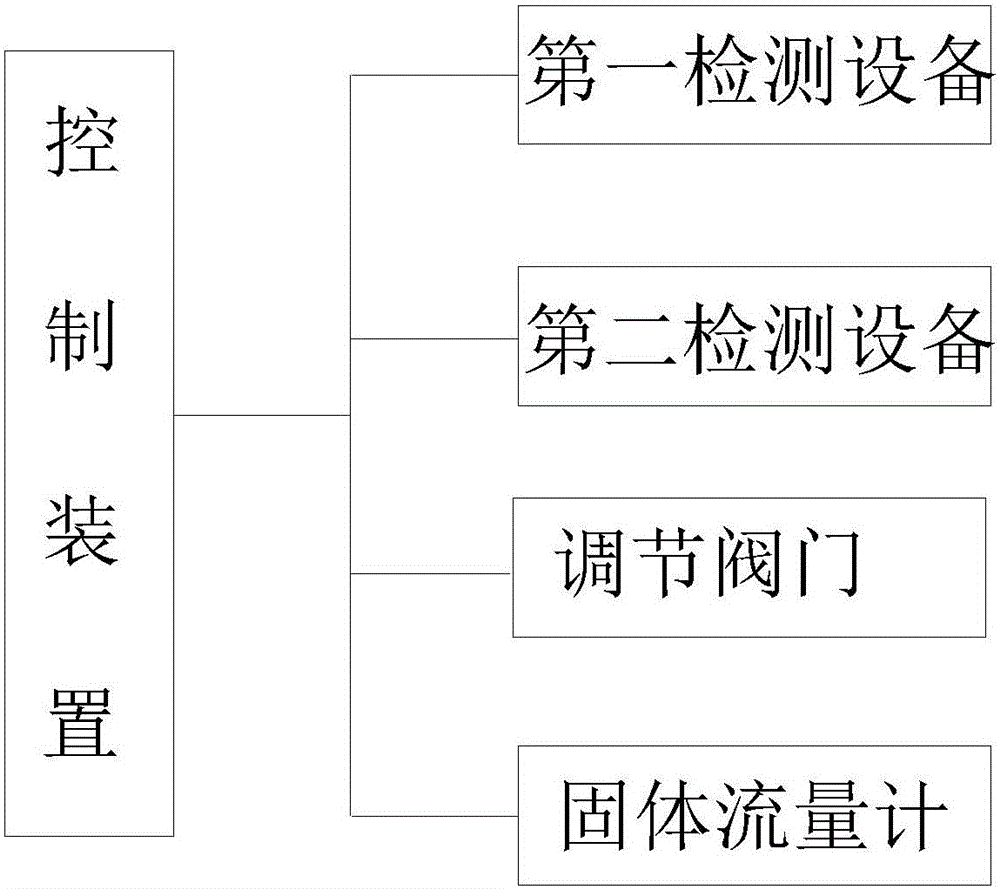

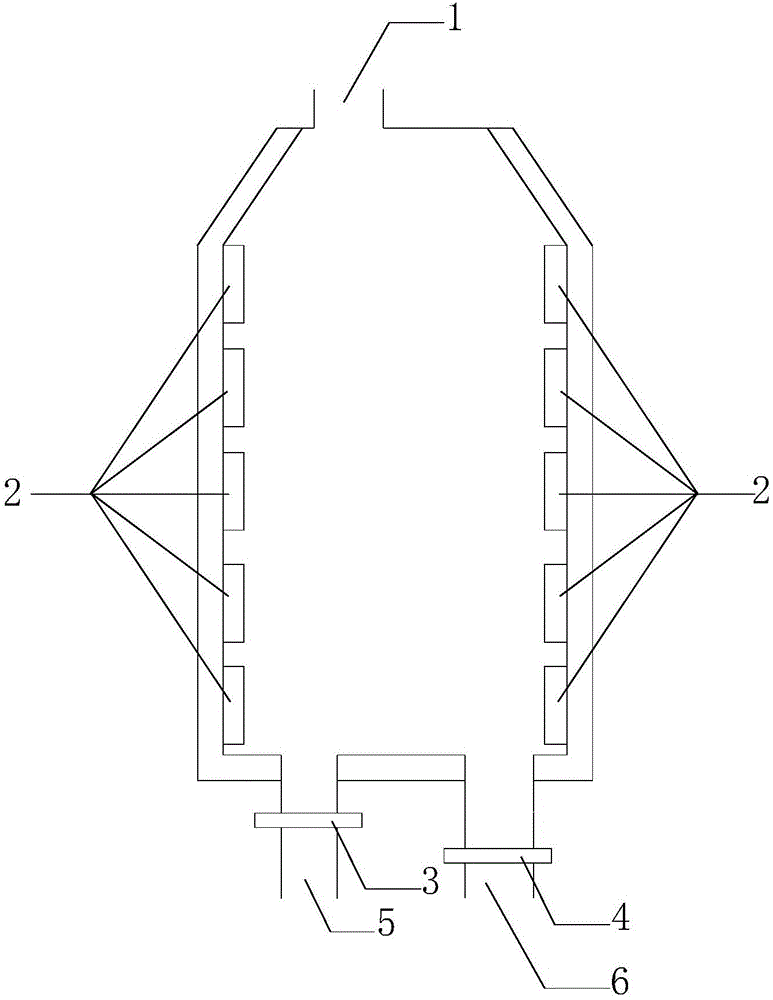

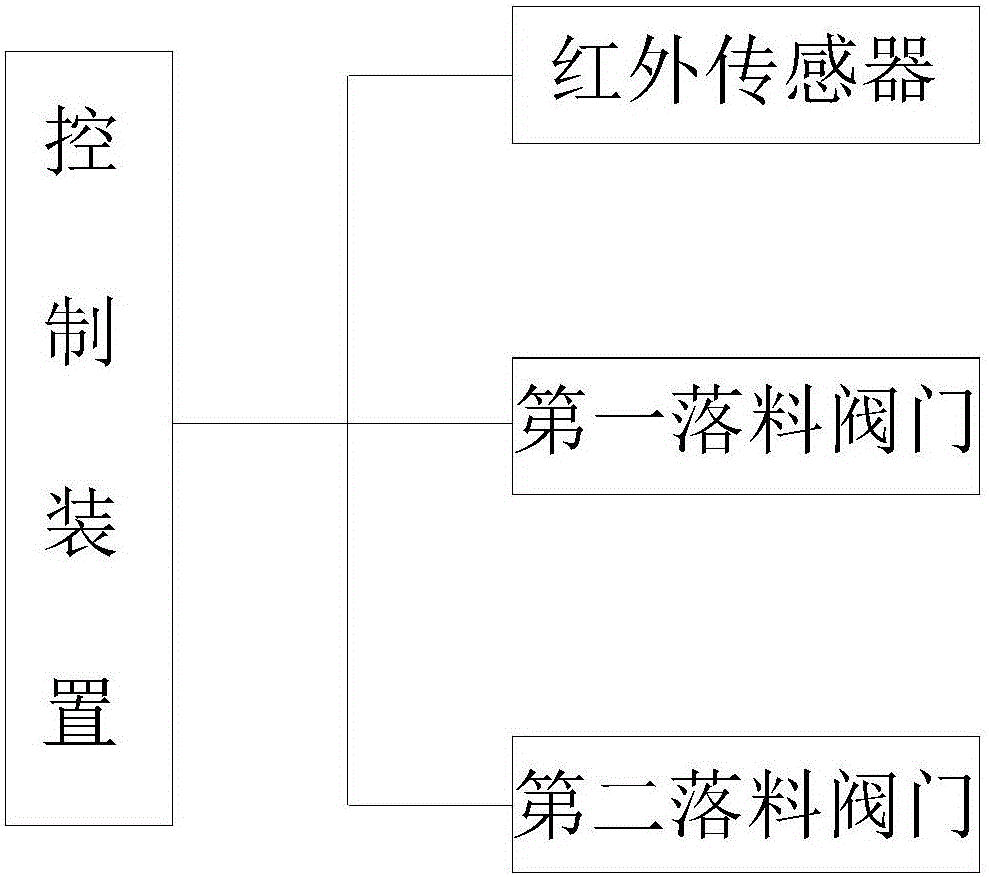

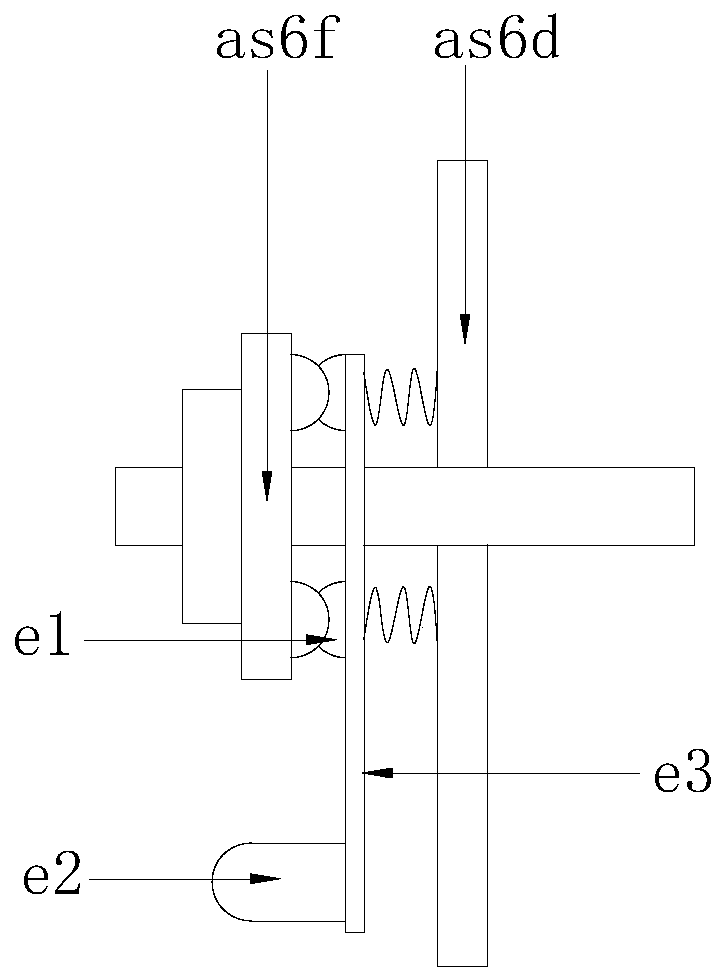

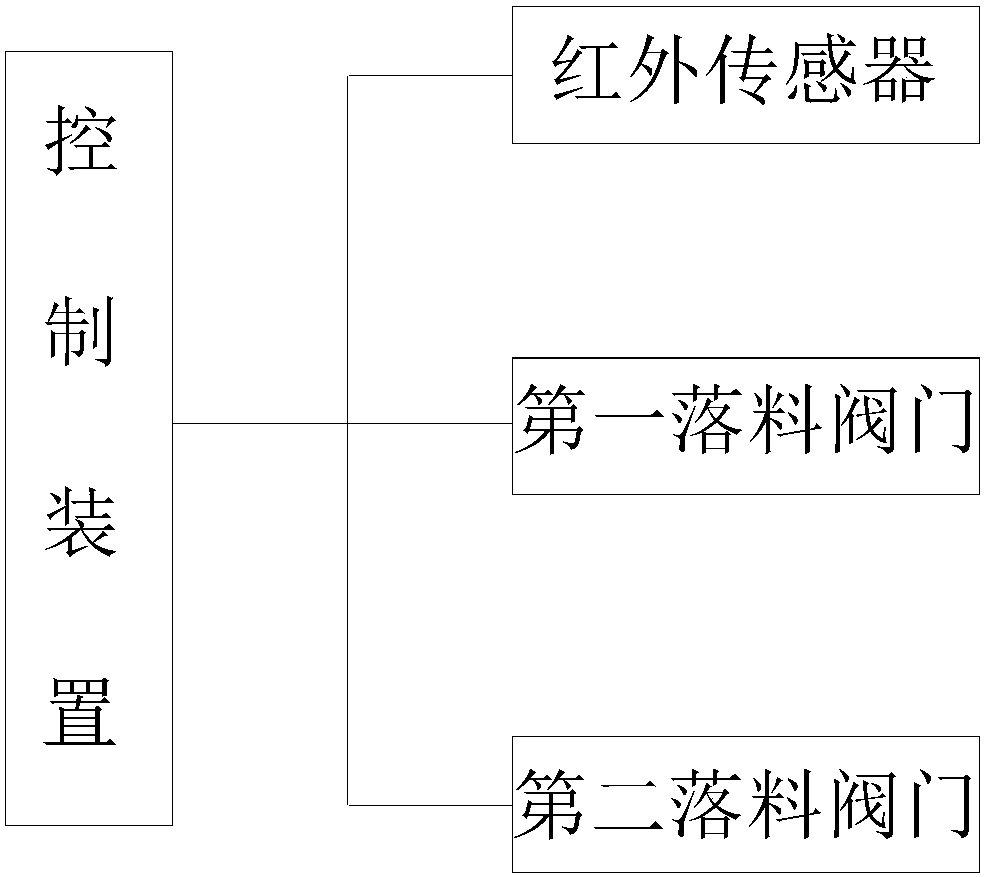

The invention discloses a blanking system with a constant-temperature control function. The blanking system comprises a combustion cavity, a first detection device, a second detection device, a blanking device and a control device, wherein a charge port for charge is arranged in the top of the combustion cavity, and a blanking port for blanking is arranged in the bottom of the combustion cavity; the first detection device is used for detecting a temperature value T1 at a first position in the combustion cavity; the second detection device is used for detecting a temperature value T2 at a second position in the combustion cavity; the blanking device is used for starting or stopping working according to an instruction of the control device; the control device is in communication connection with the first detection device, the second detection device and the blanking device; an ideal temperature difference value t is preset in the control device, and the control device is used for obtaining T1 and T2 trough the first detection device and the second detection device, and calculating an actual temperature difference value T according to T1 and T2; and the control device is used for calculating an error value X according to the ideal temperature difference value t and the actual temperature difference value T, and controlling the blanking device to work according to the error value X.

