Municipal waste treatment device with water source separation function

A municipal garbage and processing device technology, applied to grain processing, manufacturing tools, presses, etc., can solve problems such as wasting resources, reducing garbage processing efficiency, and affecting incineration effects, achieving efficient separation, improving garbage processing efficiency, and ensuring incineration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

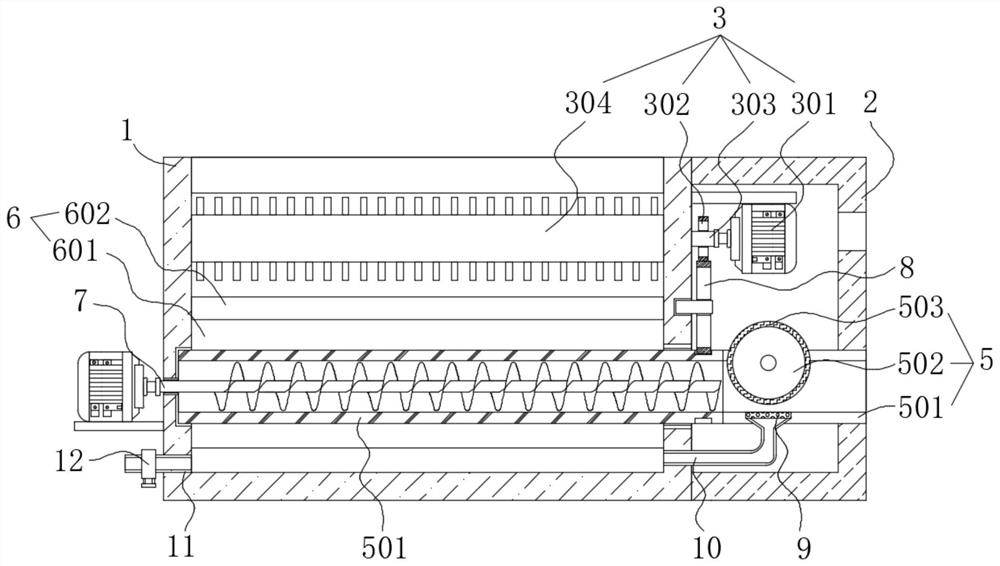

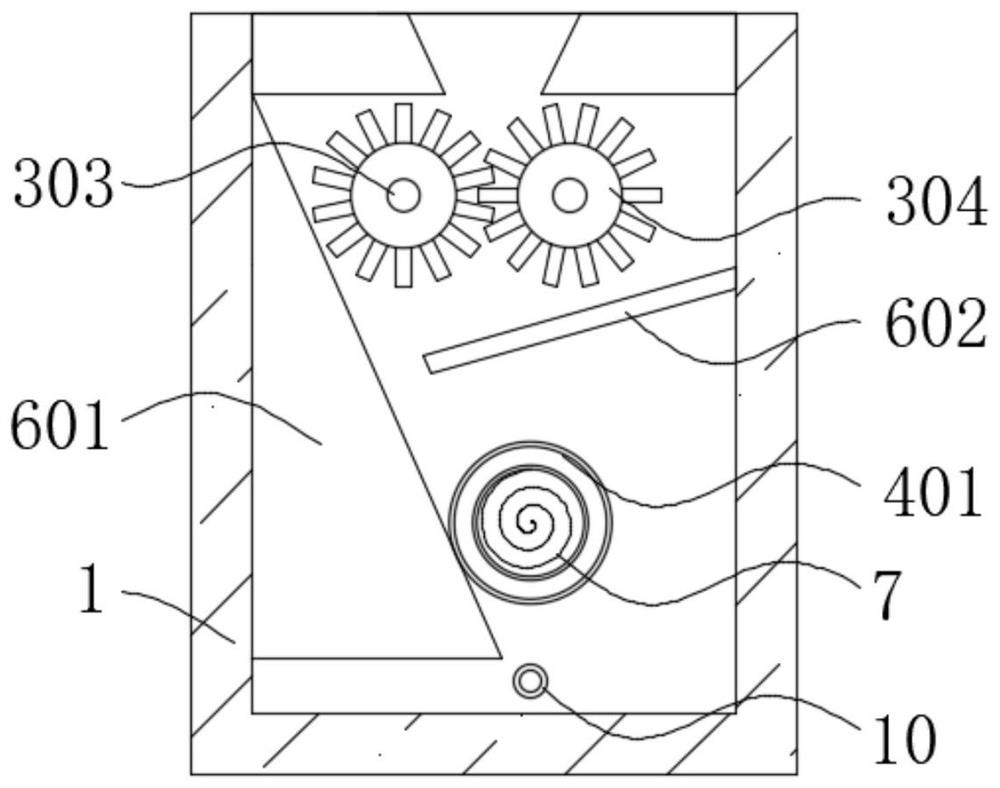

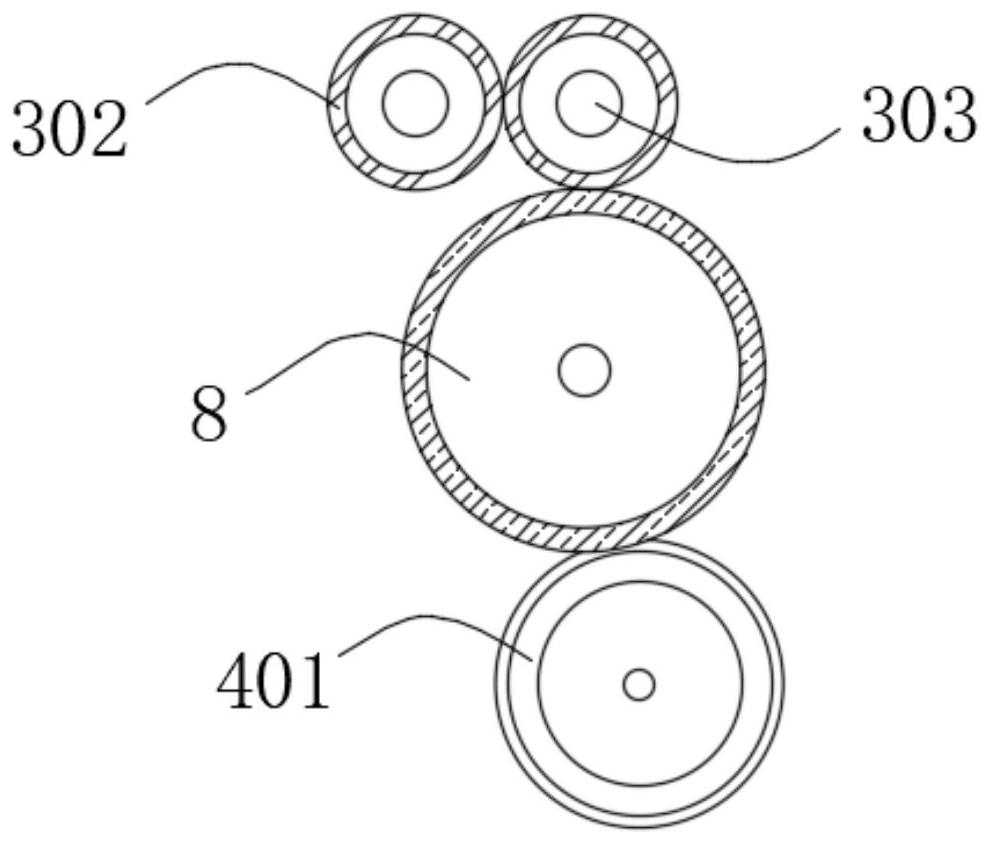

[0022] like Figure 1-4 As shown, a municipal waste treatment device with water source separation includes a first box body 1, a second box body 2, a crushing component 3, a solid-liquid separation component 4, a discharging component 5, a material guiding component 6, an auger 7 and Drain pipe 11.

[0023] The first box 1 is adjacent to the second box 2, the first box 1 is located on the left side, and the second box body 2 is located on the right side. The arrangement of the first box body 1 plays a supporting role for the whole device, and the arrangement of the second box body 2 facilitates the protection of some parts in the device, and at the same time makes the whole device more beautiful.

[0024] The crushing assembly 3 includes a motor 301, two first gears 302, two rotating rods 303 and two crushing rollers 304; the two first gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com