Marine waste treatment device

A technology for waste treatment and marine use, applied in the direction of grain treatment, etc., can solve the problems of closed storage and waste utilization, affect the ship environment, perishable and other problems, and achieve the effect of small environmental impact, improved utilization rate, and rapid crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

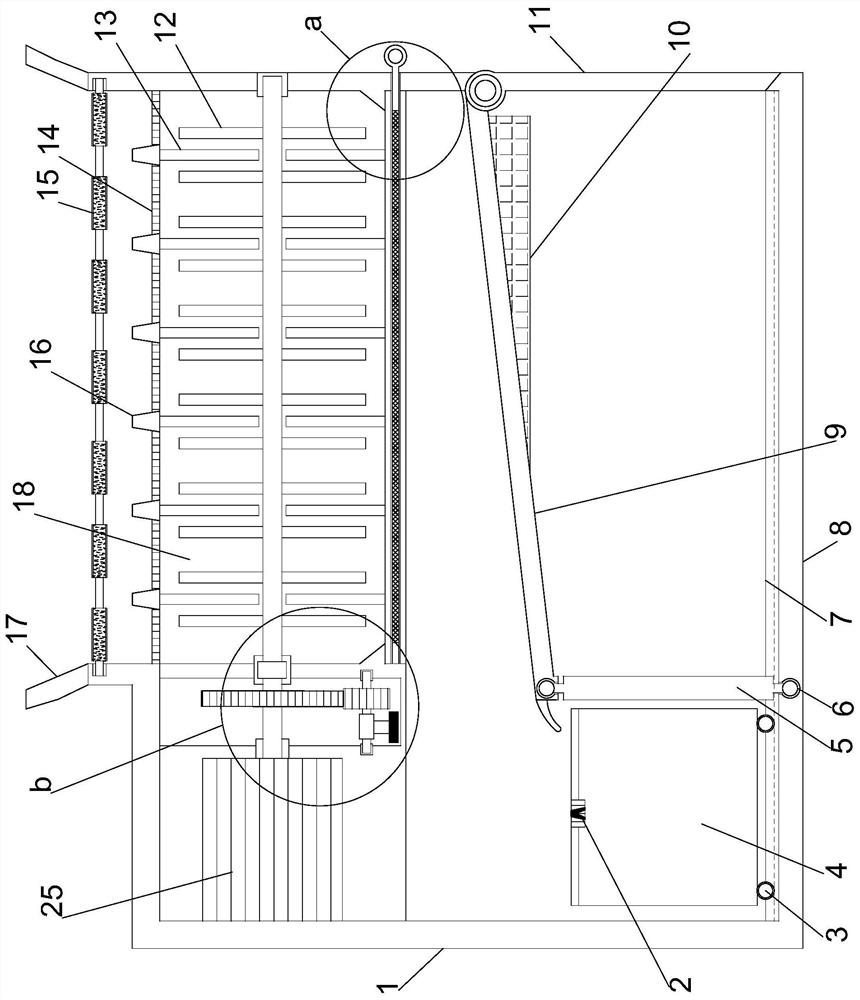

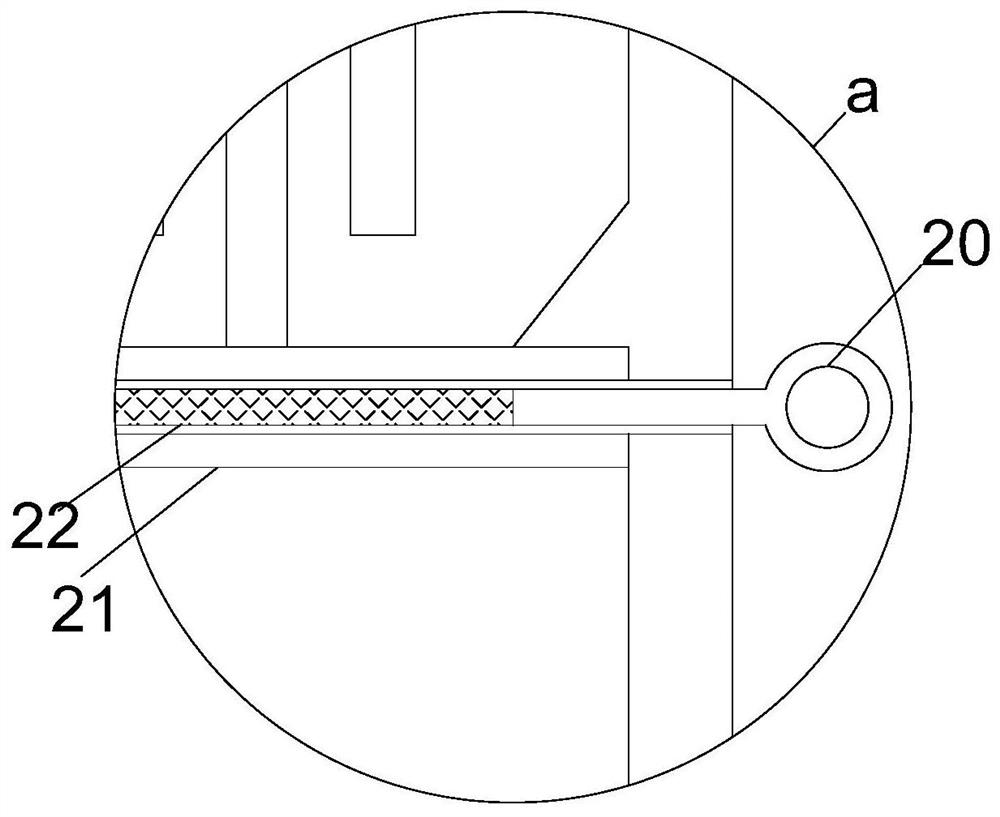

[0024] see Figure 1~4 , in an embodiment of the present invention, a marine waste treatment device includes a support installation plate 8 arranged horizontally, a support installation cylinder 1 is vertically arranged on the upper end of the support installation plate 8, and the right half of the upper end of the support installation cylinder 1 is vertically Straight out is provided with conical surface feeding cylinder 17, and the inner level of described conical surface feeding cylinder 17 is provided with passive rotation installation feeding structure, and the inner upper half part of supporting installation cylinder 1 is horizontally provided with filter material