Owner:SINOBIOWAY BIOENVIRONMENT CO LTD

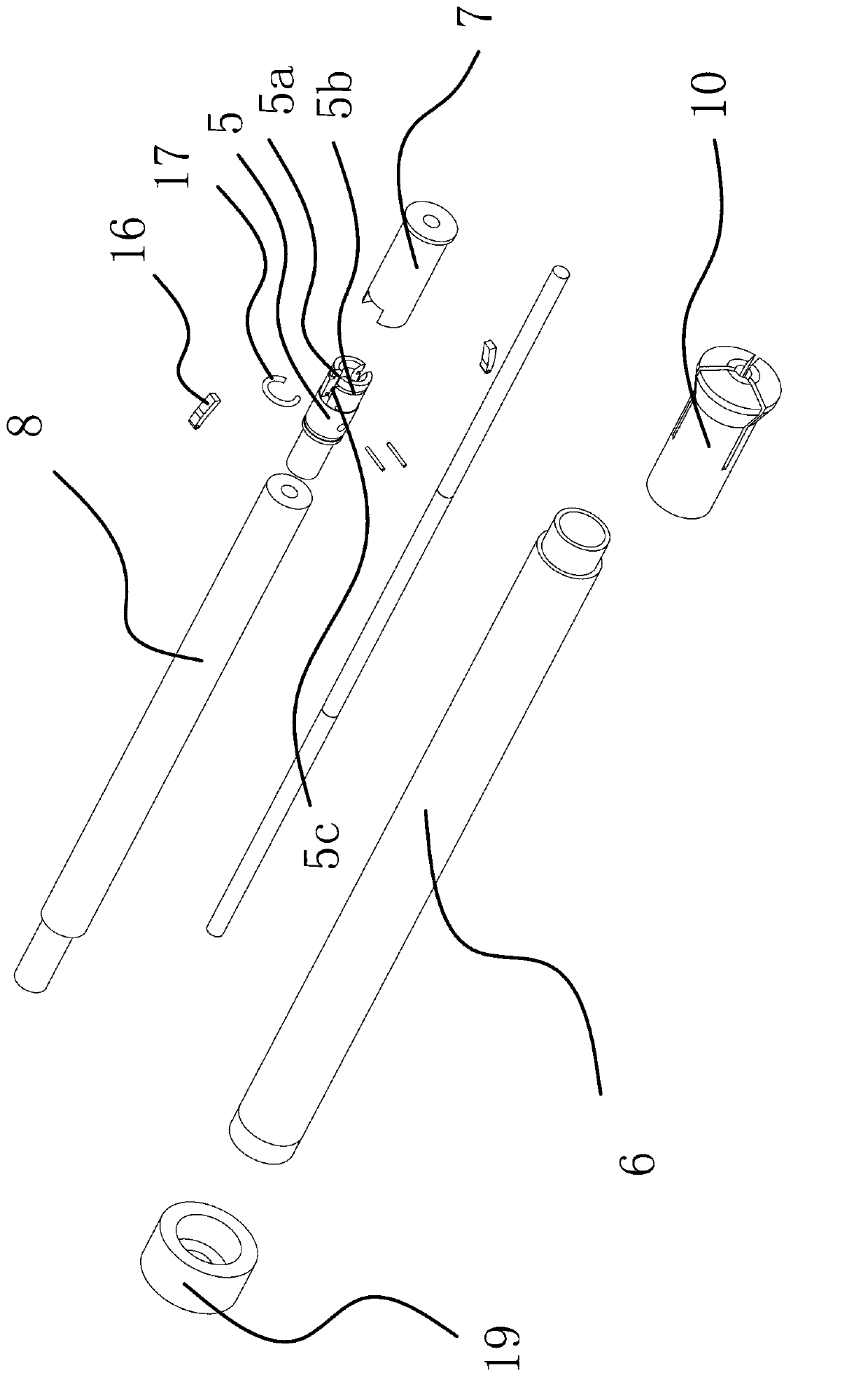

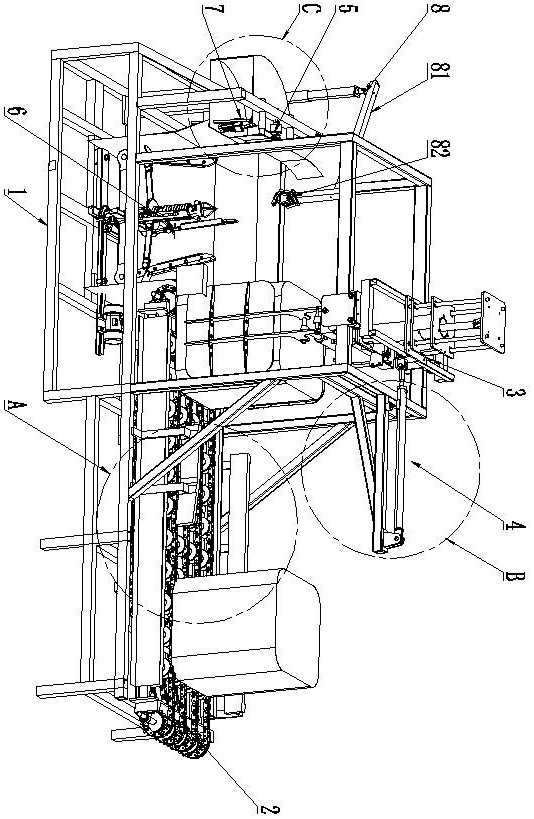

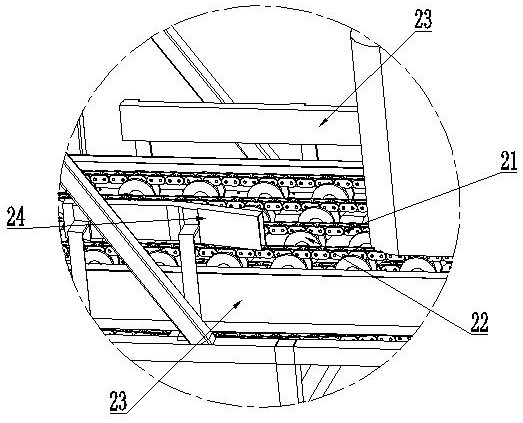

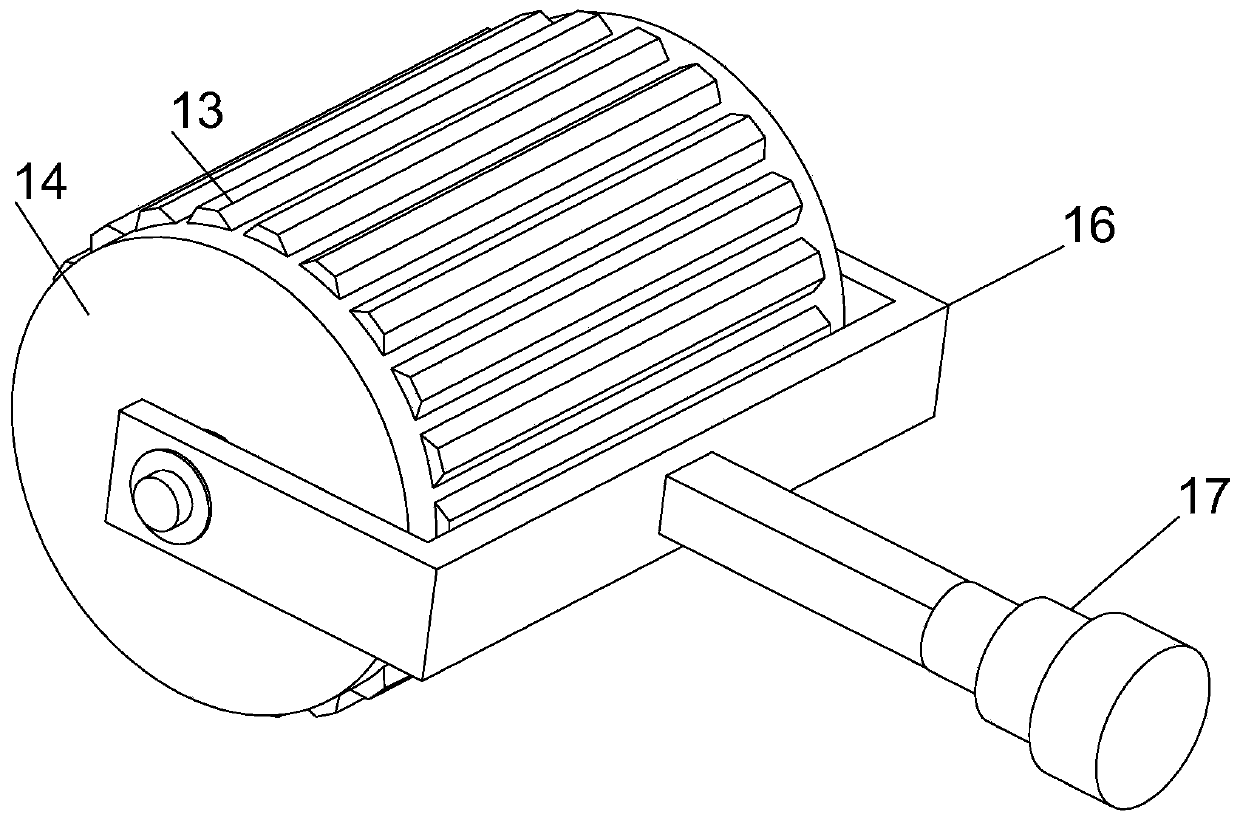

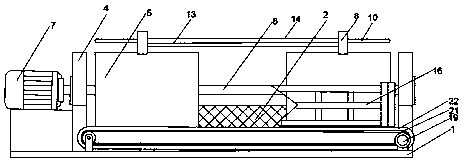

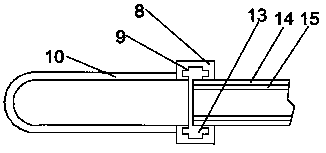

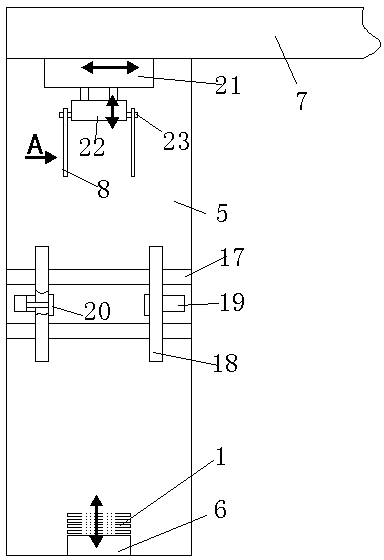

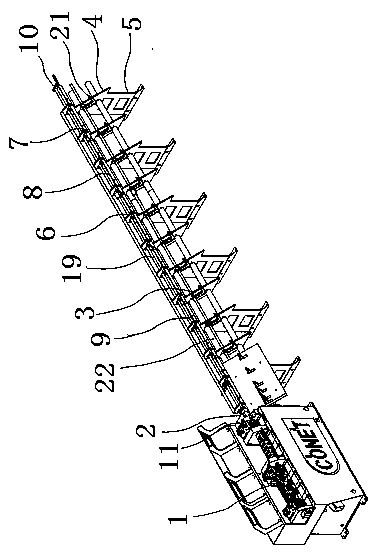

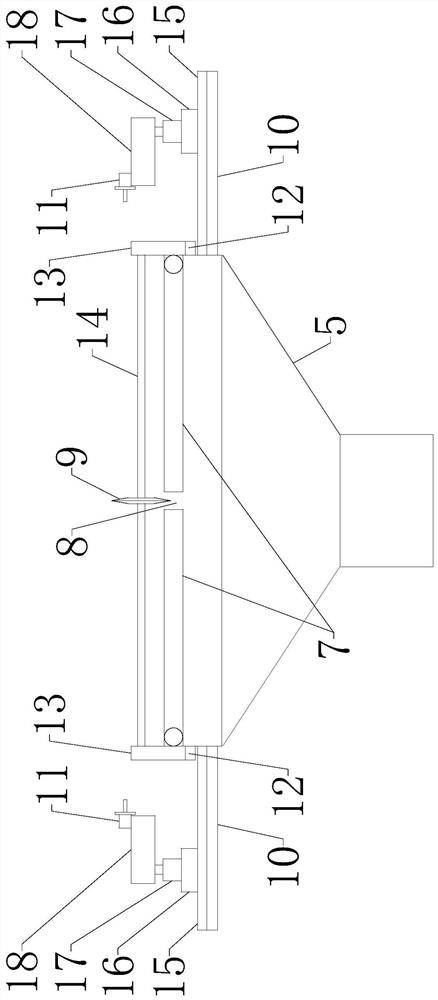

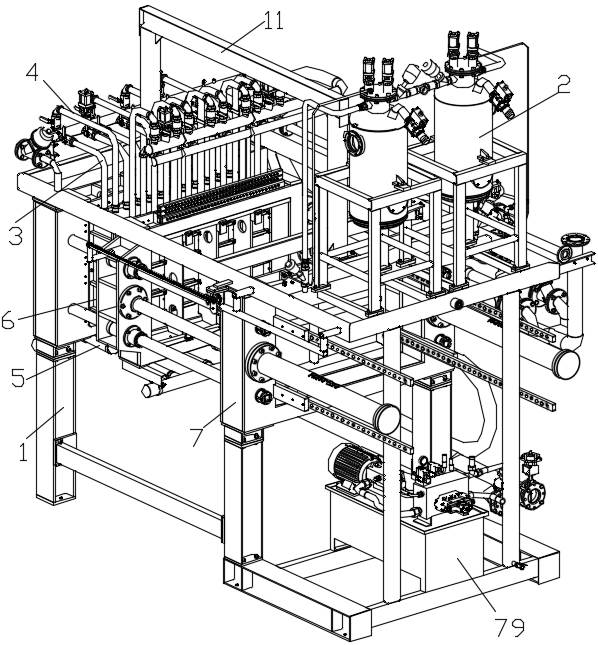

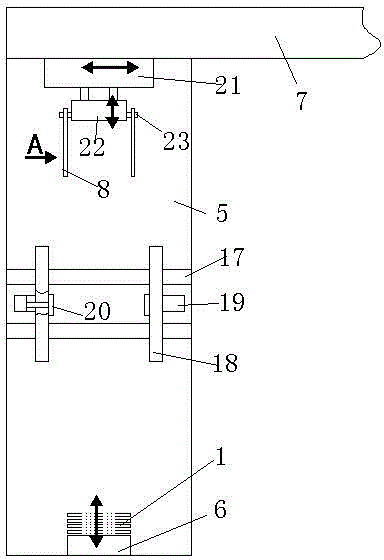

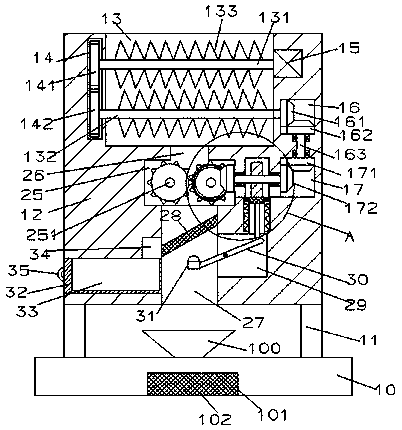

Full-automatic numerically-controlled machine tool for shafts

ActiveCN103273366APrecise positioningImprove work efficiencyMetal working apparatusNumerical controlEngineering

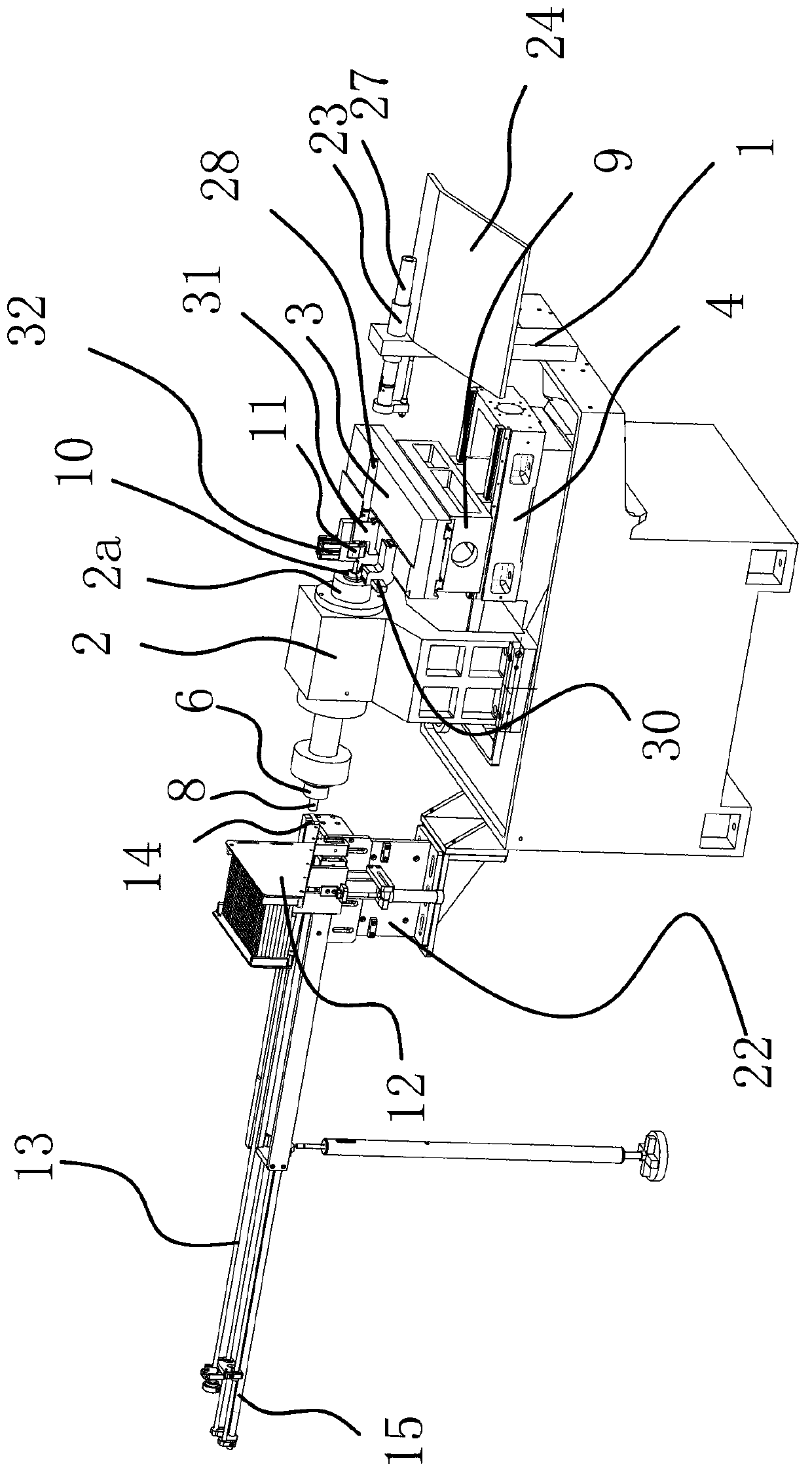

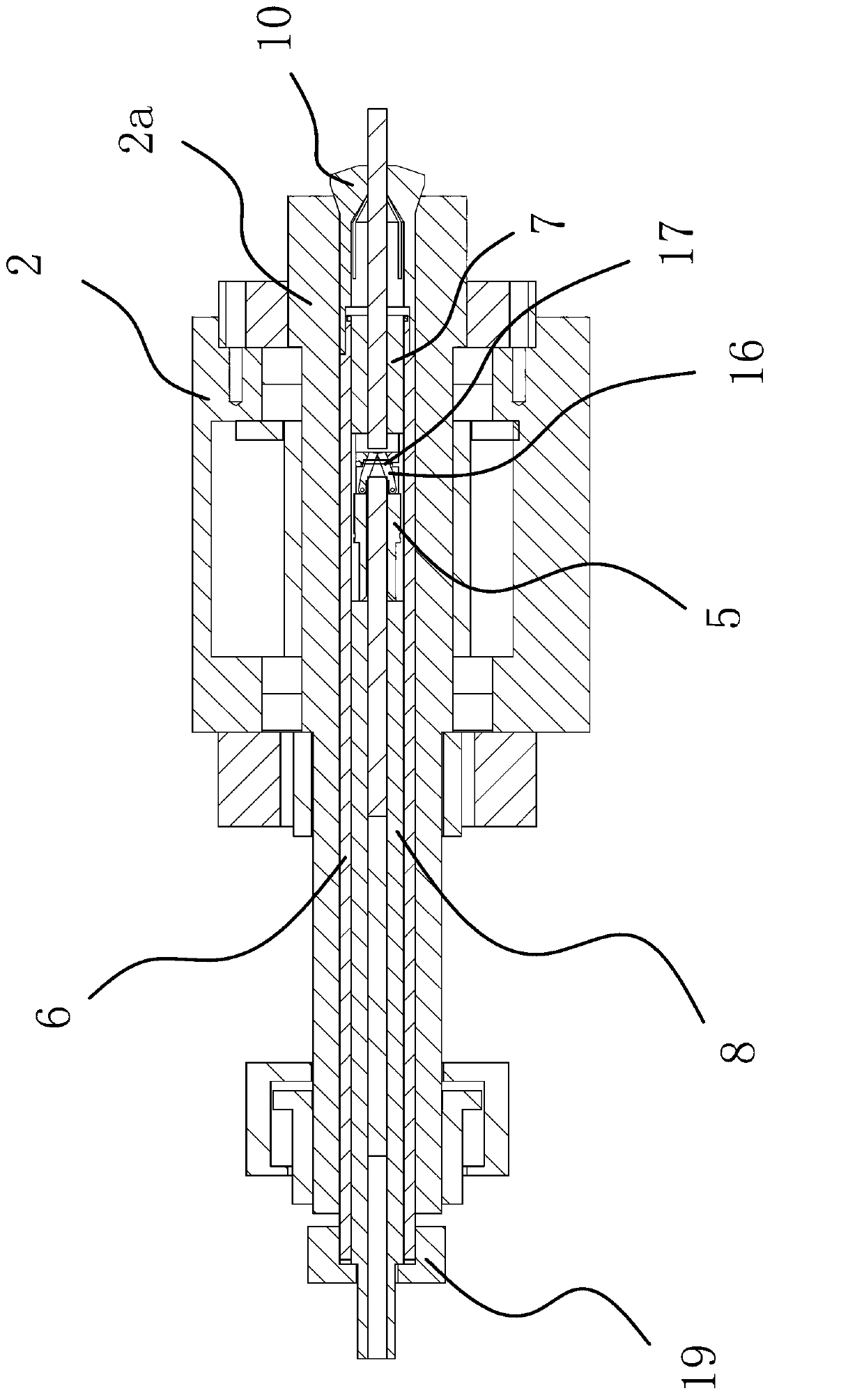

The invention provides a full-automatic numerically-controlled machine tool for shafts, and belongs to the technical field of machinery. The full-automatic numerically-controlled machine tool for the shafts solves the problems that an existing numerically-controlled machine tool for the shafts is low in efficiency because feeding is low in speed, and feeding and blanking are separately carried out. The full-automatic numerically-controlled machine tool for the shafts comprises a working platform, a main machine, a front rack and a rear rack, wherein a material box is installed on the upper side portion of the front rack, a material conveying channel is formed in the front rack, a feeding device is installed on the front rack, a material receiving device is installed on the rear rack, a clamping stay tube is arranged in a spindle, a collet is installed at the front end of the clamping stay tube, a material leading base is installed on the working platform, a double-arm mechanical claw is arranged on the material leading base, a material leading device is arranged between the material leading base and the material receiving device, the material leading device and the spindle are arranged on the same axis line, a locating base is installed in the clamping stay tube, a locating mechanism is installed in the locating base, and a shaft arranged in the locating base can only pass through the locating mechanism under the action of external force. The full-automatic numerically-controlled machine tool for the shafts has the advantages that working efficiency is high, location is accurate, and feeding and blanking are synchronously carried out.

