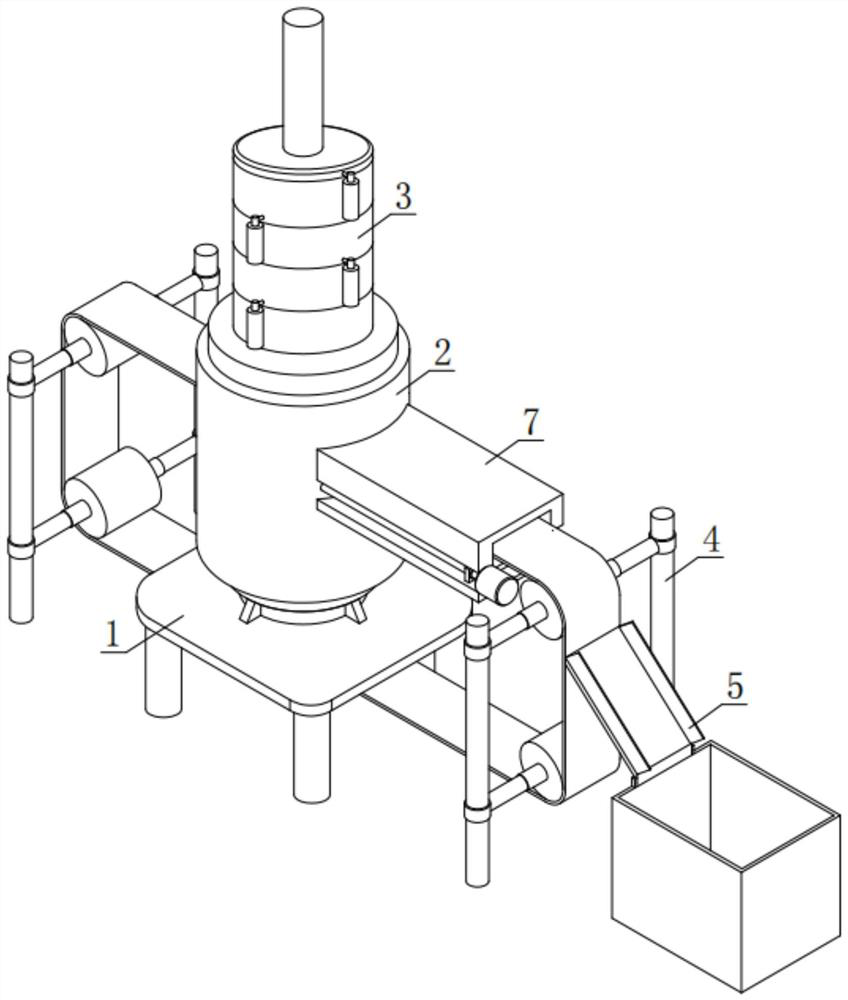

Purification device for production of electronic-grade silica powder and implementation method of purification device

A technology of electronic-grade silicon micropowder and silicon micropowder, which is applied in the direction of cleaning devices, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of small magnetic adsorption surface of rollers, affecting the efficiency of sieving materials, and unable to classify and sieve particles. Achieve the effect of preventing mesh clogging and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

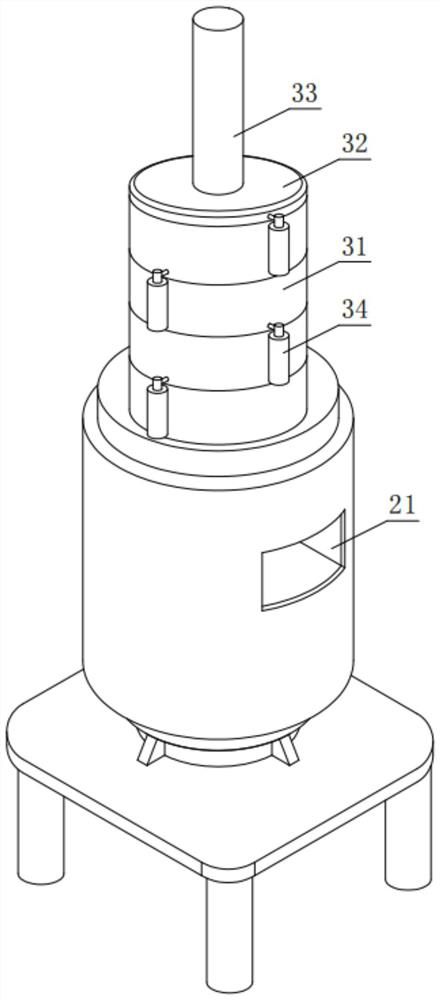

Method used

Image

Examples

Embodiment approach

[0044] In order to better demonstrate the implementation process of the purification device for the production of electronic-grade silicon micropowder, this embodiment proposes an implementation method of the purification device for the production of electronic-grade silicon micropowder, including the following steps:

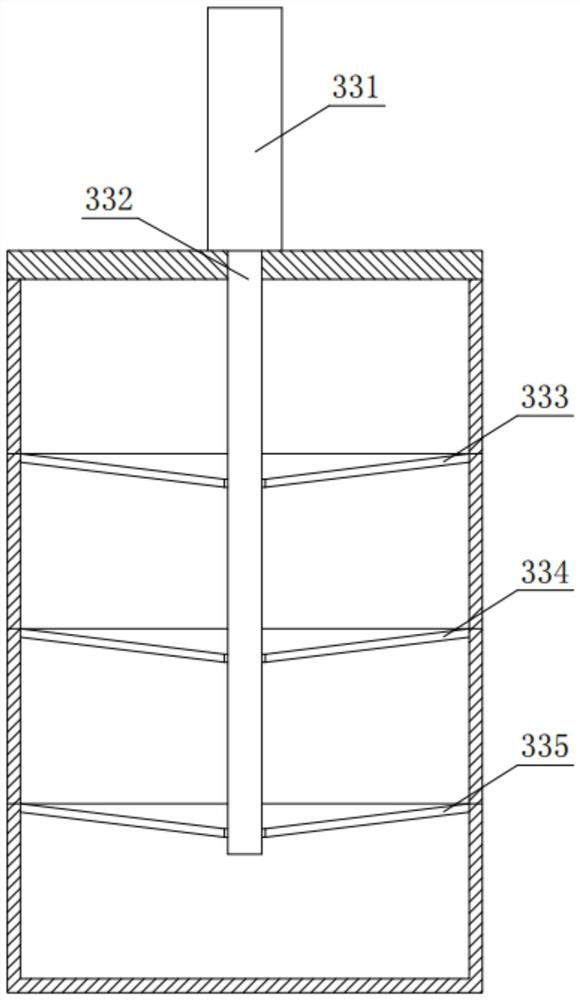

[0045] Step 1: Put silicon micropowder on the grading sieve material 33 in the outer casing 31, and the sieve material cylinder 331 drives the sieve material rod 332 to expand and contract, thereby driving the first sieve material net 333, the second sieve material net 334 and the third sieve material net The material net 335 lifts back and forth, and the first sieve material net 333, the second sieve material net 334 and the third sieve material net 335 classify and filter the silicon micropowder, effectively removing the particles in the silicon micropowder;

[0046] Step 2: The sieved silicon-removing micropowder falls to the electromagnetic conveying network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com