Automatic unpackaging and feeding system for high-barrier packaging film

A packaging film and high-barrier technology, applied in the field of automatic unpacking and feeding system of high-barrier packaging film, can solve problems such as large noise, and achieve the effect of increasing blanking speed and low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

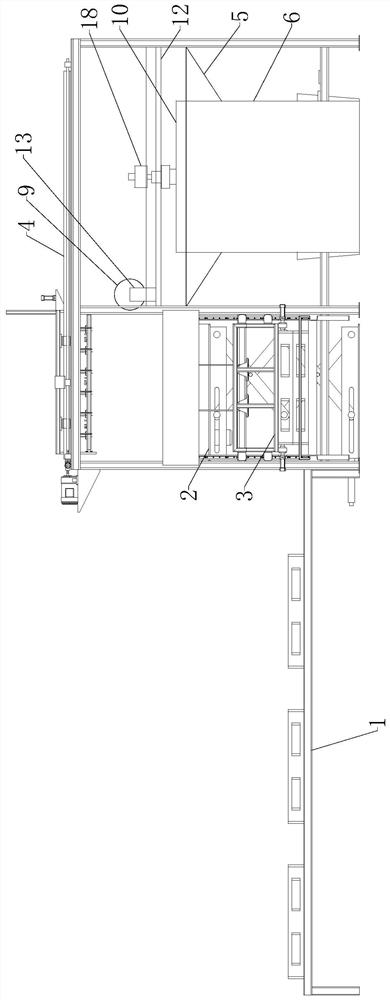

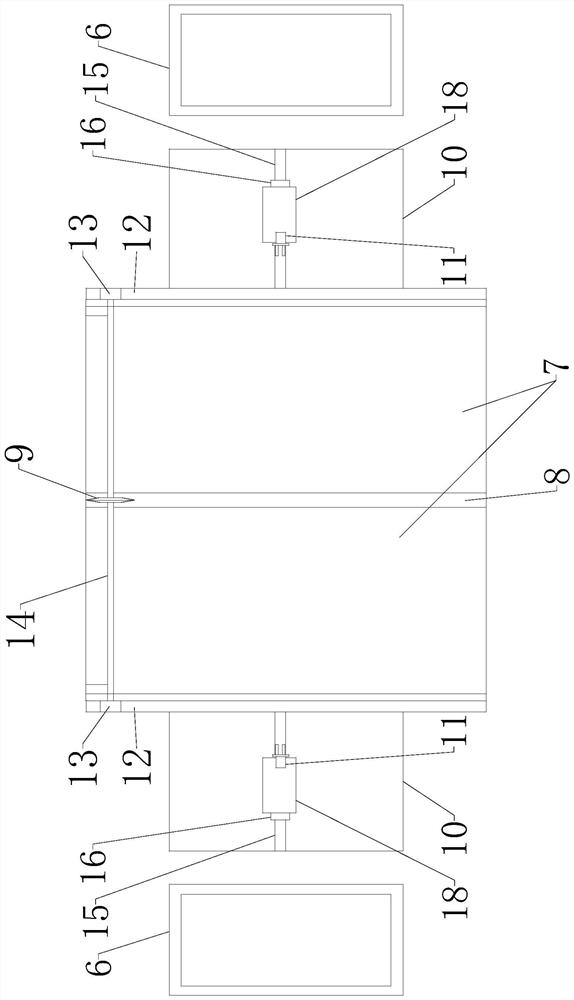

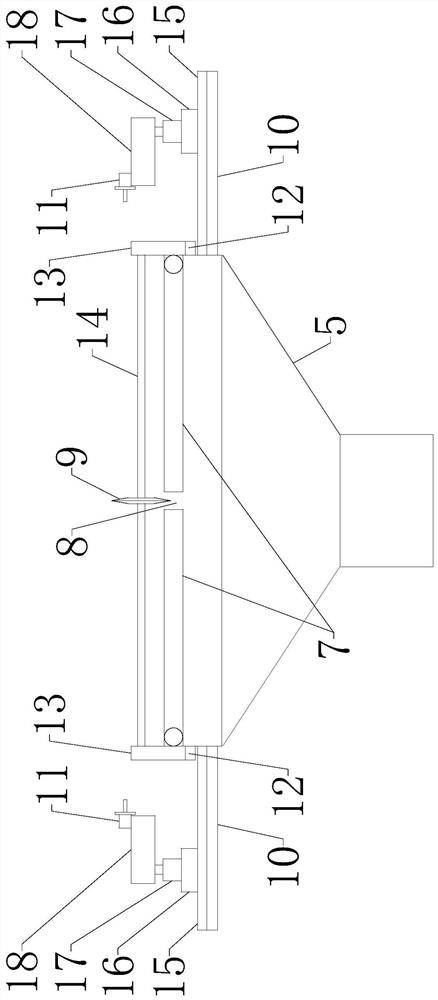

[0019] Such as figure 1 — image 3 As shown, the high-barrier packaging film automatic unpacking and feeding system includes a conveyor frame 1, a lifting platform 2, a palletizing mechanism 3, a frame 4, a raw material recovery bucket 5 and a plastic bag recovery bucket 6, and it also includes a blanking mechanism , the blanking mechanism is arranged on the upper end of the raw material recovery bucket 5, and the blanking mechanism includes two symmetrically arranged movable plates 7 that are rotatably installed on the upper end of the raw material recovery bucket 5. For packaging film raw materials, there is a gap between the two movable plates 7 to form a movable groove 8. A cutting device is installed on the upper end of the raw material re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com