Owner:宁波宫铁智能科技有限公司

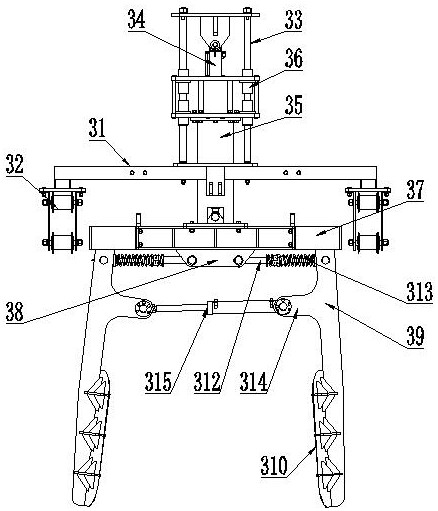

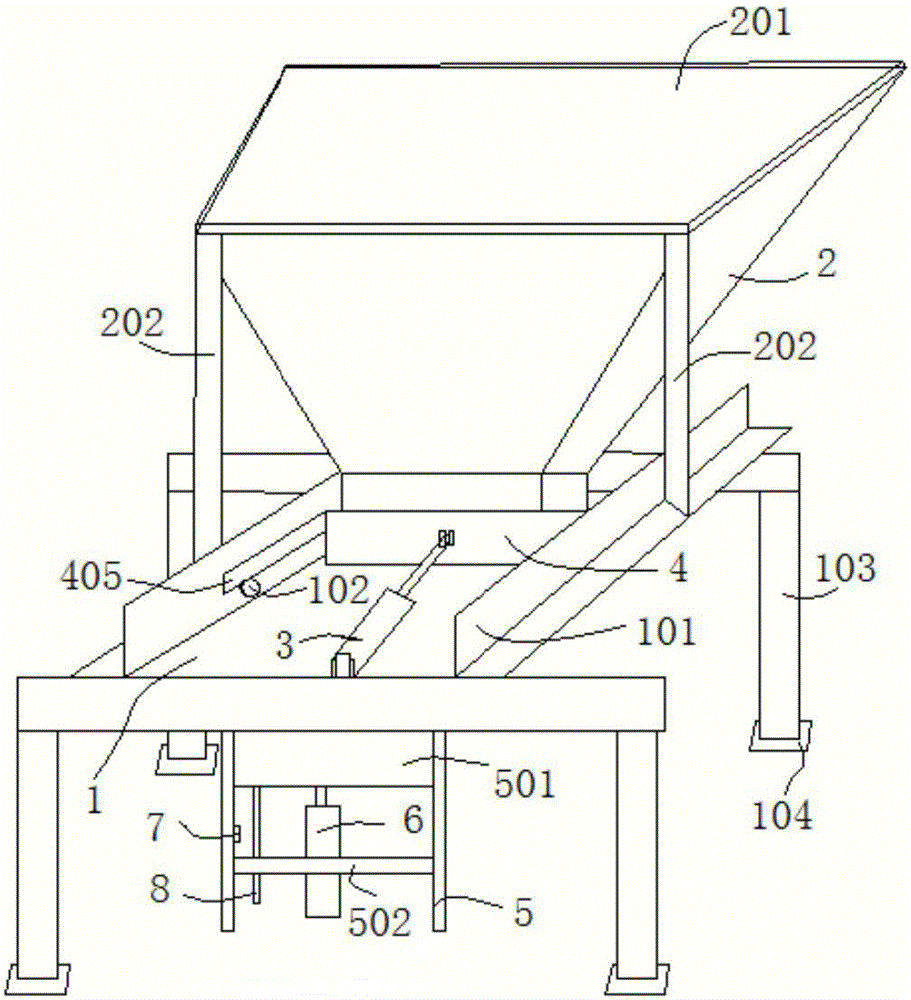

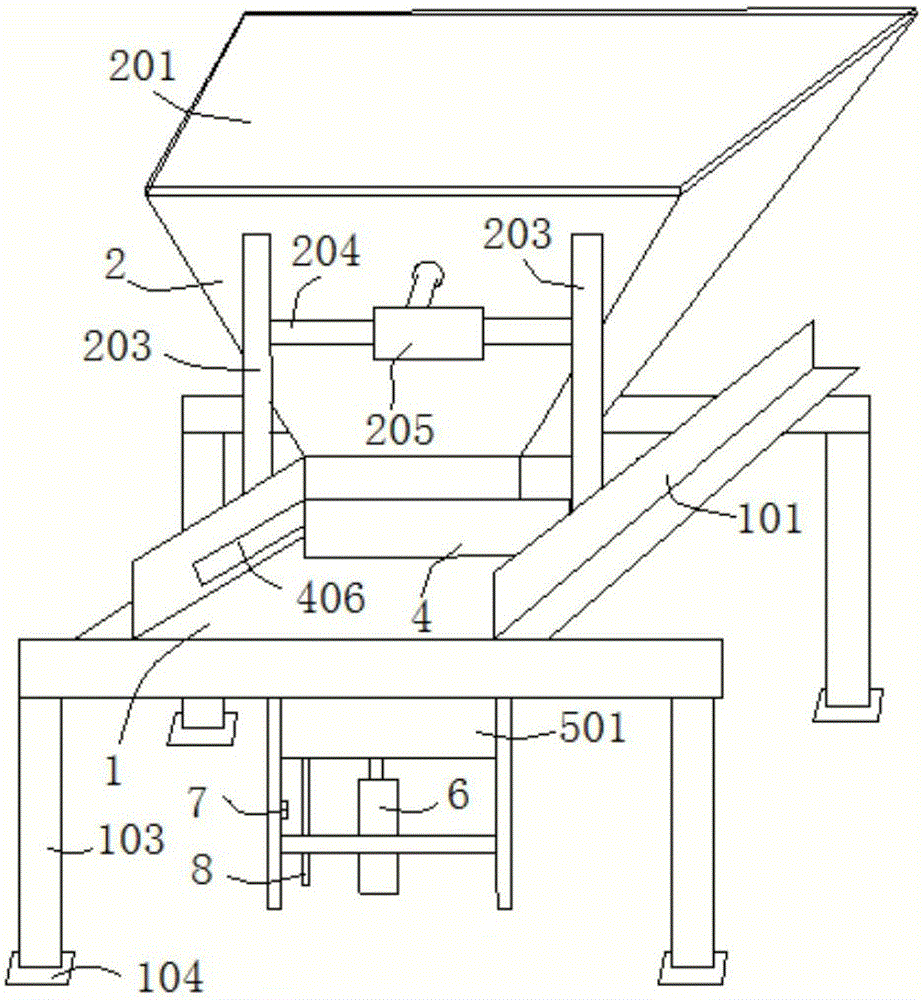

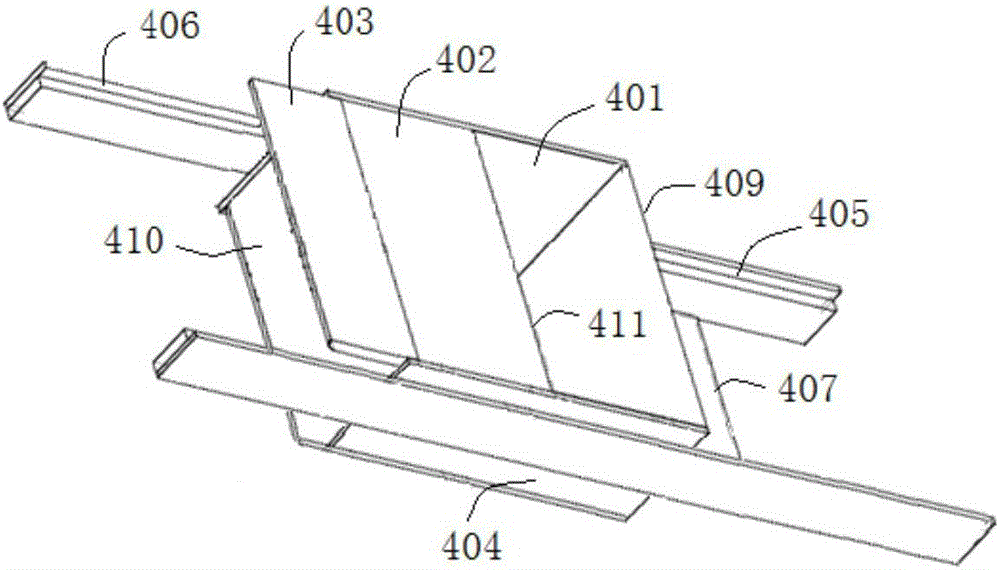

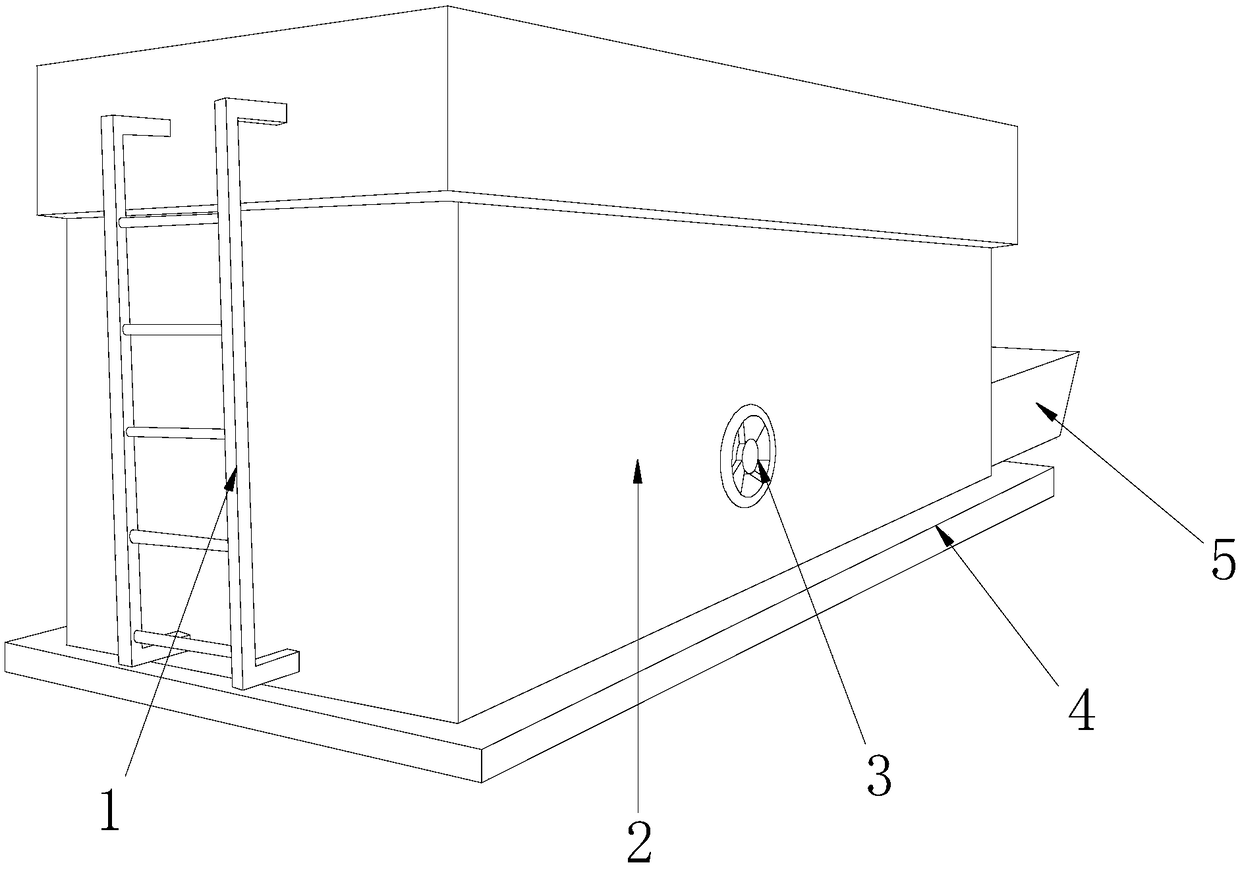

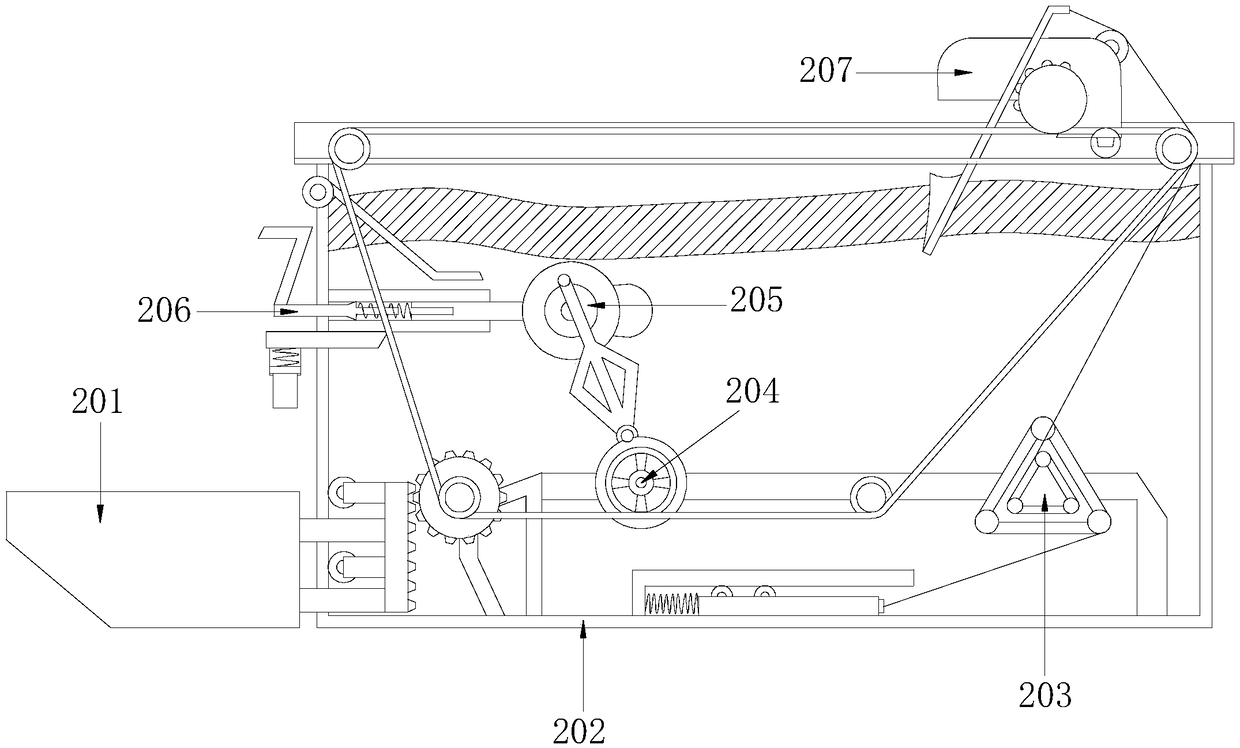

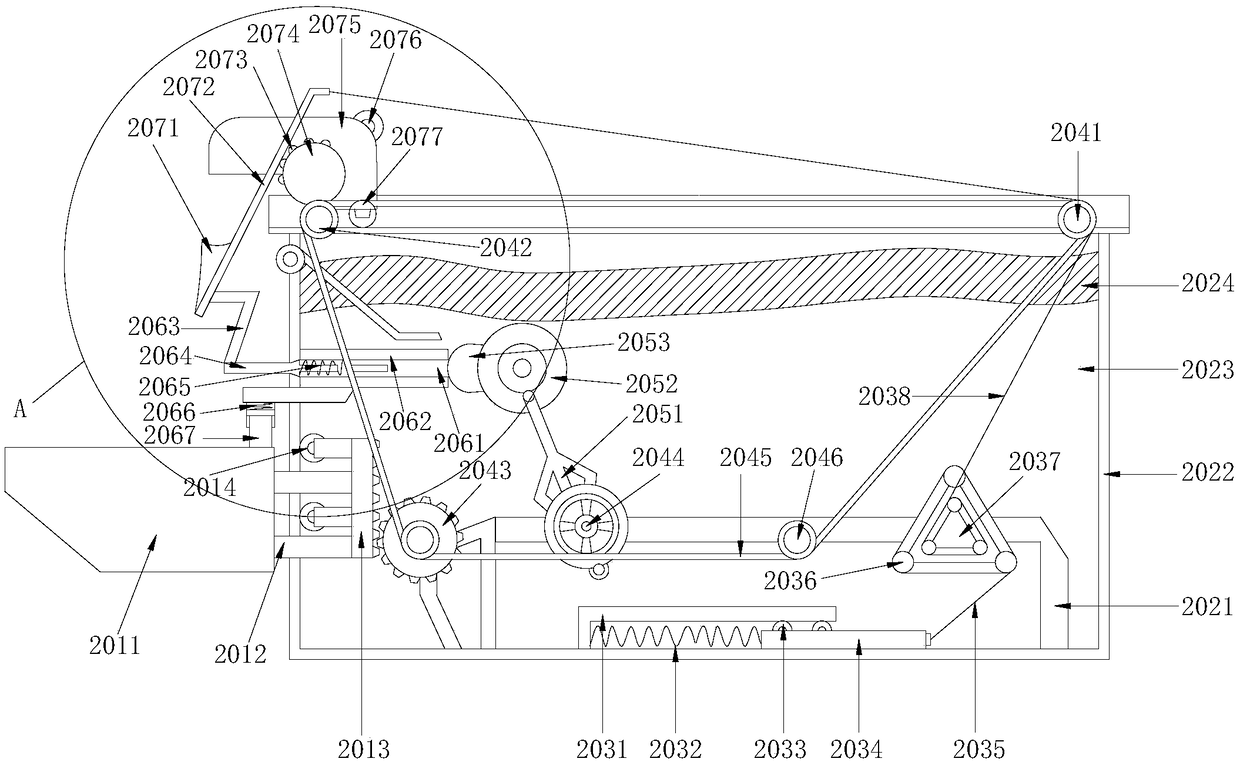

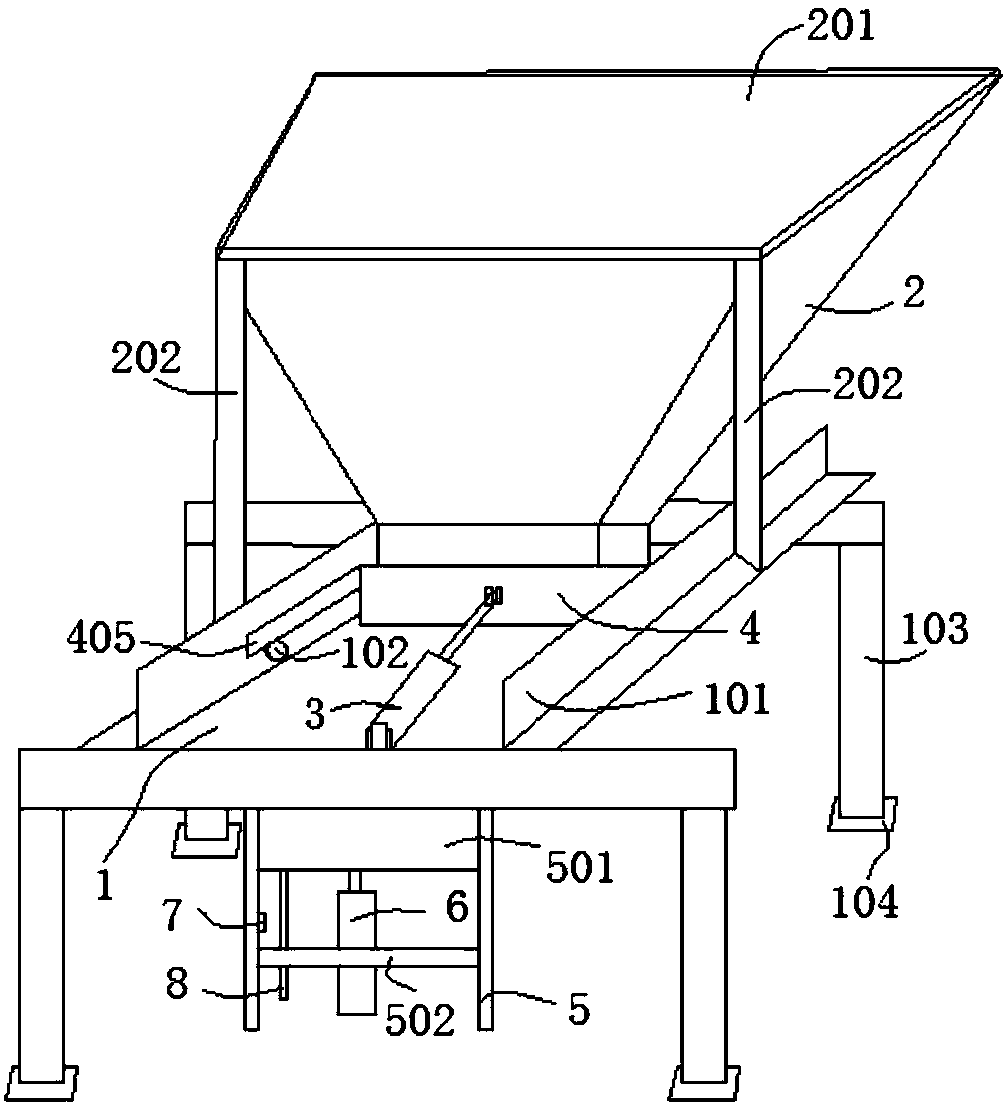

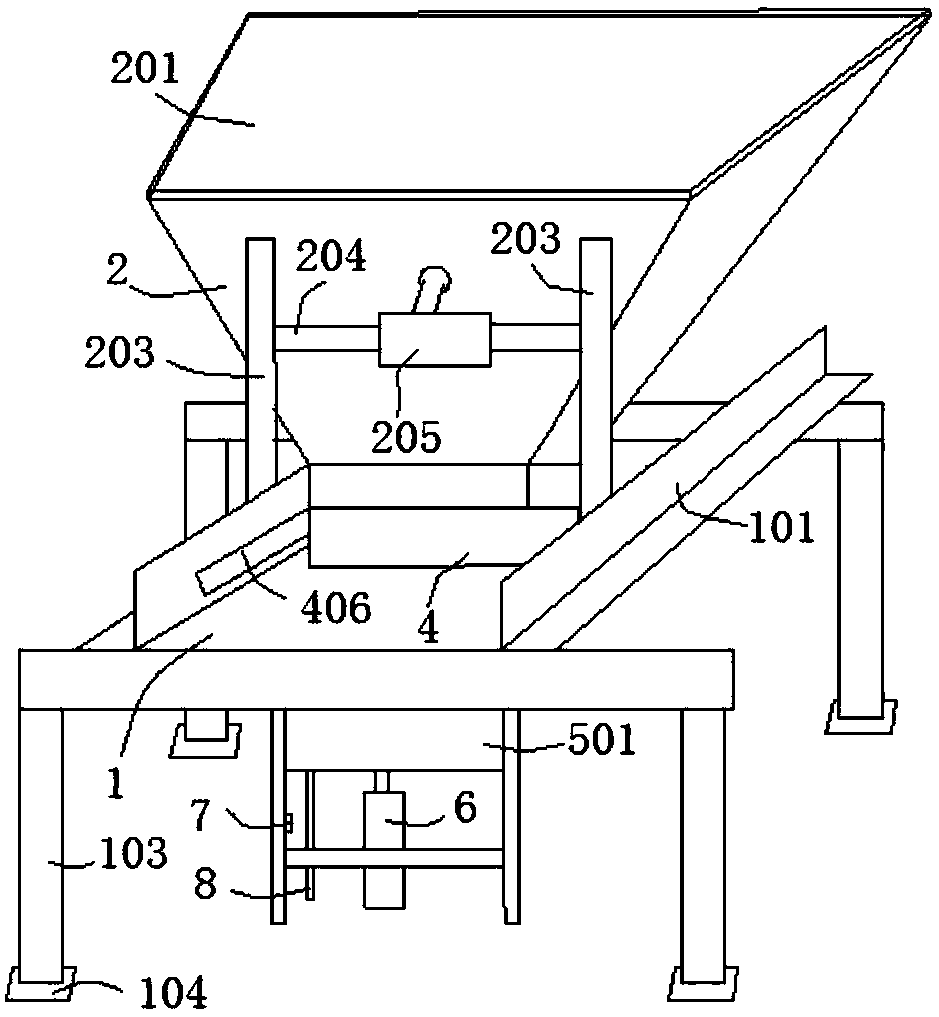

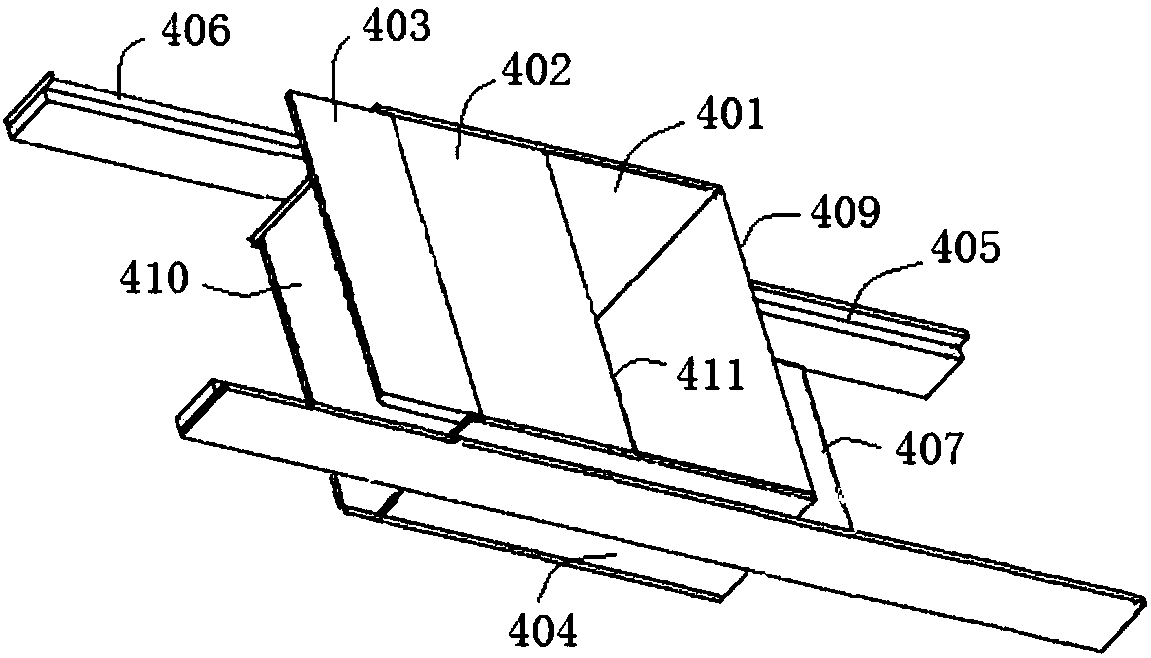

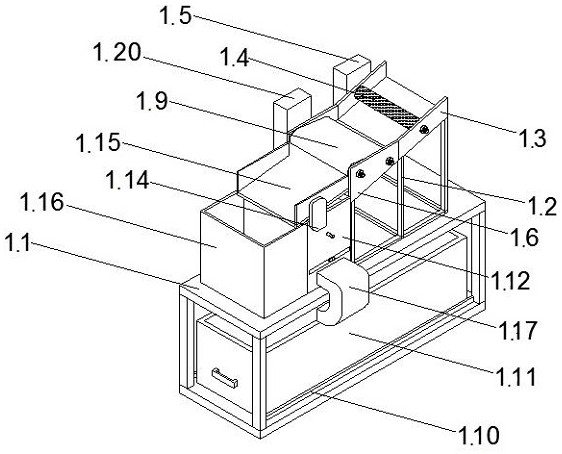

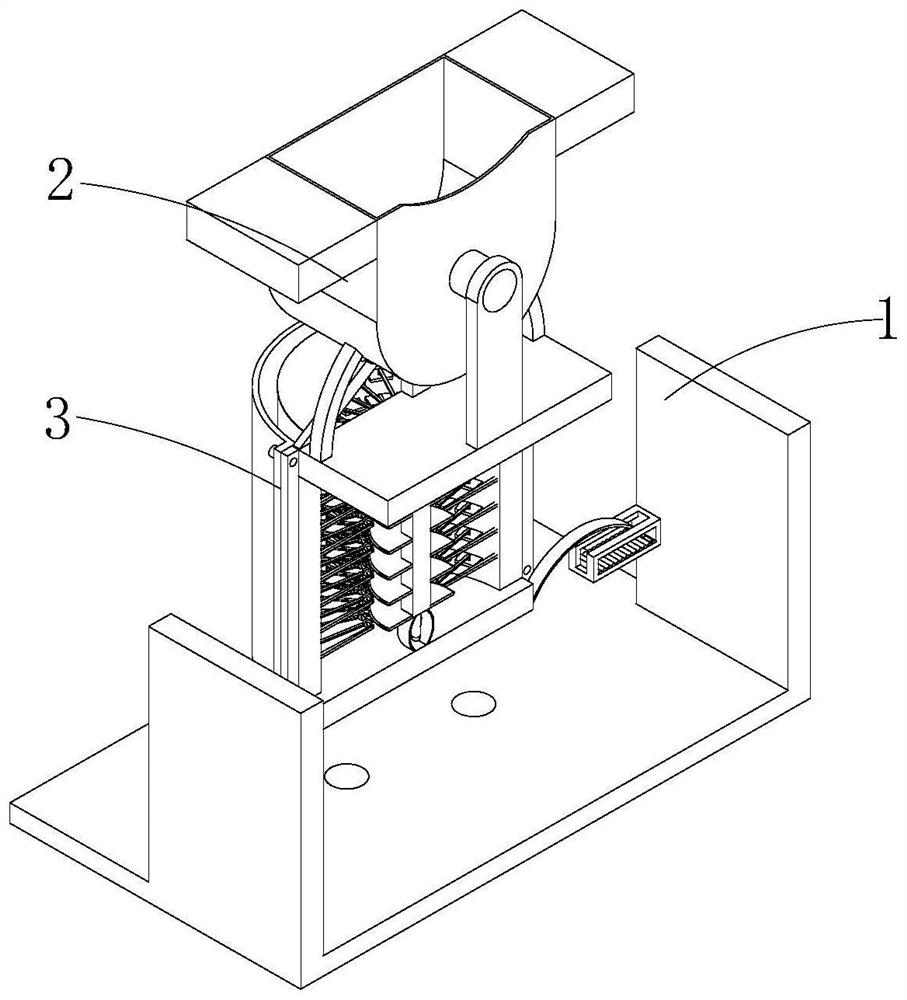

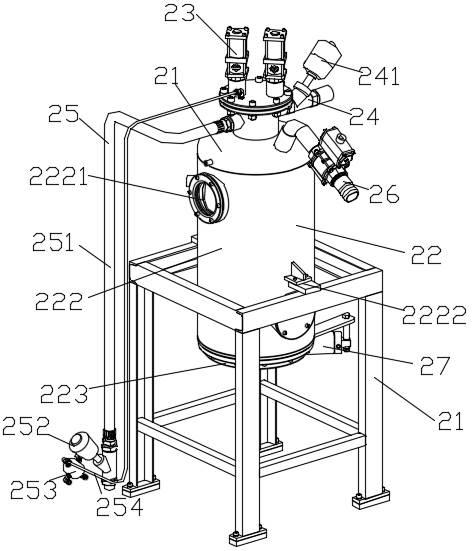

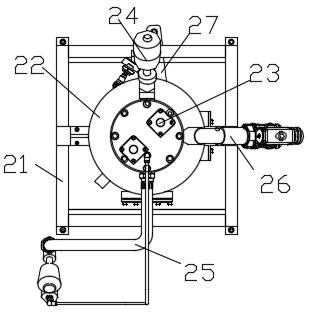

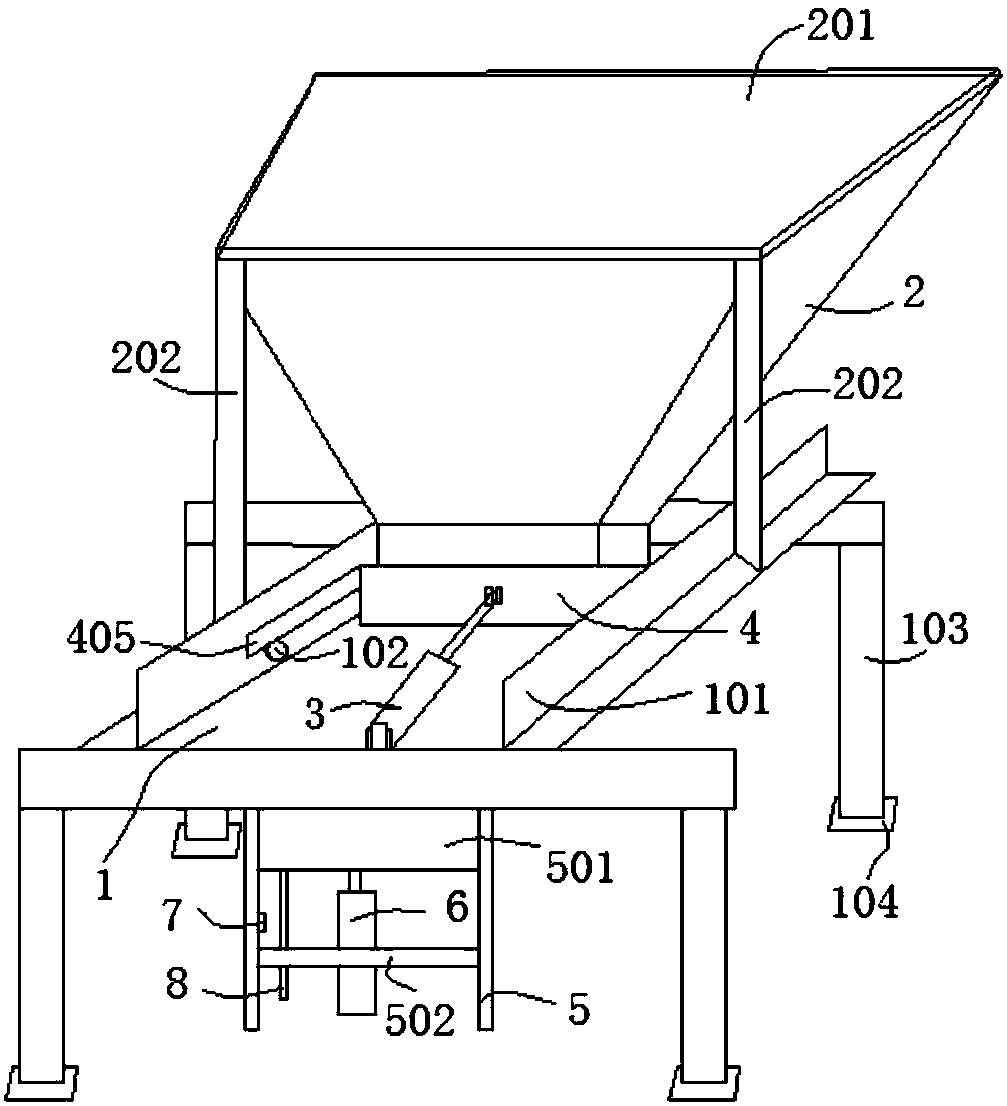

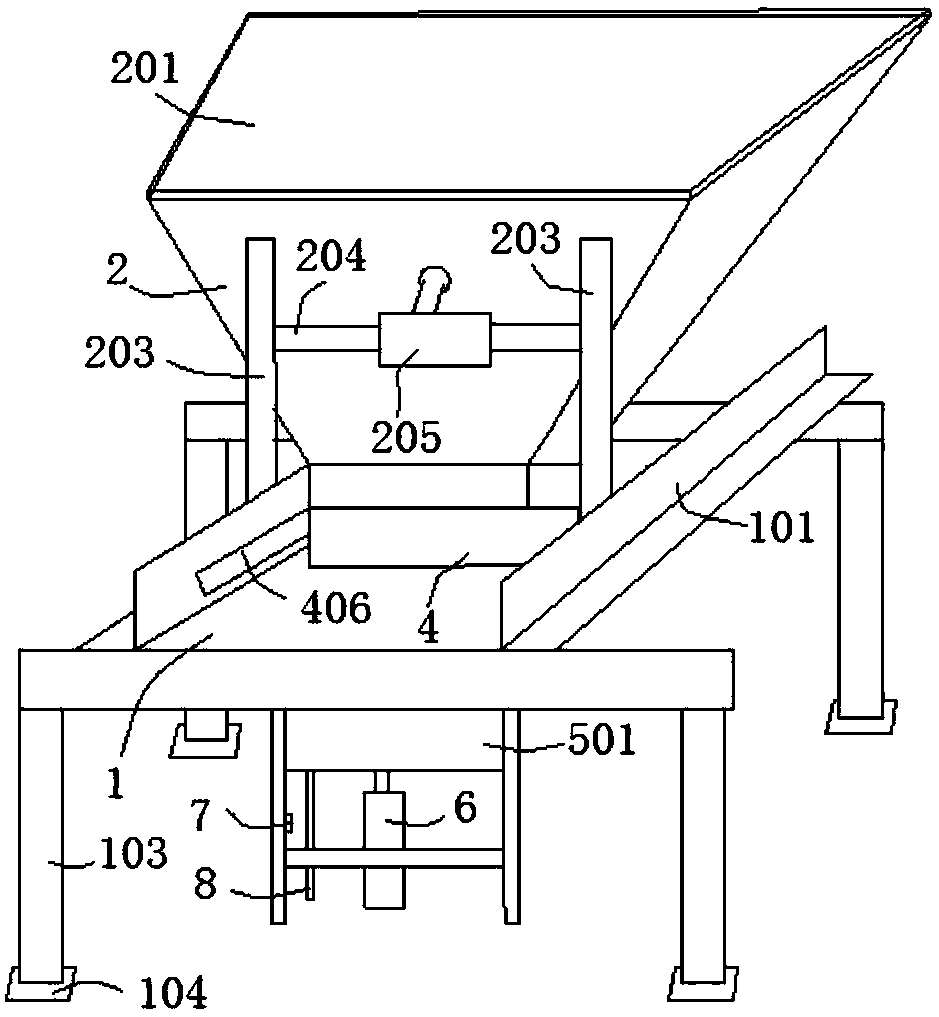

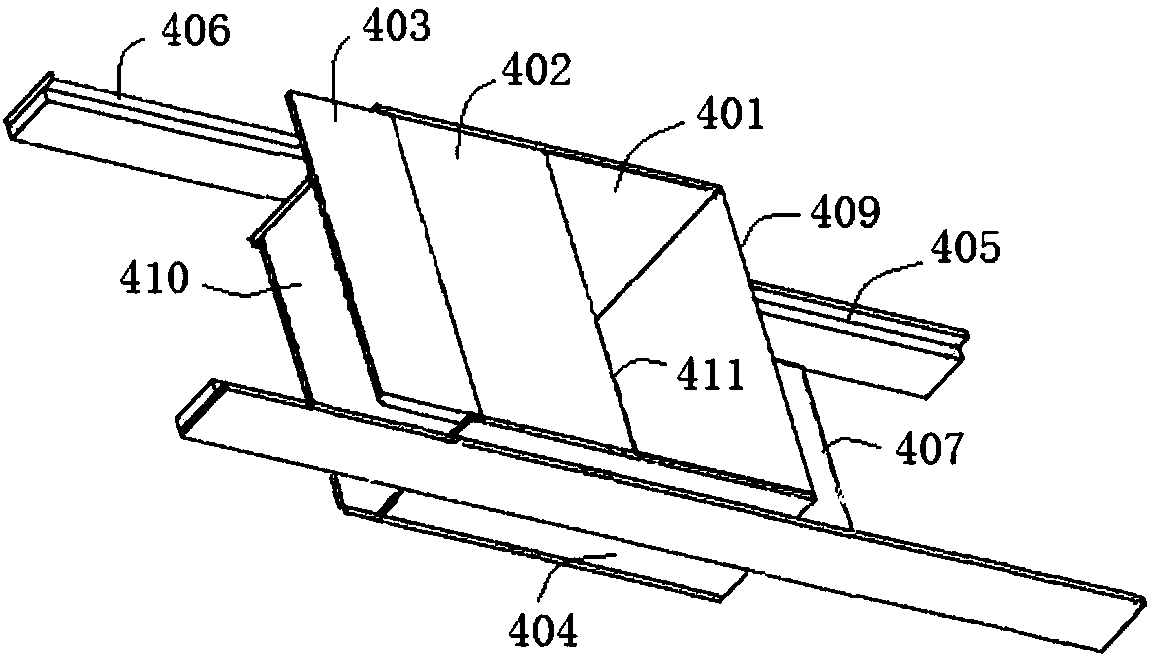

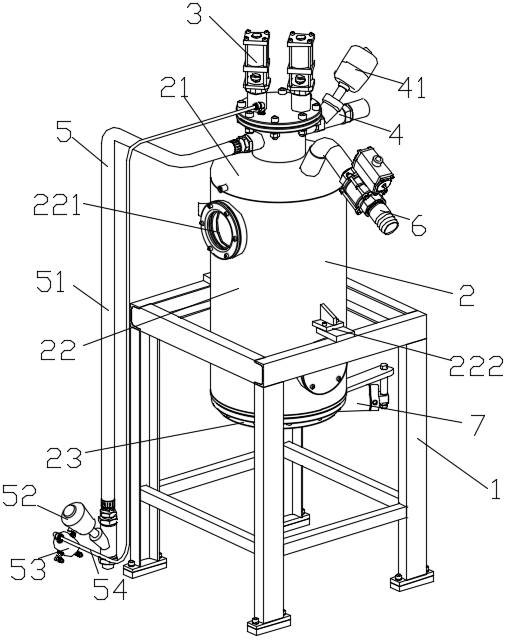

Automatic ton bag breaking system

PendingCN111846487AFully automatedReduce manual involvementConveyorsBags openingStructural engineeringMechanical engineering

The invention discloses an automatic ton bag breaking system. The automatic ton bag breaking system comprises a frame mechanism, wherein a conveying mechanism for conveying ton bags is mounted at oneend of the frame mechanism; a gripper mechanism for lifting and translating the ton bags is mounted at the top of the conveying tail end of the conveying mechanism; the gripper mechanism is driven bya gripper pushing mechanism; a bag breaking mechanism for breaking the ton bags is arranged under the moving tail end of the gripper mechanism; a ton bag buffering mechanism and a ton bag beating structure are arranged obliquely above the bag breaking mechanism; and a waste bag clamping mechanism is arranged on one side of the ton bag beating structure. The automatic ton bag breaking system can realize full automation of the processes of conveying the ton bags, breaking the bags and taking waste bags, and reduces the labor cost; the stability of the lifting and translating processes of the tonbags is ensured, instability of the ton bags is avoided, and the situation that the bag breaking positions are different due to deviation of bag bodies is avoided; and the automatic ton bag breakingsystem is quick in bag breaking, good in effect and quick in material unloading, and can ensure one-time bag breaking of the ton bags.

Owner:ANQIU BOYANG MACHINERY MFR

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Temperature control falling system

ActiveCN105757680AMove fastMovement speed adjustmentIncinerator apparatusTemperature controlCombustion

The invention discloses a temperature control falling system which comprises a combustion cavity, a detection device, a falling device and a control device, wherein temperature distribution situation is preset in the control device; the temperature distribution situation inside the combustion cavity can be acquired by the control device through the detection device; at least one group of first height-temperature information is extracted; the first height-temperature information comprise heights and temperatures corresponding to the heights; at least one group of second height-temperature information is extracted from the preset temperature distribution situation; the second height-temperature information comprises heights and temperatures corresponding to the heights; the heights in the second height-temperature information equal to those in the first height-temperature information; a temperature difference T is calculated by the control device by comparing the first height-temperature information with the second first height-temperature information; the falling device is controlled by the control device to work according to the temperature difference T.

Owner:湖南未名环保科技有限公司

Centralized removal device for floating sludge residues in sewage treatment tank

InactiveCN109173357AImprove removal efficiencyImprove cleaning efficiencySettling tanks feed/dischargeSedimentation settling tanksTreatment pondSludge