crushing structure, supports The lower half of the inside of the installation cylinder 1 is provided with a guide material storage structure. The passive rotation installation and feeding structure includes a rotation installation column symmetrically arranged front and back in the middle of the inner middle of ...

Embodiment 2

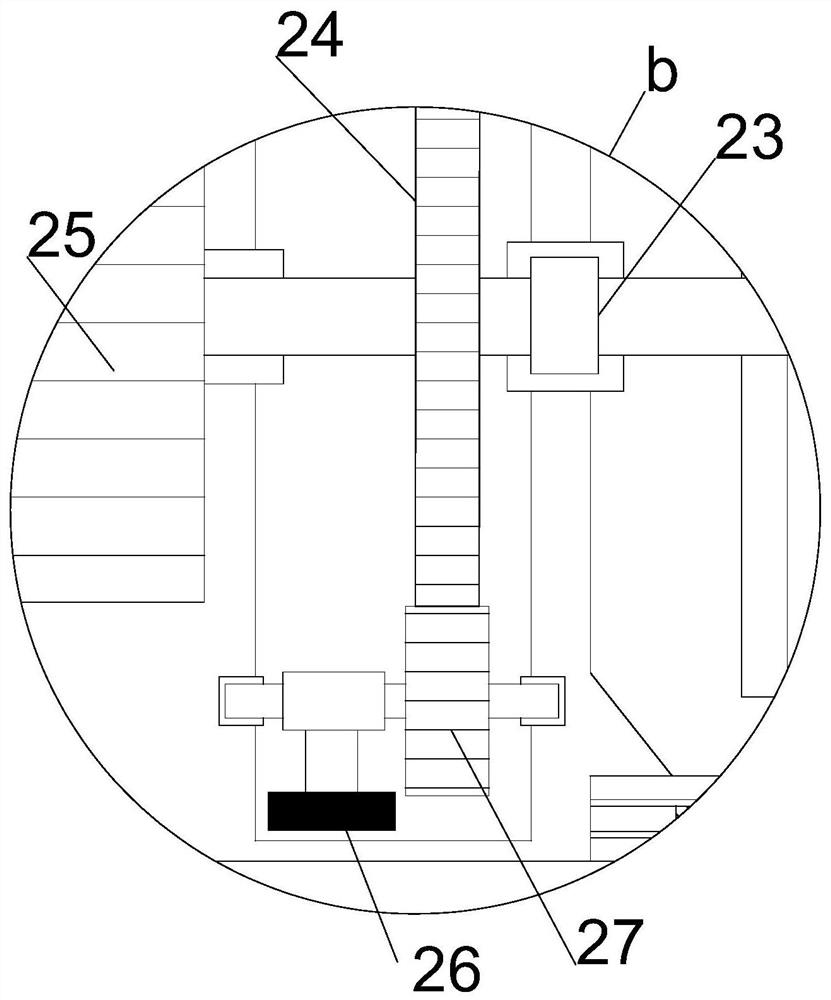

[0029] On the basis of Embodiment 1, through the driving gear 24 and the transmission gear 27 transmission ratio transmission, the high-speed rotation of the eccentric vibrating wheel 26 is realized, so that the whole device realizes vibration, greatly improving the speed of blanking, and the storage tank 4 is full The back cover is covered with a sealing cover plate. In the closed space on the lower side of the material guide plate 9, the gas generated is discharged through the overflow valve 2 and absorbed by the air cleaner 10. When it needs to be cleaned, or the fermentation has been completed, it can be directly The output is used, which greatly improves the utilization rate of waste, and has little impact on the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com