Steel bar straightening and shearing machine and steel bar straightening and shearing method

A technology of cutting machine and cutting mechanism, which is applied in the field of steel bar straightening and cutting machine and steel bar straightening and cutting, and can solve the problems of poor quality of welded mesh, bending of steel bar ends, slow falling speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

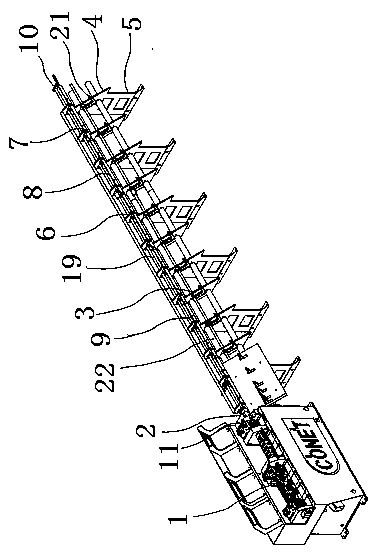

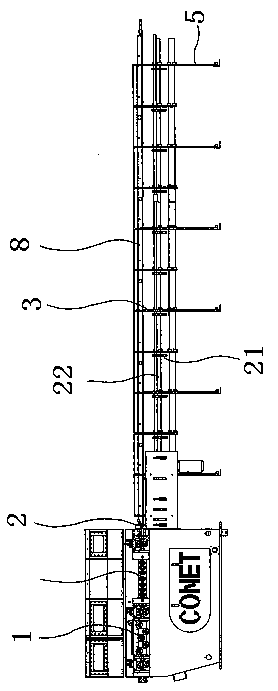

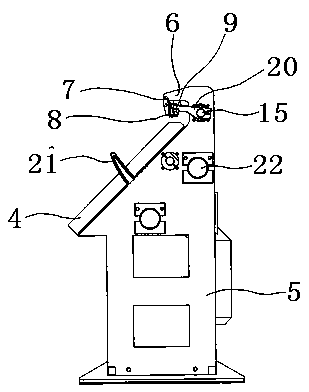

[0043] The structure and operating principle of the steel bar straightening and cutting machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] Such as figure 1 , figure 2 with image 3As shown, the structure diagram of the steel bar straightening and cutting machine of the present invention, the steel bar straightening and cutting machine of the present invention includes a straightening mechanism 1, a cutting mechanism 2 and a discharge mechanism 3, and the discharge mechanism 3 includes a frame with a blanking ramp 4 Body 5, an inverted "L"-shaped hook 6 is arranged above the frame body 5, and an "L"-shaped angle steel 8 is connected to an "L"-shaped angle steel 8 near the front lower end of the suspension hook 6 through a movable chain flap 7, and the vertical edge 81 of the angle steel 8 It is movably connected with the movable chain flap 7, and a channel steel 9 with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com