The invention discloses a centralized removal device for floating sludge residues in a sewage treatment tank. The centralized removal device structurally comprises an observation ladder, a treatment tank, a sludge scrapping hand wheel, a fixed bottom plate and a floating sludge collecting device. The treatment tank of the centralized removal device is required to be subjected to floating sludge removal, the sludge scraping hand wheel can be directly rotated by working personnel, then, a driving mechanism is driven to push a sludge scrapping mechanism towards the left end of a main body, then,the sludge scrapping mechanism is dragged by an assisting mechanism to successfully upwarp, furthermore, a floating sludge layer is removed and is poured into a collecting box, in addition, a main transmission mechanism is driven by the driving mechanism to control a dithering mechanism to generation vibration to ensure that floating sludge in the sludge scrapping mechanism is successfully pouredinto a box body, so that the floating sludge removal efficiency is effectively increased, and the cleaning efficiency is increased; and it is unnecessary that the working personnel climb to the upperend of the treatment tank to control the treatment tank, so that the risk and manpower are greatly reduced.

Owner:林锋忠

Temperature control falling system

The invention discloses a temperature control falling system which comprises a combustion cavity, a detection device, a falling device and a control device, wherein n temperature differences t1, t2,...and tn are preset in the control device; any preset temperature difference ti corresponds to two heights hi1 and hi2; the temperature distribution situation inside the combustion cavity can be acquired by the control device through the detection device; m preset temperature differences are selected by the control device; heights hj1 and hj2 corresponding to any preset temperature difference tj of the m preset temperature differences are obtained; according to the temperature distribution situation inside the combustion cavity, a practical temperature difference Tj of the heights hj1 and hj2 is obtained; the difference X of the preset temperature difference tj and the practical temperature difference Tj is obtained through calculation of the control device; the falling device is controlled by the control device to work according to the difference X.

Owner:湖南未名环保科技有限公司

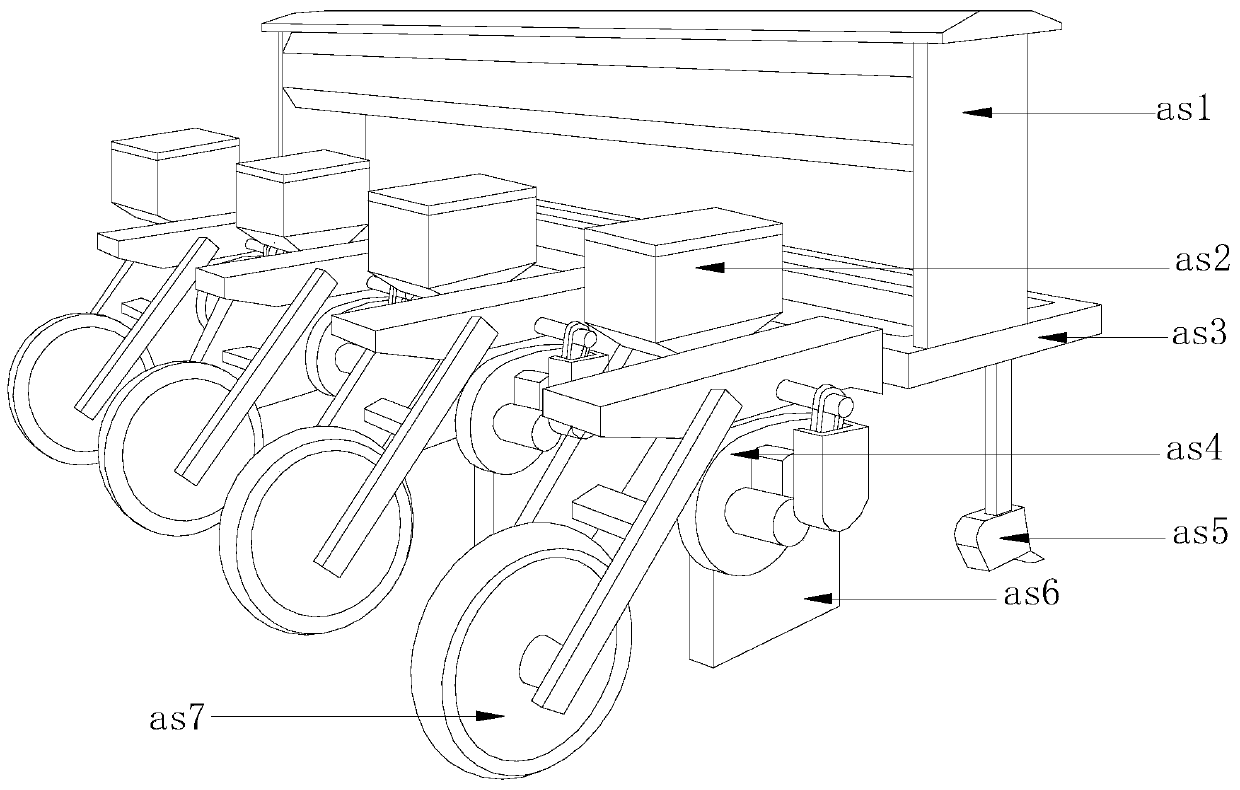

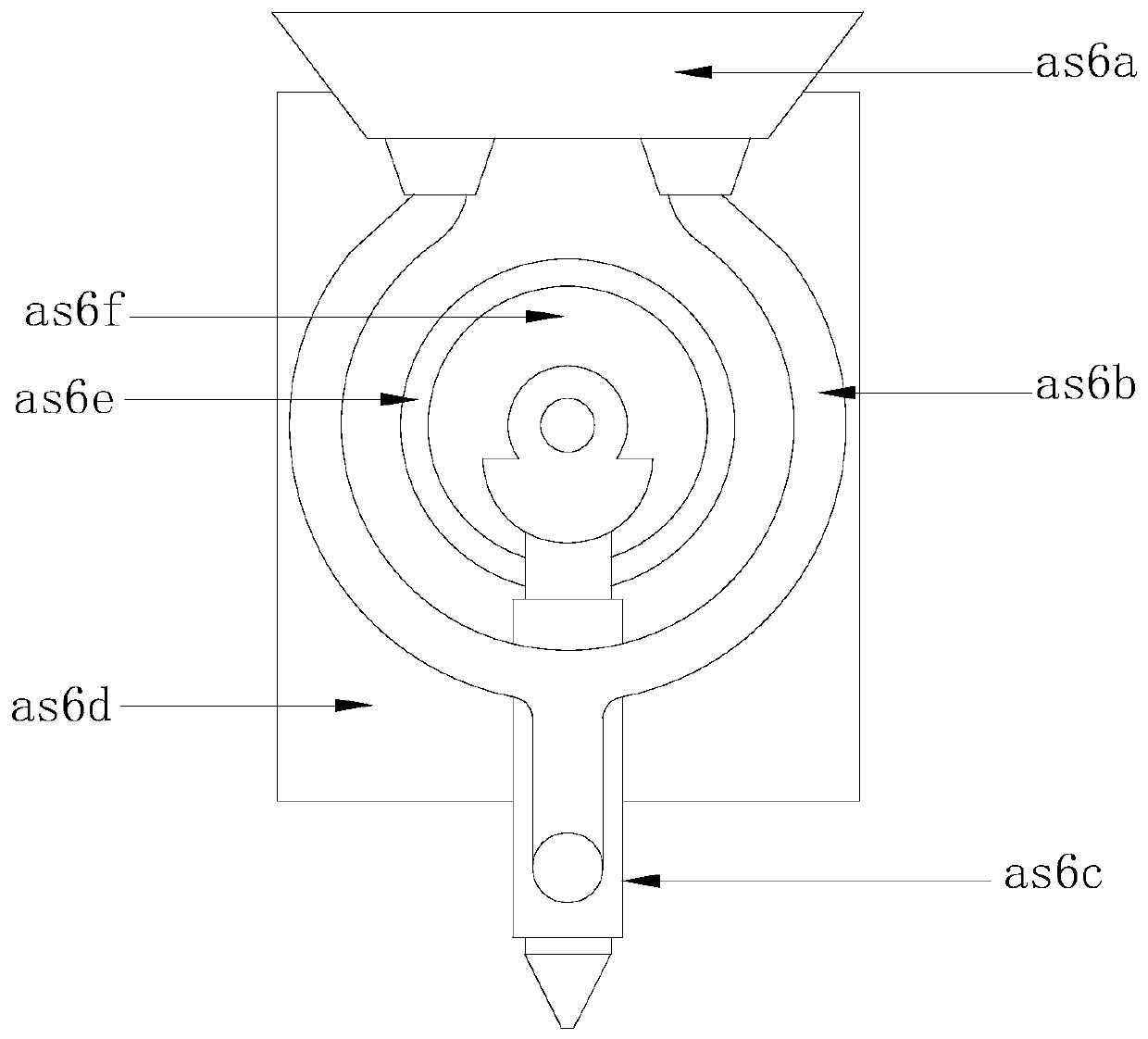

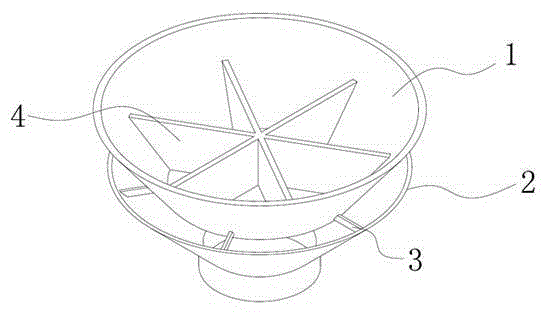

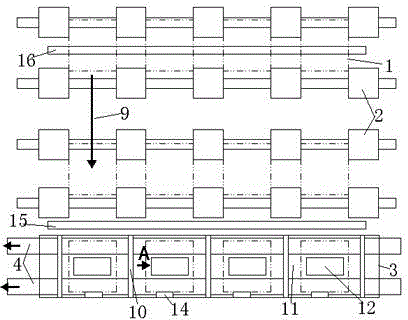

Combined precision seeder based on principle of built-in feeding

The invention discloses a combined precision seeder based on the principle of built-in feeding. The combined precision seeder structurally comprises a main assembly body, storage boxes, a fixed frame,four drive motors, looseners, a sowing mechanism and driving wheels; rear ends of the drive motors are uniformly and equally distributed at the front end of the fixed frame. In order to prevent blockage, four material separation pipes respectively guide seeds in a material separation port into a material distribution mechanism, a feeding shaft in the material distribution mechanism is used for quantitative packing and is pushed down through a protruding push pin, a built-in rotating rod is in the static state in rotation, seeds are pushed out through a top-rotating cone head and are sown laterally to avoid accumulation in the soil, shaking of a shake-out mechanism can greatly increase the falling speed of the seeds, the whole use can guaranteed the accurate quantitative sowing, the position of the seeds is decentralized, the absorption of nutrients is greatly improved, and the impact on growth is prevented.

Owner:吴美珠

A processing method for extruding unburned bricks

ActiveCN106626003BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

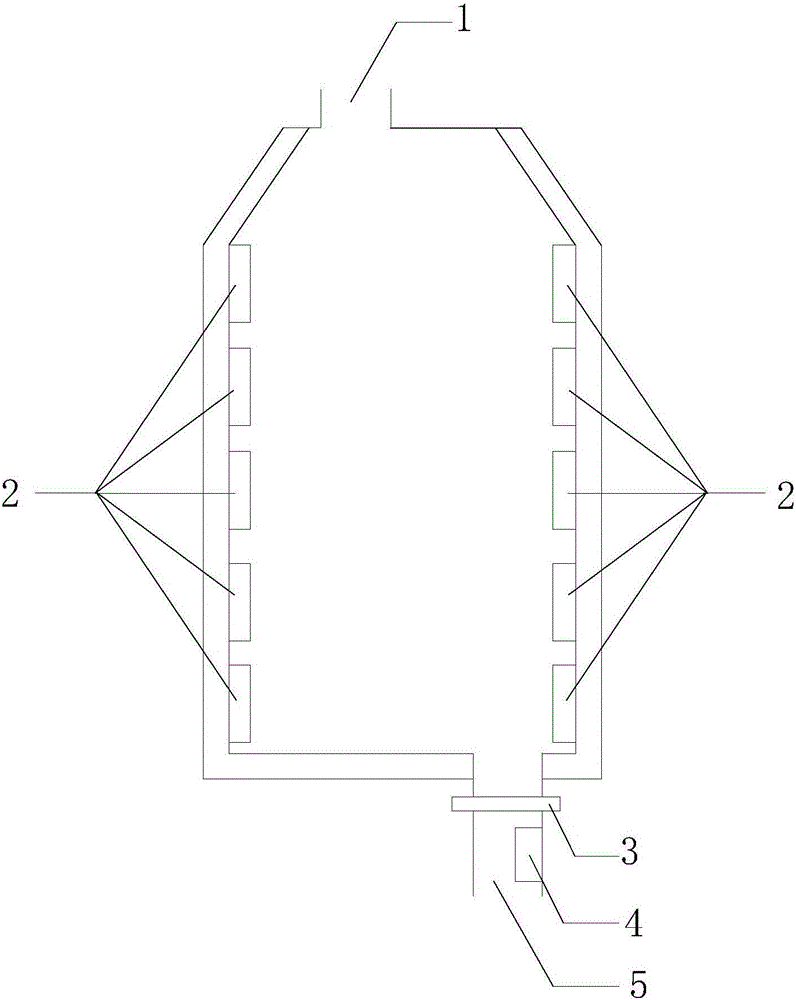

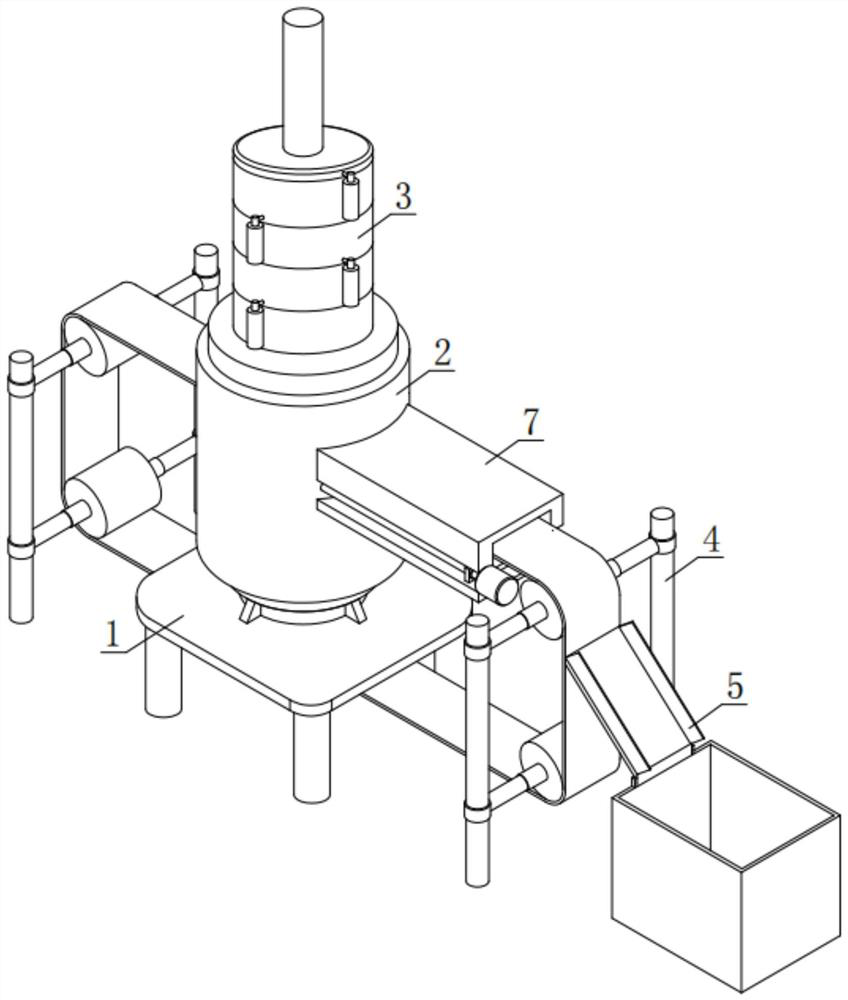

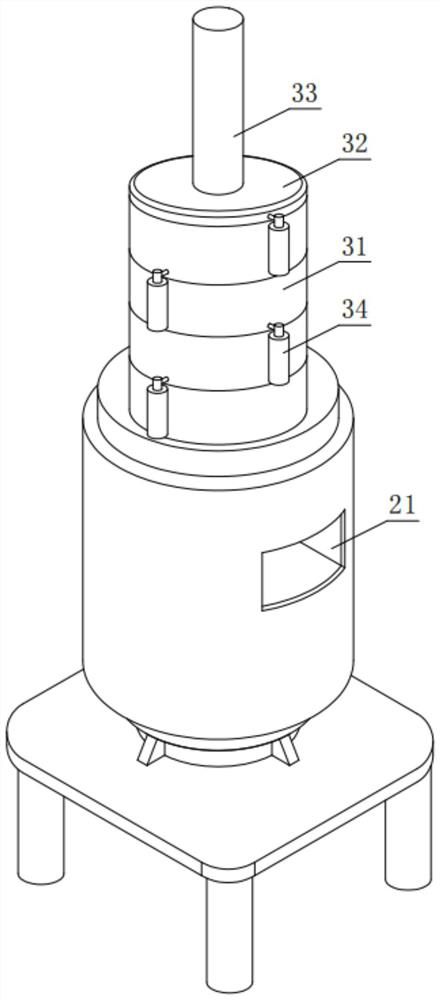

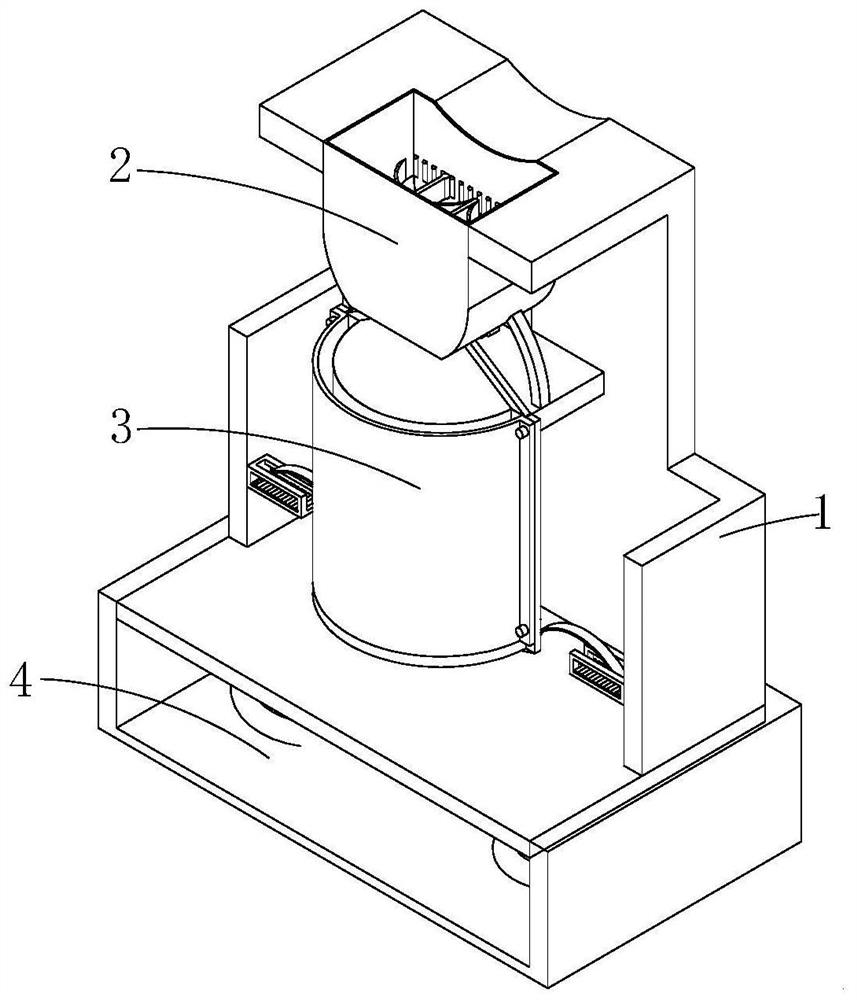

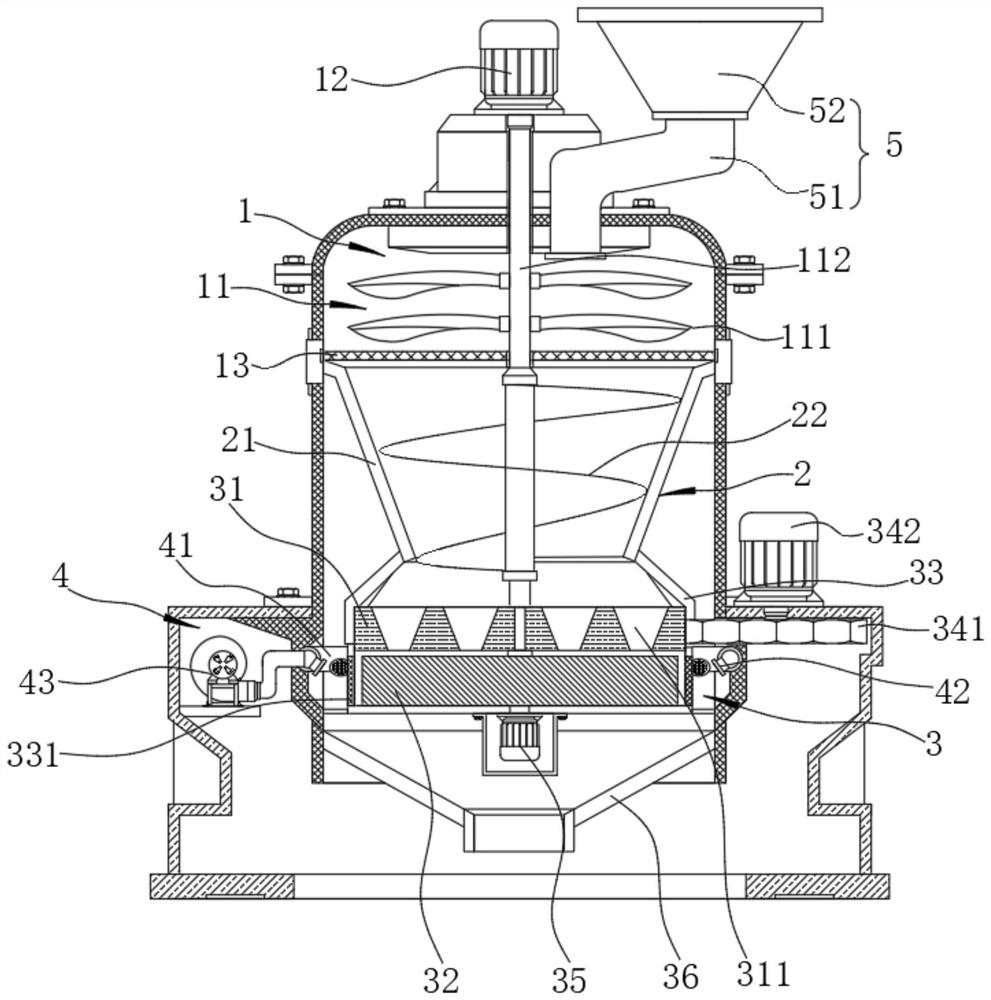

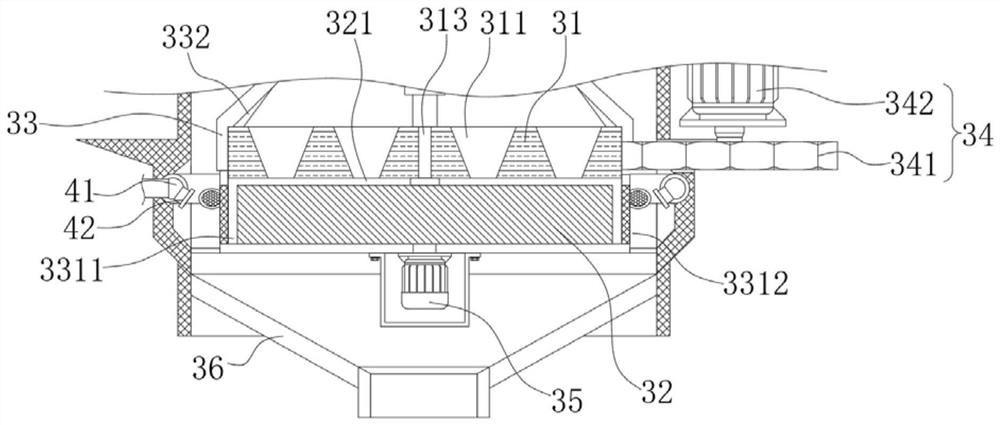

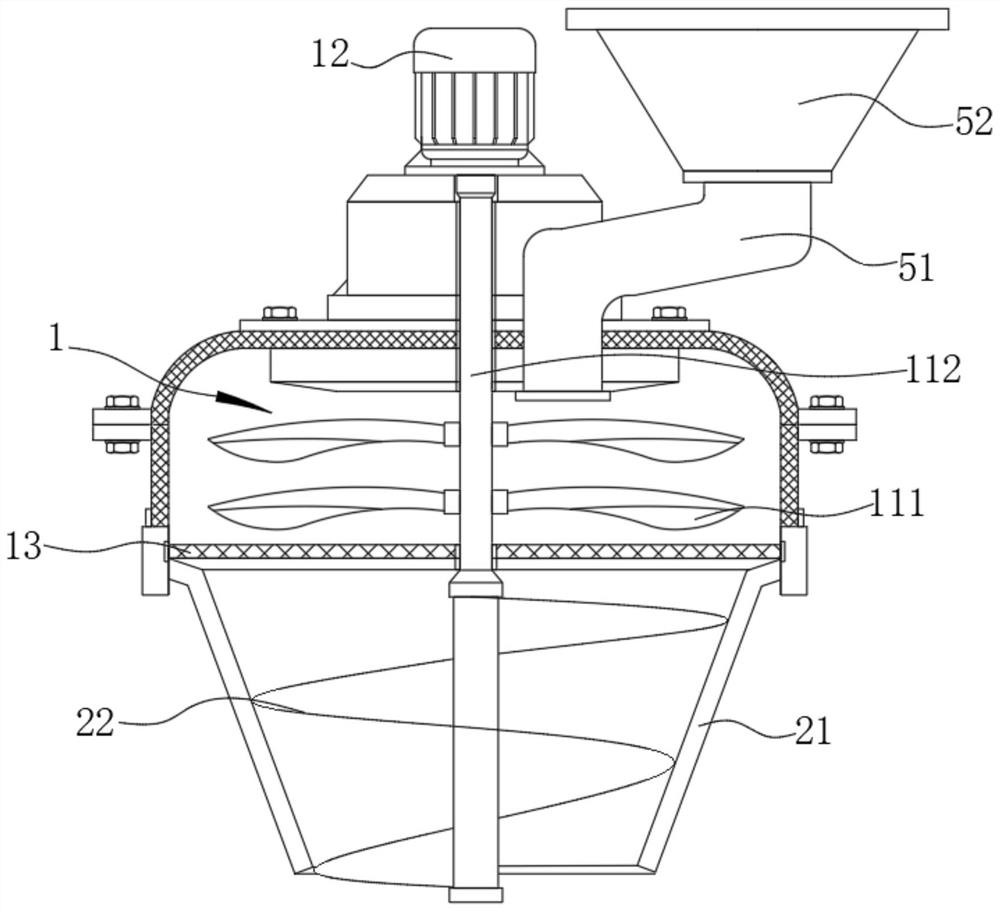

Recycled concrete waste recovery device

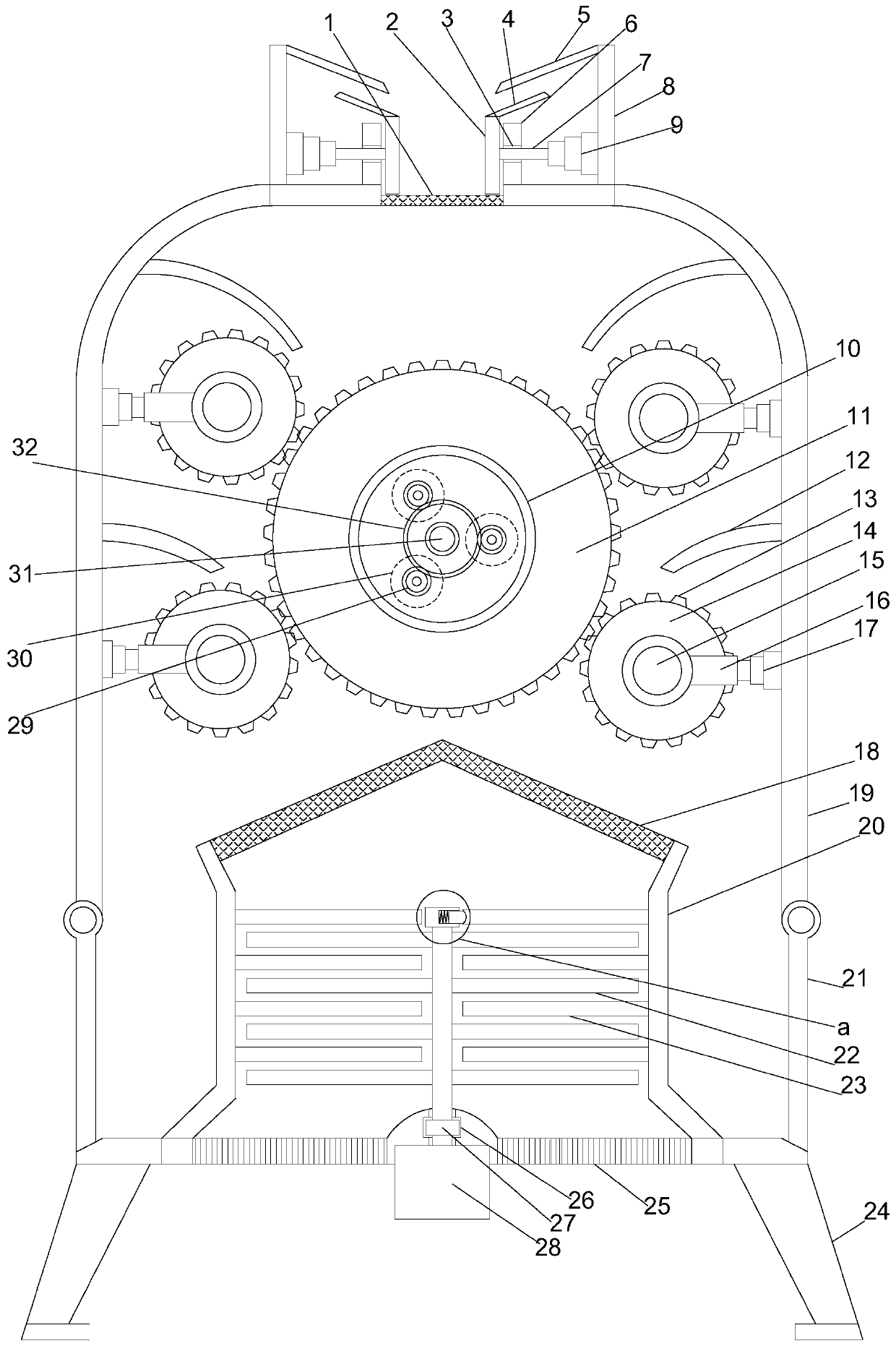

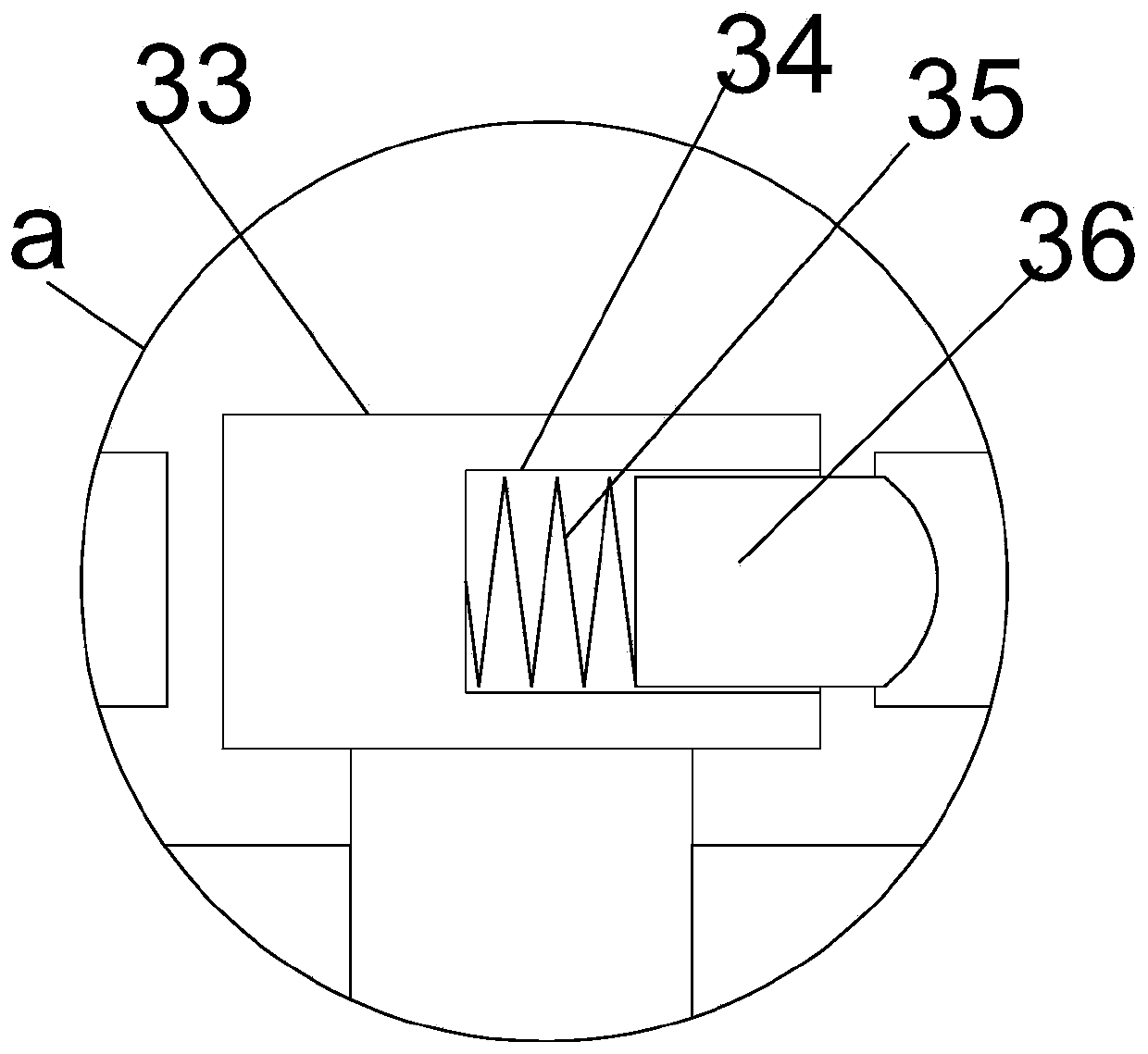

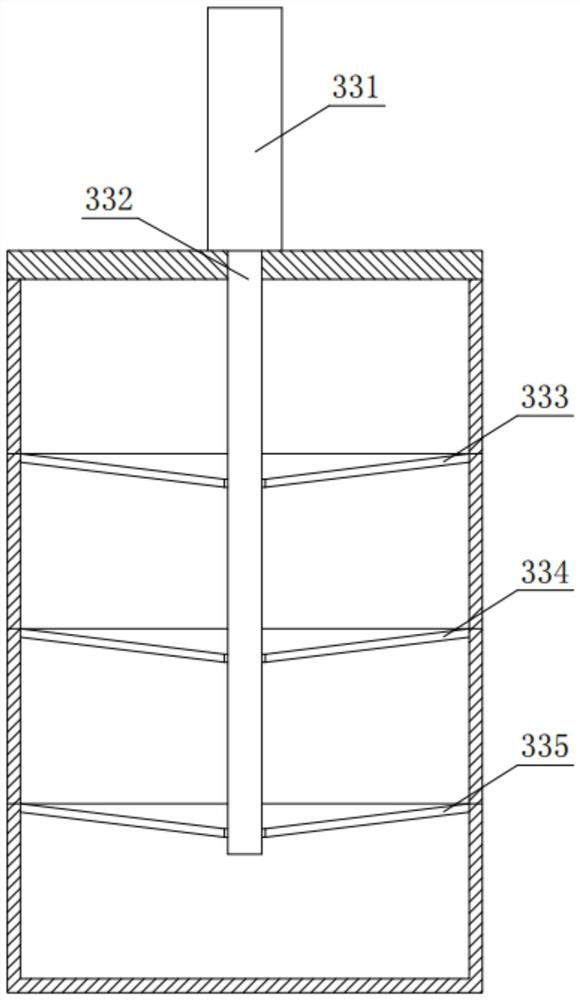

InactiveCN111468271AImprove crushing efficiencyImprove crushing qualityGrain treatmentsWaste materialWaste recovery

The invention relates to the field of concrete recovery, in particular to a recycled concrete waste recovery device. The recycled concrete waste recovery device comprises a vertically-arranged supporting mounting barrel. Multiple supporting mounting columns are arranged at the lower end of the supporting mounting barrel by the equal angle. A feeding mounting barrel is vertically arranged at the middle position of the upper end of the supporting mounting barrel. A crushing and guiding barrel is vertically arranged at the middle position of the bottom of the supporting mounting barrel. Multipledischarging gates are arranged at the position, corresponding to the crushing and guiding barrel, of the wall of the supporting mounting barrel by the equal angle. A guiding mounting barrel is vertically arranged at the middle position of the feeding mounting barrel. Through multi-stage crushing and screening, the crushing efficiency and quality of recycled concrete are improved remarkably, the crushing precision is adjusted through clearance adjusting, impurities are guided out during crushing and screening, the recovery quality of recycled concrete is improved, the material falling speed ofthe device is obviously increased in cooperation with vibration generated by rotating, and the recovery efficiency of the device is improved.

Owner:新沂市瑞阳混凝土工程有限公司

Halogen-free flame-retardant PBT material and preparation process thereof

PendingCN112724616AHigh CTI valueGood physical propertiesHollow article cleaningPolytetramethylene terephthalateGlass fiber

The invention relates to a halogen-free flame-retardant PBT material and a preparation process thereof. The halogen-free flame-retardant PBT material is prepared from the following six components in percentage by weight: polybutylene terephthalate, halogen-free flame retardant, antioxidant, compatilizer, silicate and glass fiber. The percentage of the content of the six components is as follows: 50-70% of polybutylene terephthalate; 18%-25% of the halogen-free flame retardant; 0.5%-1% of the antioxidant; 1%-5% of the compatilizer; 0.5%-1% of silicate; 0-30% of glass fiber. According to the halogen-free flame-retardant PBT material and the preparation process thereof, through reasonable improvement of a production line, waste is avoided, the raw material utilization rate is higher, and the product performance is better.

Owner:JIANGYIN JIHUA NEW MATERIAL

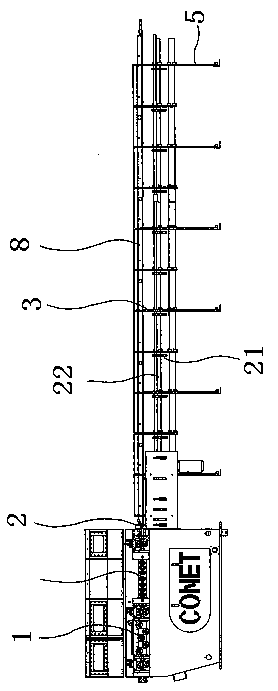

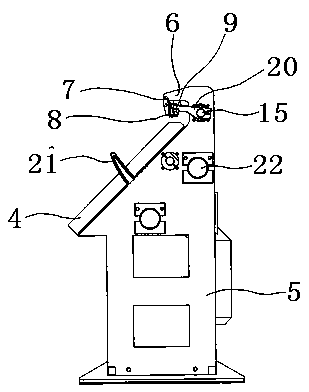

Special steel bar feeding machine used during electric pole reinforcement cage preparing

The invention discloses a special steel bar feeder used in the preparation of steel bar cages for electric poles. One end of the material rack is fixedly connected to the second feed rack, and supports are fixedly connected to both sides of the top of the base, and the top of the base is fixedly connected to a material distribution motor at the position on the left side of the support through a fixed seat, and the output of the material distribution motor is One end of the shaft is fixedly connected with a connecting shaft. The end of the connecting shaft away from the material distribution motor runs through the bracket and extends to the inside of the bracket. The end of the connecting shaft extending to the inside of the bracket is rotatably connected with the bracket. The invention relates to steel cage manufacturing technology field. It solves the problems that the existing steel bar feeder has large volume, low feeding speed, easy material jam, low efficiency of steel cage preparation, waste of manpower and the like.

Owner:泰州市春为强通用机械有限公司

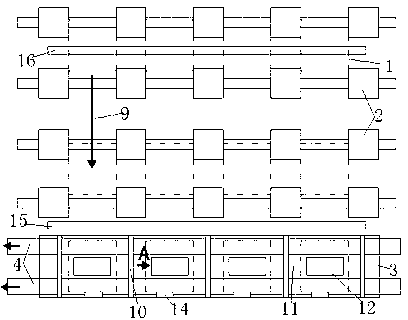

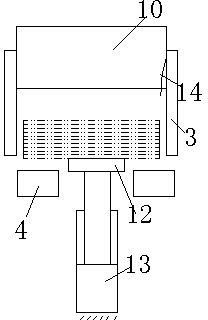

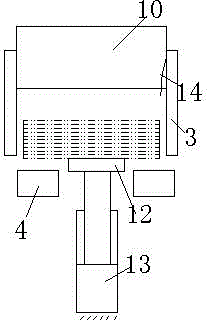

Mechanical arm collective blanking device

ActiveCN103253541AIncrease the blanking speedSimple structurePile receiversArticle deliveryRobotic armEngineering

Owner:FUJIAN FUZHEN METAL PACKING CO LTD

Marine waste treatment device

The invention relates to the field of marine devices, in particular to a marine waste treatment device. The device comprises a horizontally arranged support mounting plate. The upper end of the support mounting plate is vertically provided with a support mounting tube. The upper right half of the support mounting tube extends vertically and is provided with a conical surface feeding cylinder. Theinner part of the conical surface feeding cylinder is horizontally provided with a passive rotating mounting feeding structure. The inner upper half of the support mounting tube is horizontally provided with a filter material crushing structure. The inner lower half of the support mounting tube is provided with a guide material storage structure. The condition that feeding and crushing do not affect each other is realized through rotation and resetting, and cleanliness and safety of a work area is ensured. The dislocation crushing and interchangeable replacement of filter plates make crushingrapid and more adaptable. The high-speed rotation of an eccentric vibrating wheel makes the entire device vibrate, and greatly increases the speed of blanking. The closed fermentation greatly improvesthe utilization rate of waste, and has a small environmental impact.

Owner:彭秀真

Steel bar straightening and shearing machine and steel bar straightening and shearing method

The invention belongs to the technical field of a steel bar straightening and shearing machine and a steel bar straightening and shearing method and discloses the steel bar straightening and shearing machine and the steel bar straightening and shearing method. The steel bar straightening and shearing machine and the steel bar straightening and shearing method are mainly technically characterized in that an unloading mechanism comprises frame bodies with discharging inclined plates, lifting hooks are arranged above the frame bodies, the lower ends of the lifting hooks are connected to angle iron through movable chain flaps, and box iron with an opening at the lower end is arranged above a horizontal side of each piece of angle iron; a cutting mechanism comprises a fixing frame, a lower cutter fixed to the lower part, an upper cutter fixing base and an upper cutter located on the upper cutter fixing base, a first rotating shaft is fixed to the fixing frame through a bearing, the upper cutter fixing base is connected to the first rotating shaft through a shaft pin, one end of the first rotating shaft is fixedly connected to the end of the box iron, a swing rod is arranged at the other end of the first rotating shaft, a second rotating shaft is arranged on a frame body and is provided with a rotating connection rod synchronous with the second rotating shaft, the front end of the rotating connection rod is fixedly connected to the upper end of the box iron, and the box iron is movably provided with a connecting plate. According to the invention, the falling speed is increased, and the production efficiency is further improved.

Owner:安志攀

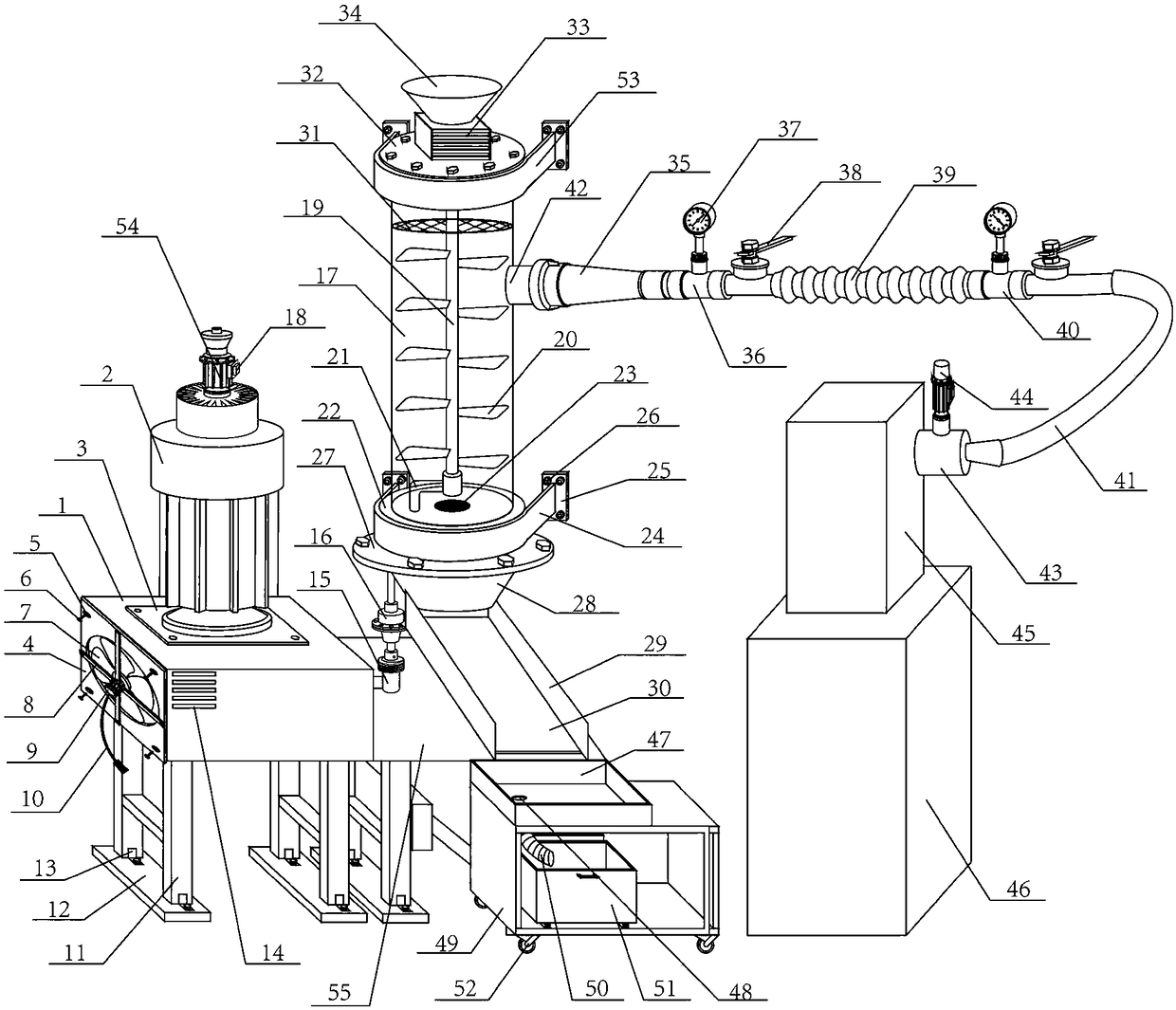

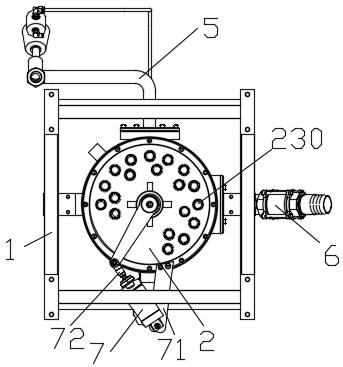

Purification device for production of electronic-grade silica powder and implementation method of purification device

PendingCN114178174AEfficient separationAvoid cloggingSievingSilicaPhysical chemistryElectric machinery

The invention discloses a purification device for electronic-grade silica powder production and an implementation method of the purification device, belongs to the technical field of silica powder purification, and aims to solve the problems that particles cannot be classified and screened when existing silica powder is purified and screened, so that the particles are easy to block a screen, and the screening efficiency of the particles is influenced. Secondly, the existing silica powder is subjected to impurity adsorption through a roller magnet, and the adsorption surface of the roller magnet is too small, so that the impurity removal efficiency is poor. Through effective removal of particles in silica powder and up-down back-and-forth telescoping, mesh blockage can be effectively prevented, through arrangement of three-stage screening, impurity separation is effectively carried out while the screening efficiency is improved, and a screening cylinder drives a screening rod to retract, so that a screen is inclined, impurities left after filtration are effectively cleaned, next powder screening is facilitated, and the screening efficiency is improved. And the motor drives the conveying rollers to rotate for conveying, so that impurities in the filtered silica powder can be effectively sucked away, and the purification efficiency of the silica powder is ensured.

Owner:LIANYUNGANG AINA SILICON IND CO LTD

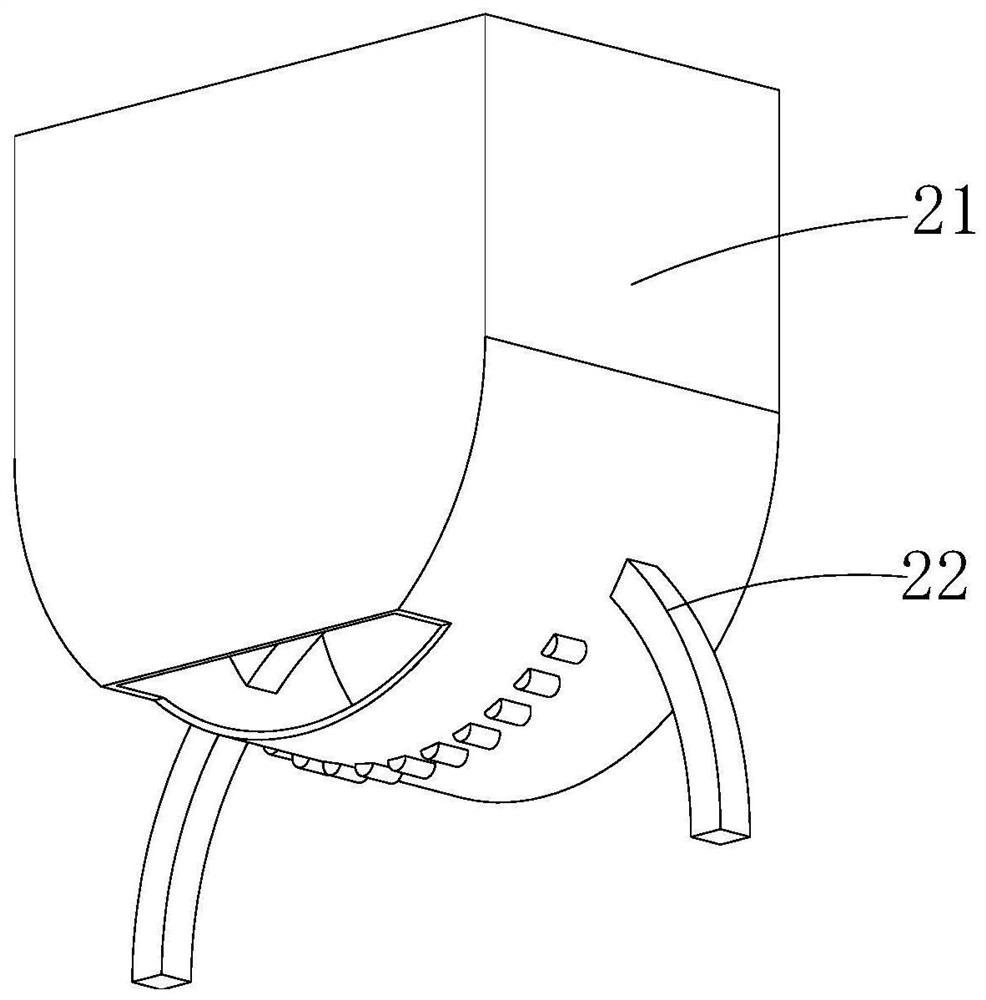

Double-layer material-dropping hopper

InactiveCN105233962AReasonable structural designSpeed up the blankingGrain treatmentsMechanical engineeringEngineering

Owner:JIANGYIN SUXIN DRYING EQUIP

Industrial raw material stirring device

PendingCN108380084AImprove stabilityAvoid noiseTransportation and packagingRotary stirring mixersDrive shaftSpray nozzle

The invention aims at providing an industrial raw material stirring device, comprising a gear box body, a drive motor, a support frame, a support base, a connection clamping piece, an output shaft, acoupling, a mixing chamber, a stirring shaft, mixing blades, a transmission shaft, a rotating chassis, a discharge hole, a lower fixing hoop, a discharge hopper, a blanking chute, a sealing top cover,a vibration feeding device, a feed hopper, a water inlet pipe, a first connecting short pipe, a corrugated steel pipe, a second connecting short pipe, a connecting rubber hose, a cleaning spray nozzle, a water suction pipe, a water suction pump, a washing water tank, a support table, an upper fixing hoop, a driving motor scramming device and a working table; the industrial raw material stirring device is characterized in that the working table is arranged at the upper end of the support frame and is fixedly connected with the support frame. The washing water tank is arranged at the upper endof the support table, and the interior of the mixing chamber can be automatically cleaned by means of the washing water, so that the labor intensity and work load of manual cleaning are reduced, the working efficiency is increased, and the workload caused by a manual cleaning operation is reduced.

Owner:弭希瑞 +4

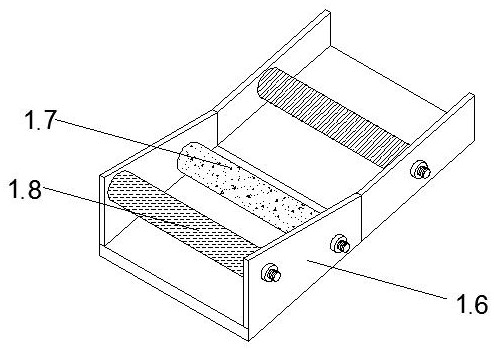

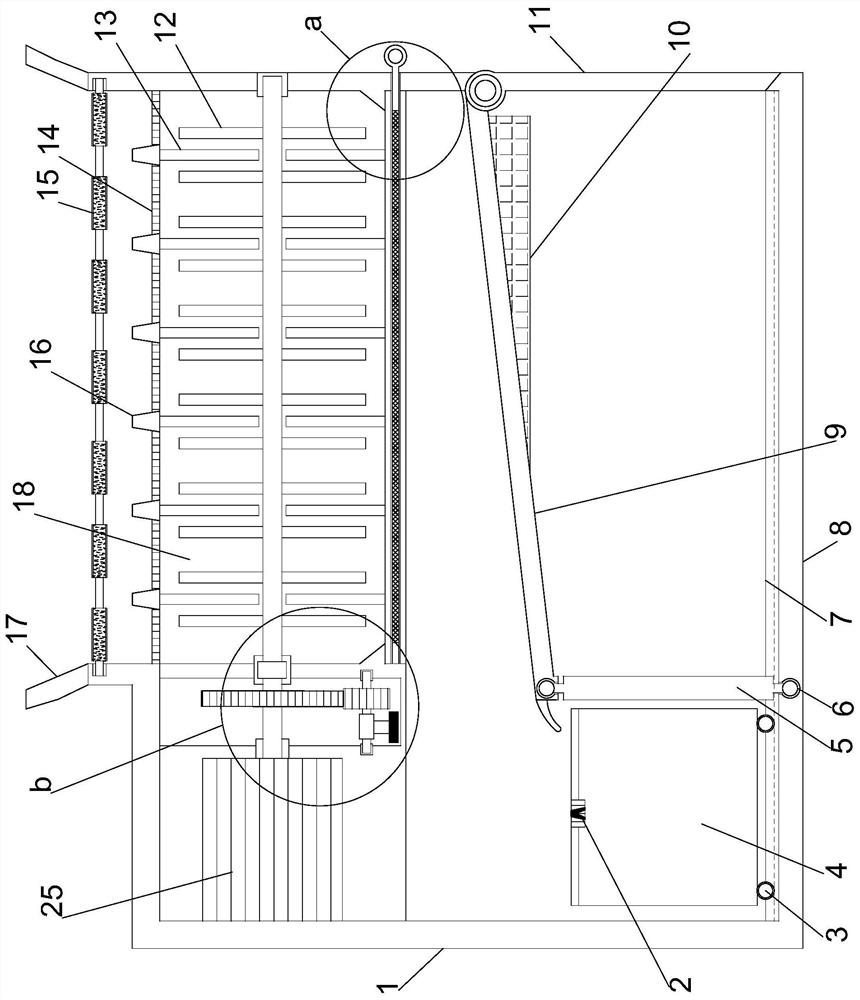

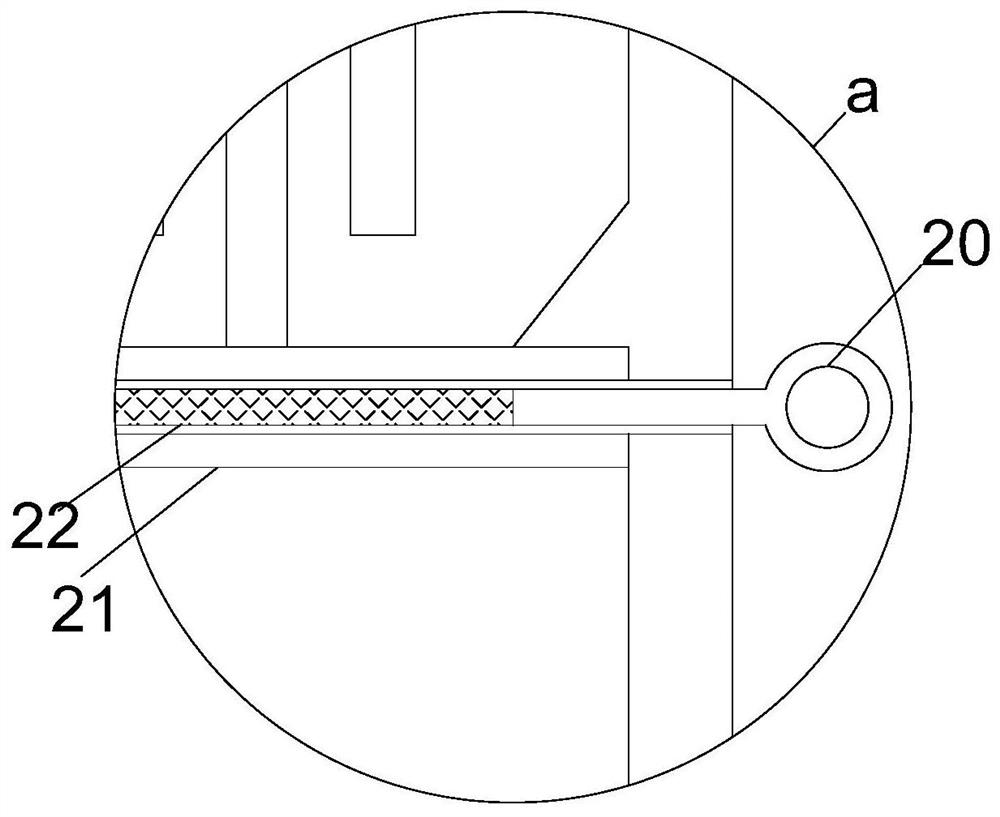

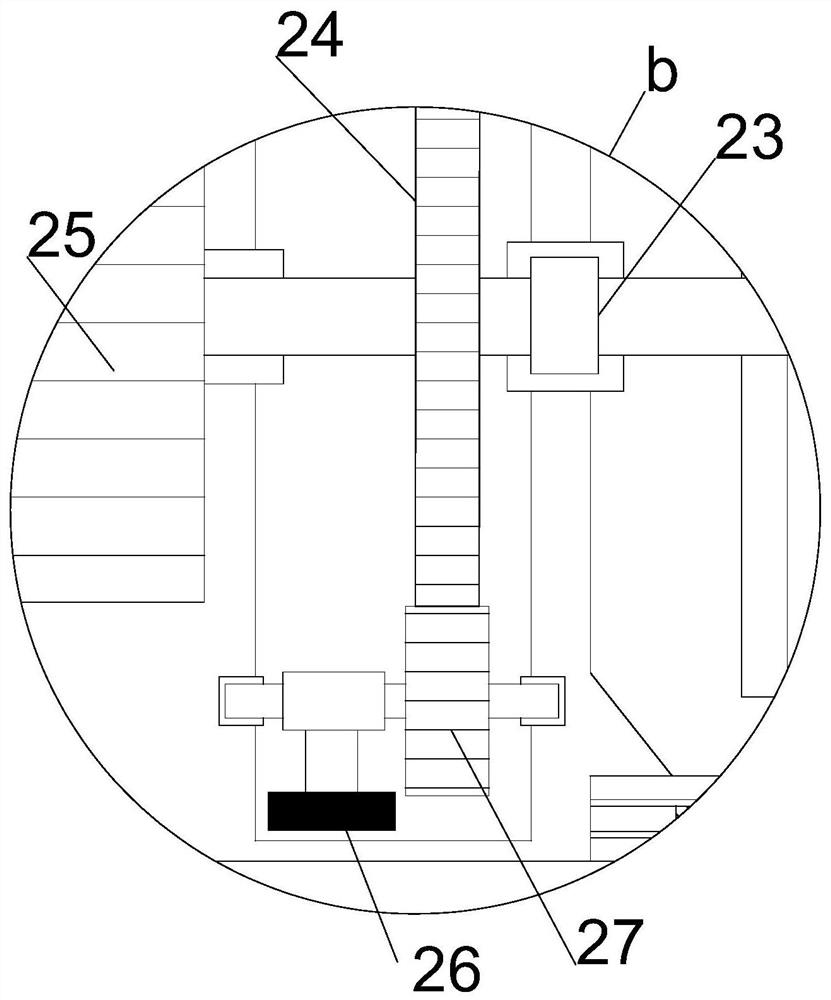

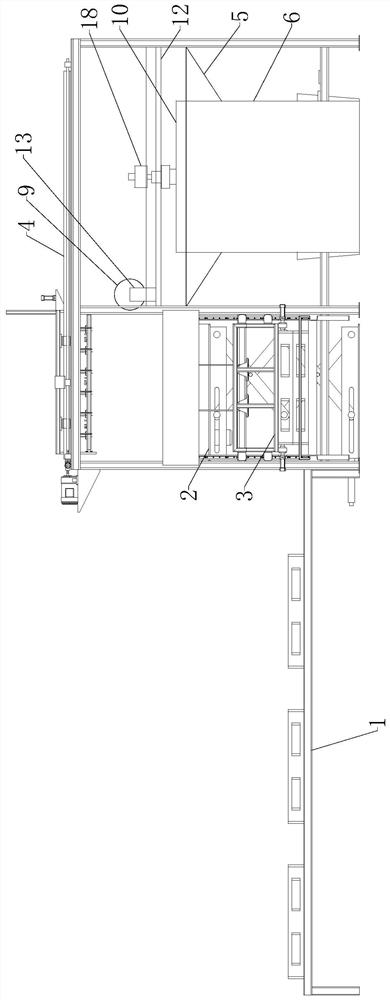

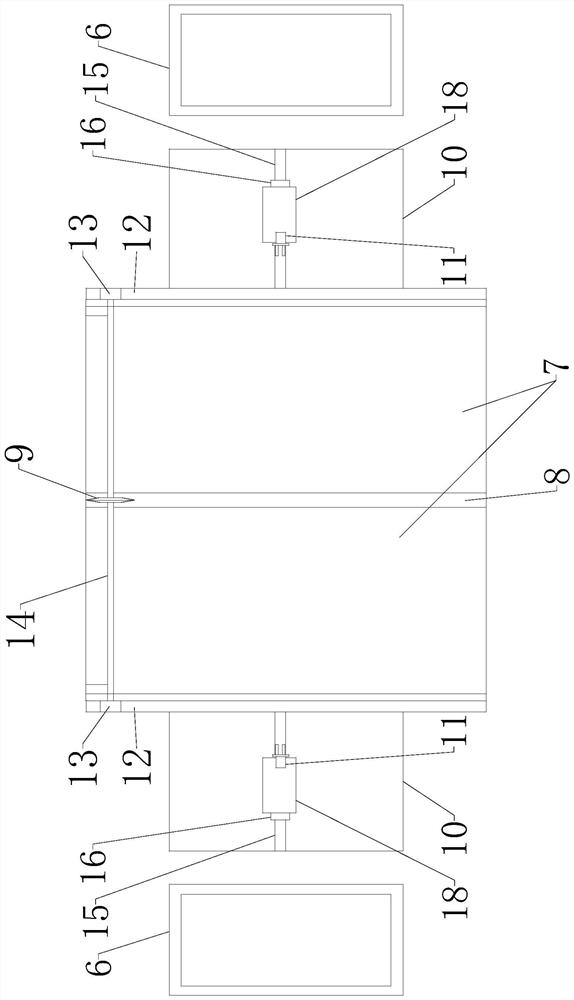

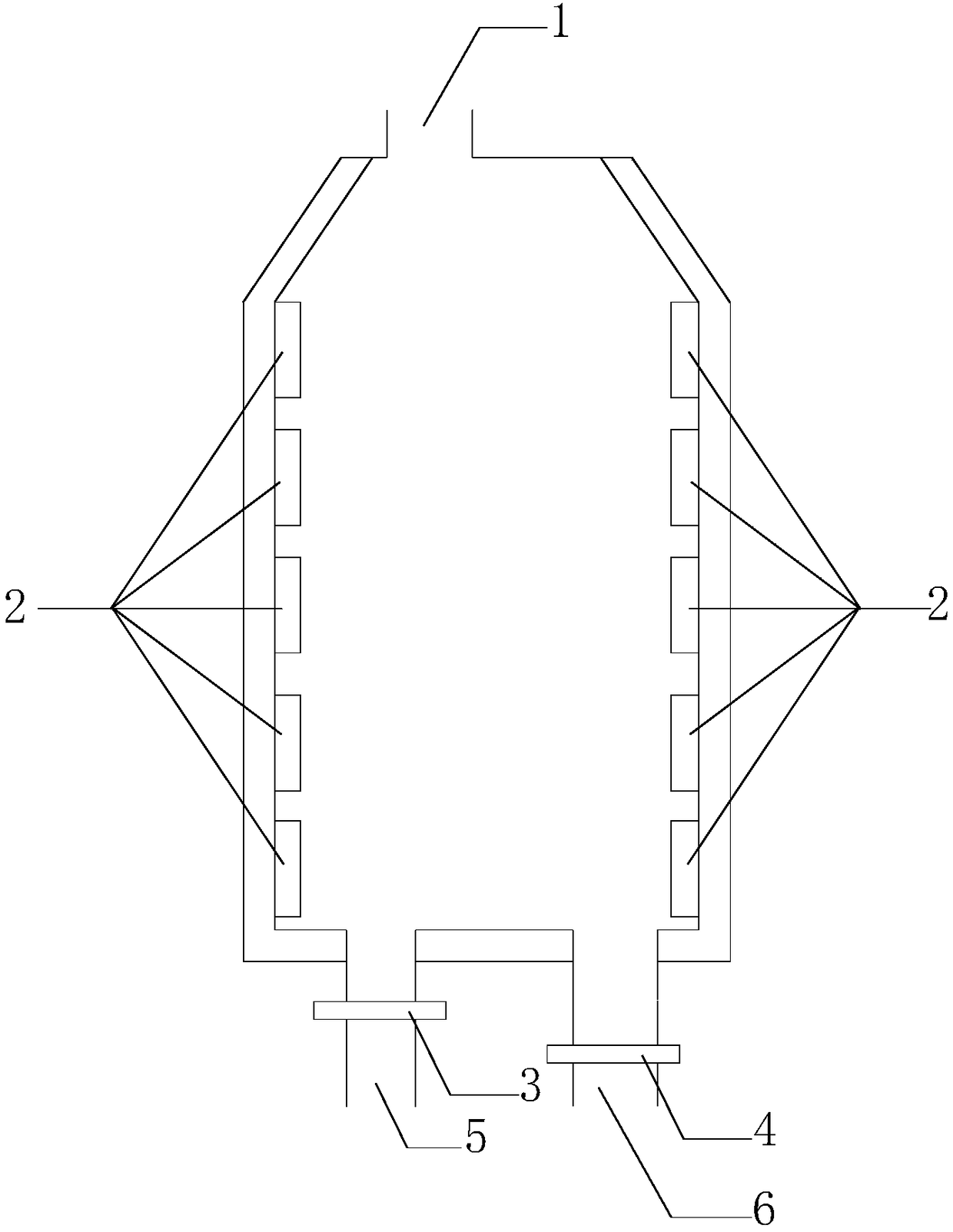

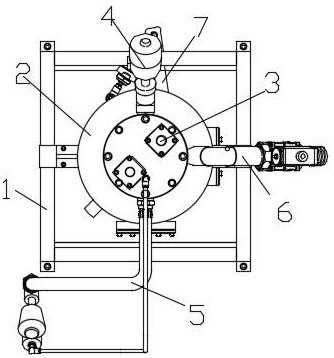

Automatic unpackaging and feeding system for high-barrier packaging film

InactiveCN112278475AReduce working noiseIncrease the blanking speedUnpacking by cuttingPalletizerStructural engineering

The invention discloses an automatic unpackaging and feeding system for a high-barrier packaging film. The automatic unpackaging and feeding system for the high-barrier packaging film comprises a conveying frame, a lifting table, a stacking mechanism, a rack, a raw material recovery hopper, a plastic bag recovery hopper and a falling mechanism, wherein the falling mechanism is arranged at the upper end of the raw material recovery hopper; the falling mechanism comprises two symmetrically-arranged movable plates which are rotatably installed at the upper end of the raw material recovery hopper;the tops of the two movable plates are used for placing high-barrier packaging film raw materials with plastic bags; a gap is reserved between the two movable plates and a movable groove is formed; acutting device is installed at the upper end of the raw material recovery hopper and comprises a blade capable of moving front and back; and the lower end of the blade stretches into the movable groove. According to the system, on the basis that the labor can be reduced, the labor cost can be reduced and the production efficiency can be increased, a low working noise is achieved, and the fallingspeed is increased.

Owner:宁波盈瑞聚合科技有限公司

Processing device of concrete for prefabricated part pouring

InactiveCN113829485AAvoid crackingImprove yieldFeeding arrangmentsArchitectural engineeringSupport plane

The invention discloses a processing device of concrete for prefabricated part pouring, and relates to the technical field of concrete processing equipment. The processing device comprises a supporting frame; a feeding mechanism used for feeding prefabricated parts is fixed to the top of the supporting frame; a prefabricating mechanism is arranged below the feeding mechanism; vibration flattening assemblies used for vibrating and flattening concrete are arranged on the left side and the right side of the prefabricating mechanism correspondingly; and a beating assembly used for assisting prefabricated part pouring is arranged on the back face of the prefabricating mechanism. Through the arrangement of the vibration flattening assemblies, stretching elastic pieces vibrate, the stretching elastic pieces drive the prefabricated parts to vibrate along with the prefabricated parts, so that concrete in the prefabricated parts is vibrated and flattened, and the situation that in the concrete pouring process, due to the fact that gaps between the prefabricated parts of arc plates are small, bubbles are likely to be generated, therefore, the prefabricated parts of the arc plates are easy to crack after being formed is avoided, and the yield of the concrete prefabricated arc plates is further improved.

Owner:李颖煜

Pulverizer for producing dimethyl cyclosiloxane

PendingCN114178033AUniform finenessAvoid cloggingGrain treatmentsElectric machineryStructural engineering

The invention discloses a crusher for producing dimethyl cyclosiloxane, which belongs to the technical field of crushers and comprises a crushing structure, a material guide structure, a crushing structure and an air guide structure. The smashing structure comprises a smashing assembly and a first motor; the feeding end of the material guiding structure corresponds to the discharging end of the smashing cavity, and a screw rod penetrating through the material guiding structure and coaxially connected with the smashing assembly is arranged in the material guiding structure. The crushing structure comprises an upper roller, a lower roller, a filtering cover, a driving part and a third motor, a crushing cavity is formed between the lower surface of the upper roller and the upper surface of the lower roller, a discharging cavity communicated with the outer edge of the crushing cavity is formed between the inner circumferential surface of a filtering net and the outer circumferential surface of the lower roller, and a discharging end communicated with the discharging cavity is formed on the outer circumferential surface of the filtering net; the air guide structure is provided with a plurality of air outlets arranged around the discharge end of the crushing structure; the raw materials can be secondarily crushed, the crushing effect is good, the fineness of the crushed raw materials is uniform, and subsequent application of products is facilitated.

Owner:枣阳惠祥有机硅有限公司

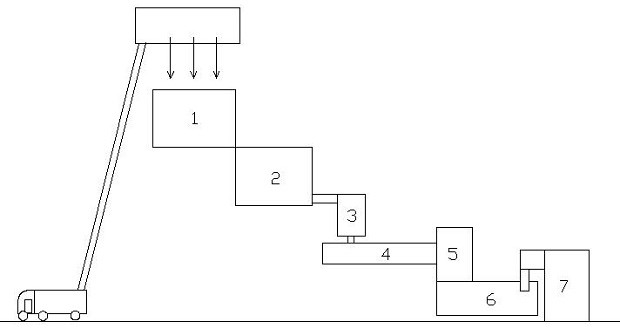

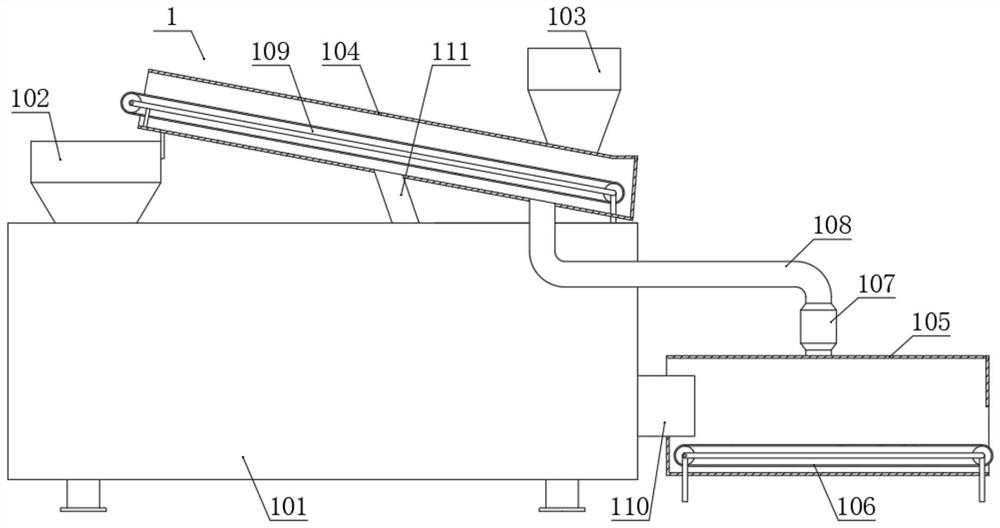

High-speed digital energy-saving forming machine and forming method thereof

The invention relates to a high-speed digital energy-saving forming machine and a forming method thereof, and aims to solve the problems that a forming machine in the prior art is likely to be blocked, low in working efficiency and high in energy consumption. According to the technical scheme, the high-speed digital energy-saving forming machine comprises a rack, feeding devices, a curing device, a cooling device, a discharging device, a mold frame and a translation device. The feeding devices are connected with the mold frame through material guns. A mold hanging bracket is further arranged on the rack and connected with the mold frame. Each feeding device comprises a material barrel stand, a feeding barrel, emptying valves, a negative pressure valve, a pressurizing mechanism, a feeding pipe and an air cylinder, wherein the material barrel stand is mounted on the rack, the feeding barrel is mounted on the material barrel stand, the emptying valves, the negative pressure valve and the feeding pipe are all mounted on the feeding barrel, the pressurizing mechanism comprises a pressurizing pipe, a pressurizing balance valve, a pressure sensor and a pressure feedback pipe, the pressurizing pipe is connected with the feeding barrel, and the pressurizing balance valve is mounted on the pressurizing pipe. The high-speed digital energy-saving forming machine is high in curing and cooling speed, high in working efficiency and low in energy consumption.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

Mechanical arm collective blanking device

ActiveCN103253541BIncrease the blanking speedSimple structurePile receiversArticle deliveryRobotic armEngineering

Owner:FUJIAN FUZHEN METAL PACKING CO LTD

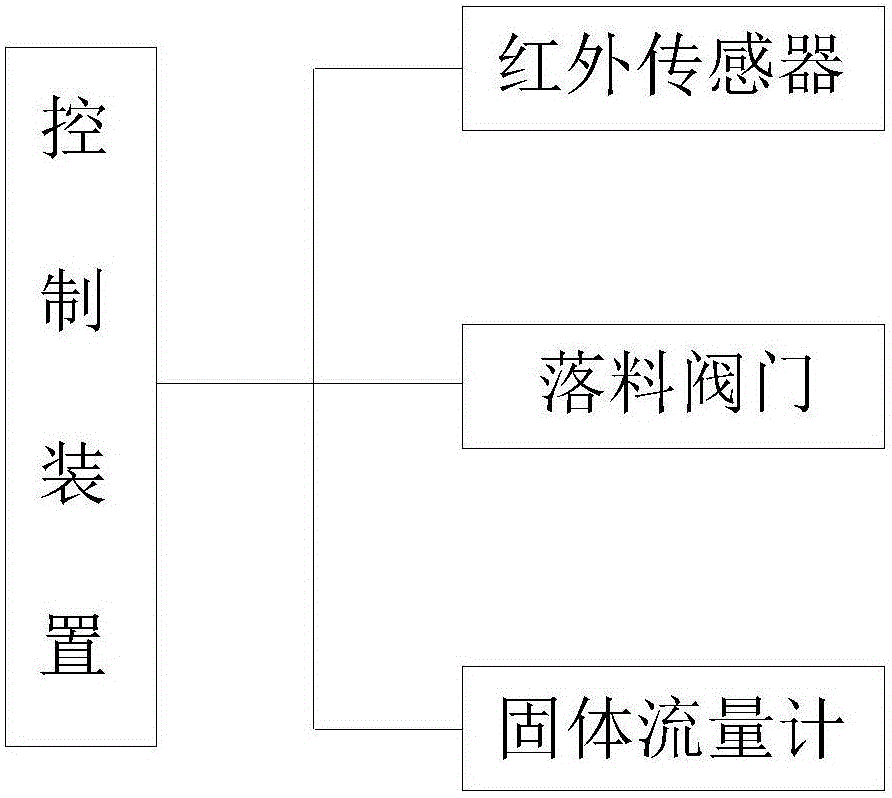

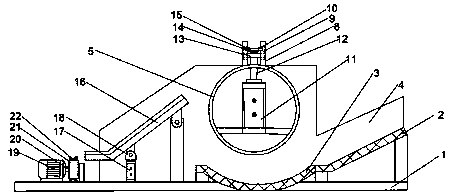

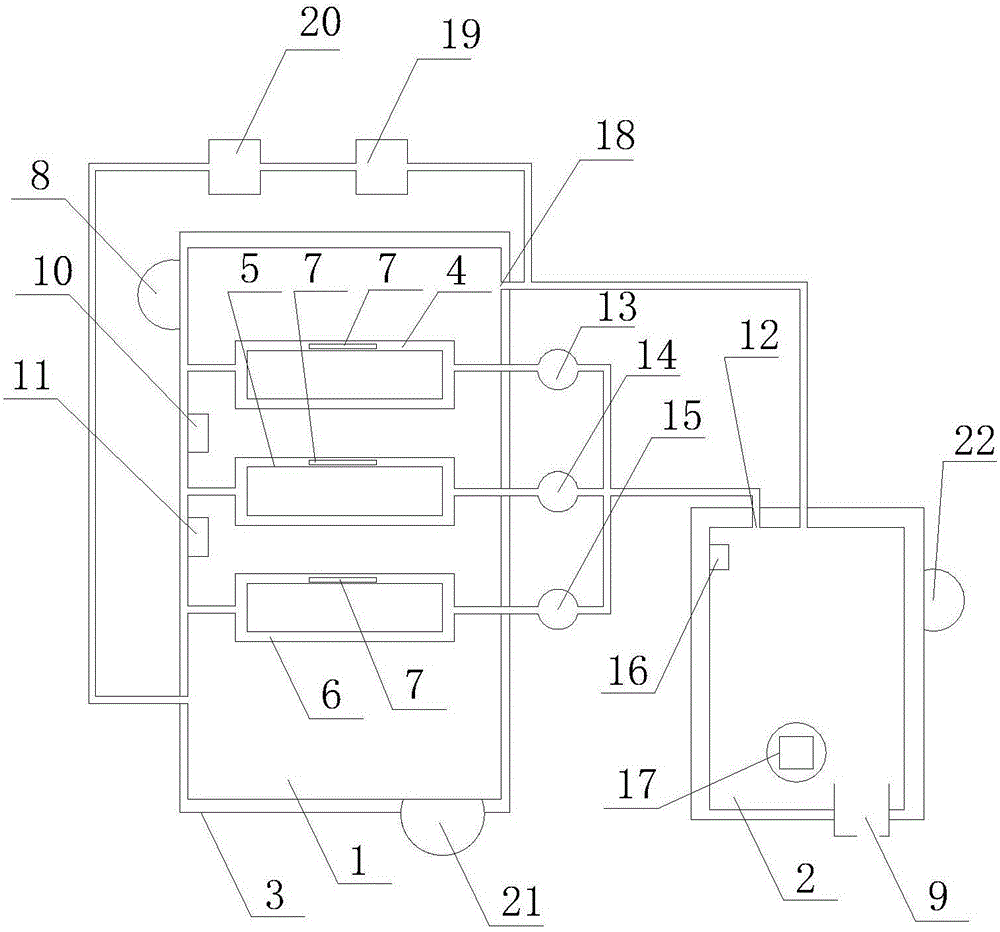

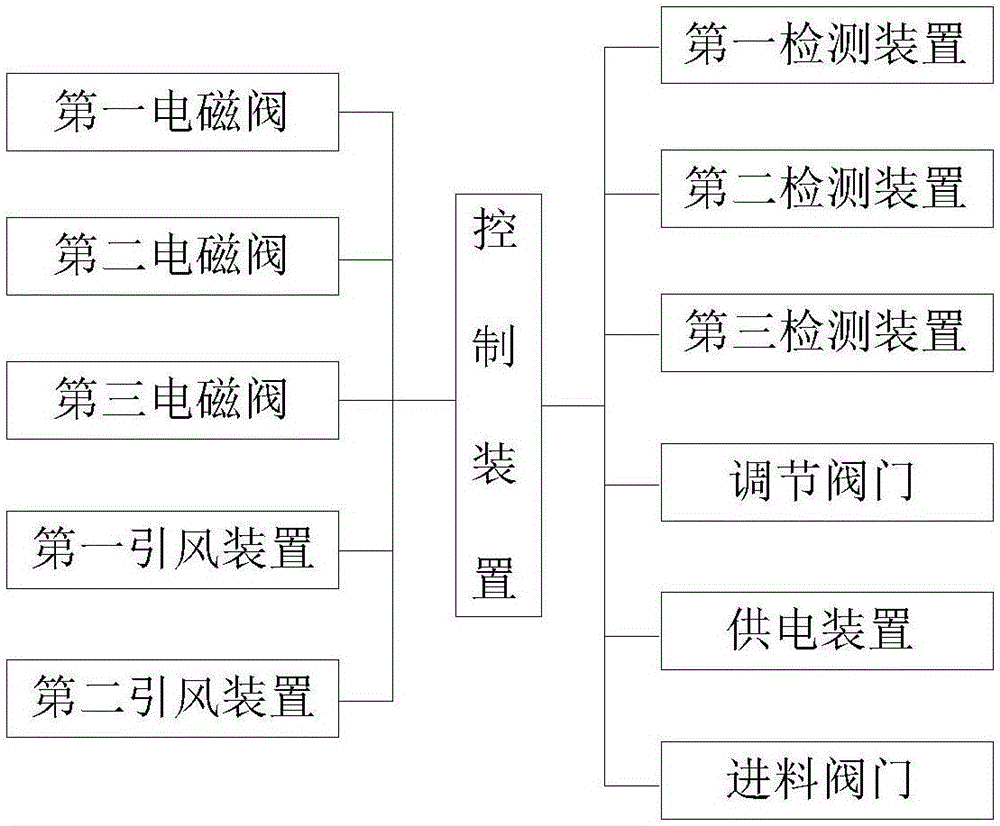

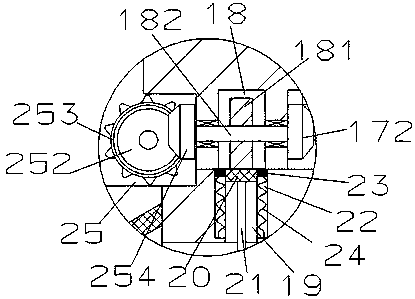

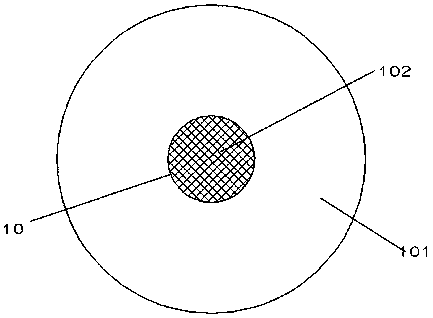

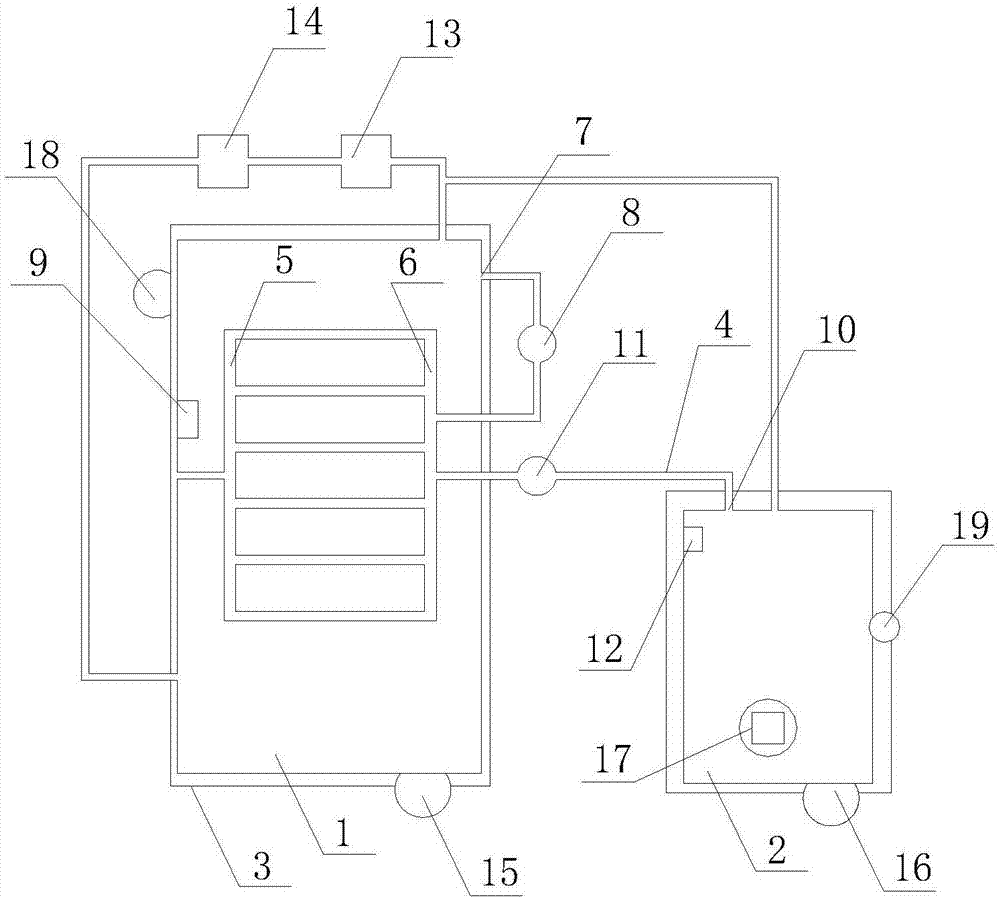

Efficient circular air inlet and automatic blanking control system of garbage incinerator

InactiveCN106838925AImprove incineration effectGuaranteed incineration effectIncinerator apparatusExhaust gasEngineering

The invention discloses an efficient circular air inlet and automatic blanking control system of a garbage incinerator. A first air inducing device is arranged on the outer wall of a shell body. A power supplying device is connected with a heating device. A blanking opening is formed in the bottom of a first cavity. An adjusting valve is arranged at the blanking opening. A first detecting device is used for detecting the temperature value of a first position. A second detecting device is used for detecting the temperature value of a second position. A third detecting device is used for detecting the temperature value of a tail gas outlet. The control device detects the temperature value T01 of the first position in the first cavity through the first detecting device, detects temperature value T02 of the second position in the first cavity through the second detecting device, calculates a difference value T0 of the T01 and the T02, obtains the temperature value T at the tail gas outlet through the third detecting device and controls the motions of the first air inducing device, a second air inducing device, a first electromagnetic valve, a second electromagnetic valve, a third electromagnetic valve, the power supplying device and the adjusting valve with commands according to T and T0.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

A continuous hydraulic processing system for unburned bricks

ActiveCN106476120BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a continuous hydraulic processing system for baking-free bricks and belongs to the field of brickmaking machines. The continuous hydraulic processing system comprises a rack and a discharge hopper located above the rack, wherein a conveying mechanism for conveying brick blocks is arranged at one end of the rack; a discharge opening communicated with the bottom of the discharge hopper is formed in the rack; a forming and pushing mechanism is arranged between the rack and the discharge hopper; the forming and pushing mechanism is connected to a first hydraulic cylinder; a forming mechanism communicated with the discharge opening is arranged below the rack; the forming mechanism is connected to a second hydraulic cylinder; raw materials in the discharge hopper pass through the forming and pushing mechanism and then enter the forming mechanism; the second hydraulic cylinder extrudes the raw materials into brick blocks and push the brick blocks onto the rack; and the first hydraulic cylinder drives the forming and pushing mechanism to push the brick blocks onto the conveying mechanism for conveying. The continuous hydraulic processing system facilitates solving the problem that an existing brickmaking machine is low in continuous production degree and complex in production process, and can realize continuous extrusion forming of the brick blocks, the production efficiency is effectively improved, the production process is simple, the processing cost is low, and improvement on production benefits of an enterprise is facilitated.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

A temperature difference control blanking system

The invention discloses a temperature control falling system which comprises a combustion cavity, a detection device, a falling device and a control device, wherein n temperature differences t1, t2,...and tn are preset in the control device; any preset temperature difference ti corresponds to two heights hi1 and hi2; the temperature distribution situation inside the combustion cavity can be acquired by the control device through the detection device; m preset temperature differences are selected by the control device; heights hj1 and hj2 corresponding to any preset temperature difference tj of the m preset temperature differences are obtained; according to the temperature distribution situation inside the combustion cavity, a practical temperature difference Tj of the heights hj1 and hj2 is obtained; the difference X of the preset temperature difference tj and the practical temperature difference Tj is obtained through calculation of the control device; the falling device is controlled by the control device to work according to the difference X.

Owner:湖南未名环保科技有限公司

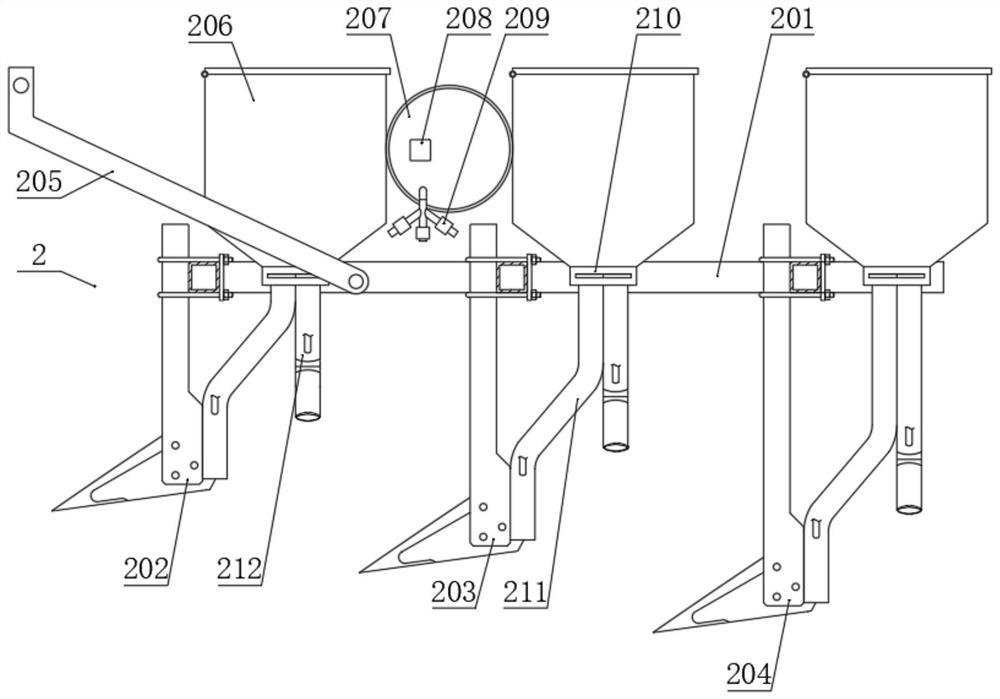

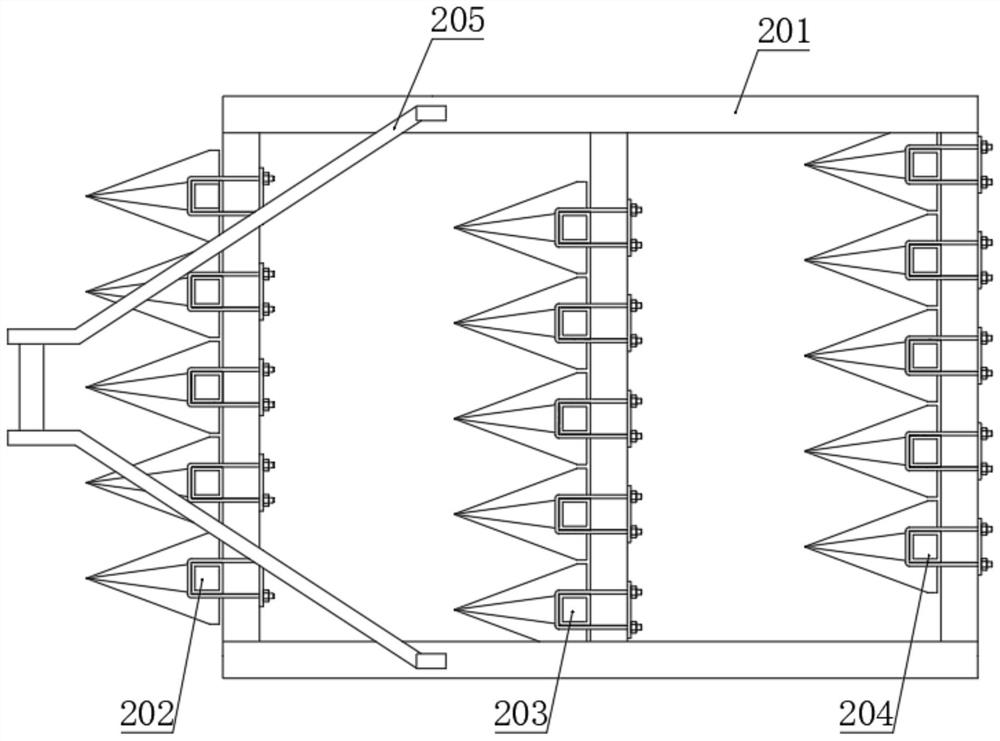

A method of improving saline-alkali soil

The invention discloses a method for improving saline-alkali soil, which comprises the following steps: using a biomass charcoal preparation device to prepare straw into biomass charcoal, mixing biomass charcoal, humic acid and cow dung, composting and fermenting, and composting and fermenting the fermented The mixture is mixed with urea and fly ash to obtain a soil improver, and the soil improver is applied to the soil by a layered application device, and then the soil applied with the soil improver is stirred by a stirring device; the present invention, by setting the layered The application device can open ditches of different depths on the soil, so that the soil conditioner can be applied into the soil of different depths, which is beneficial to the soil improvement of the deep soil, and can improve the uniformity of the soil mixing when the soil is stirred in the later stage and speed, and the first ditching group, the second ditching group and the third ditching group are staggered forward and backward. When ditching forward, three ditches, parallel and different depths can be opened at one time, realizing multi-level application. Soil conditioner.

Owner:TARIM UNIV

Exhaust and pressurization combined feeding device and feeding method thereof

ActiveCN112707171AReasonable structural designEasy to operatePlastic recyclingLarge containersEngineeringPressure feedback

The invention relates to an exhaust and pressurization combined feeding device and a feeding method thereof. In order to solve the problems that a feeding device in the prior art is slow in material falling and prone to blockage, the following technical scheme is provided: the exhaust and pressurization combined feeding device comprises a rack, a feeding barrel, an emptying valve, a negative pressure valve, a pressurization mechanism, a feeding pipe and an air cylinder. The feeding barrel is mounted on the rack. The emptying valve, the negative pressure valve and the feeding pipe are all mounted on the feeding barrel. The pressurizing mechanism comprises a pressurizing pipe, a pressurizing balance valve, a pressure sensor and a pressure feedback pipe. The pressurizing pipe is connected with the feeding barrel. The pressurizing balance valve is mounted on the pressurizing pipe. The pressure sensor is mounted on the pressurizing balance valve. One end of the pressure feedback pipe is connected with the feeding barrel, and the other end is connected with the pressure sensor. The feeding barrel sequentially comprises an upper cover, a barrel body and a lower cover from top to bottom, the upper cover and the lower cover are fixedly connected with the barrel body, and a discharge hole is formed in the lower cover. The exhaust and pressurization combined feeding device and the feeding method thereof are fast in material falling, not prone to blockage and capable of saving energy.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

A crushing device

ActiveCN108212474BIncrease the blanking speedConvenient secondary processingSievingScreeningMechanical engineering

The invention discloses a crushing or smashing device. The crushing or smashing device comprises a base and a material tank, wherein the material tank is fixedly arranged on the base through a fixed arm; a balance weight groove is formed in the inner bottom part of the base; a balancing weight is fixedly arranged in the balance weight groove; a material cavity with an upward groove opening is formed in the end surface of the top part of the material tank; a grinding cavity is formed in the material tank under the material cavity; a communicating groove is arranged between the material cavity and the grinding cavity in a communicating way; a first rotating groove stretching up and down is formed in the inner wall of the left side of the material tank; the first rotating groove is rotationally provided with a first tooth-shaped wheel and a second tooth-shaped wheel which are matched and connected with each other; the first tooth-shaped wheel is located above the second tooth-shaped wheel; a first rotating rod and a second rotating rod which stretch into the material tank are fixedly arranged on the end surfaces of the right sides of the first tooth-shaped wheel and the second tooth-shaped wheel.

Owner:JIANGSU WANLI BIOTECH CO LTD

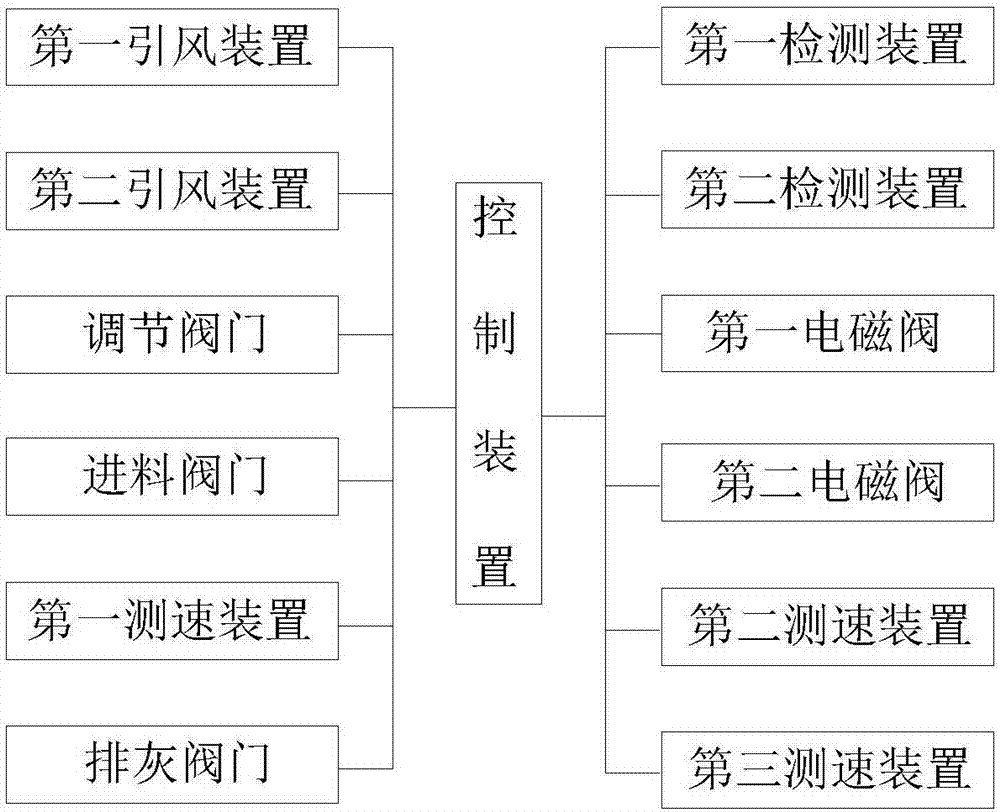

Temperature detection based novel garbage incinerator circulating control system

InactiveCN107062268AReduce the blanking speedIncrease the blanking speedIncinerator apparatusSolenoid valveControl system

The invention discloses a temperature detection based novel garbage incinerator circulating control system. A first air inducing device is arranged on the outer wall of a shell. A first solenoid valve is arranged on a first tail gas pipeline. An adjusting valve and a first speed measuring device are arranged at a falling opening. A first detection device is used for detecting the temperature value of a first position in a first cavity. A second solenoid valve is arranged on a second tail gas pipeline. A second air inducing device is arranged in a second cavity. A feeding valve and a second speed measuring device are arranged at a feeding opening. A dust discharge opening is formed in the bottom of the second cavity and provided with a dust discharge valve and a third speed measuring device. A second detection device is used for detecting the temperature value of a tail gas outlet. A control device acquires the detection value T of the first detection device and the detection value T0 of the second detection device and carries out command control over action of the first air inducing valve, the second air inducing valve, the first solenoid valve, the second solenoid valve, the adjusting valve, the feeding valve and the dust discharge valve according to the magnitude of T and the magnitude of T0.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com