Garbage incinerator efficient circulation controlling system

A garbage incinerator and cycle control technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of land and water pollution, increase of garbage, air pollution, etc., to improve the incineration effect, prolong the service life, and ensure The effect of the burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

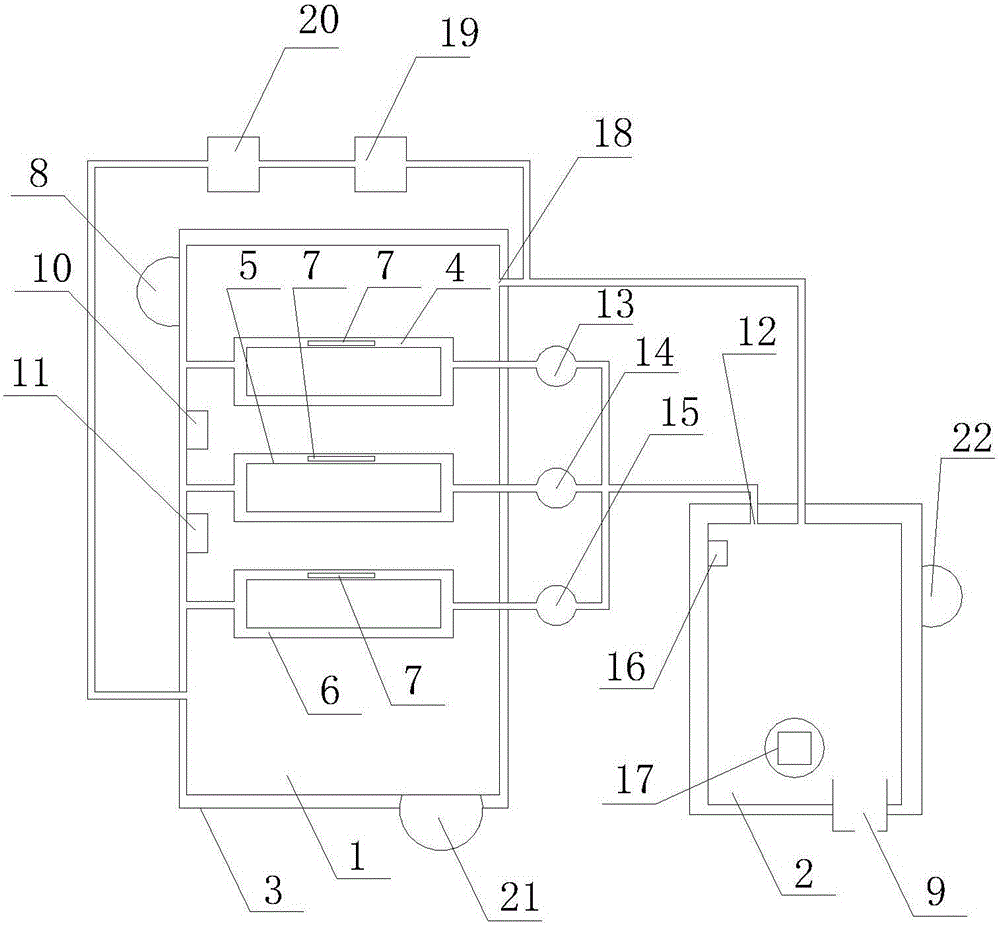

[0027] like figure 1 , figure 2 as shown, figure 1 , figure 2 It is a high-efficiency circulation control system for a garbage incinerator proposed by the present invention.

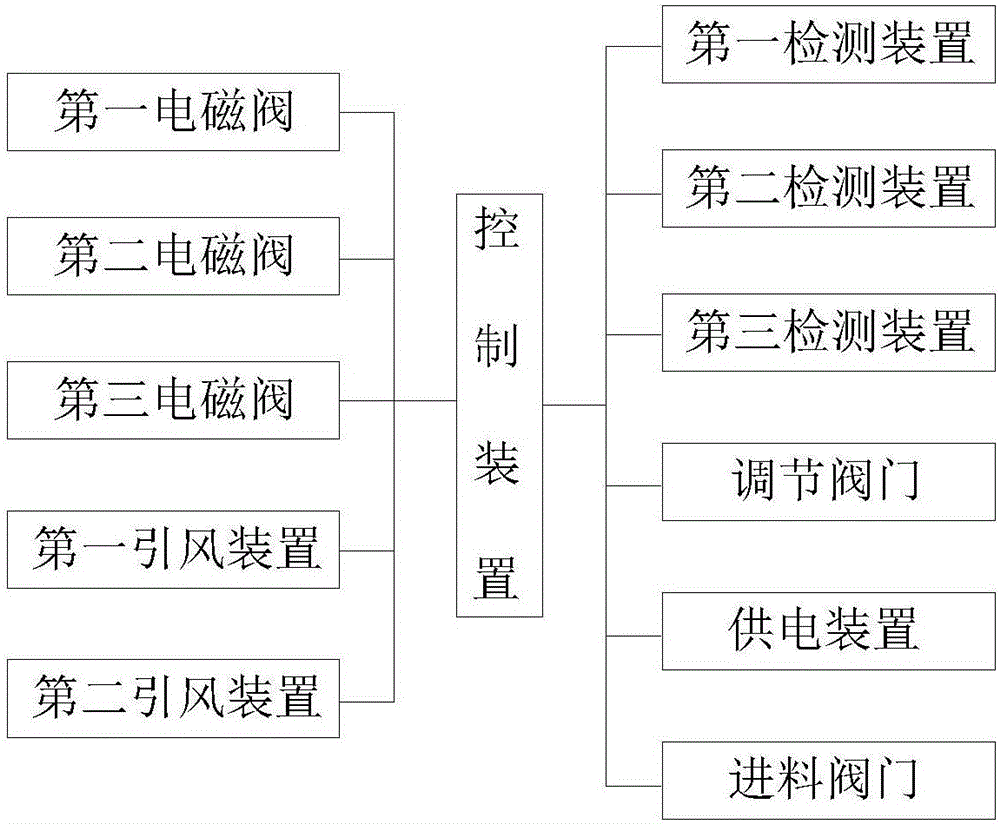

[0028] refer to figure 1 , figure 2 , the high-efficiency cycle control system for waste incinerators proposed by the present invention includes: a first cavity 1, a second cavity 2, a housing 3, a power supply device, and a control device;

[0029] The first cavity 1 is located inside the housing 3, and a gas channel for gas circulation is formed between the outer wall of the first cavity 1 and the inner wall of the housing 3; the outer wall of the housing 3 is provided with a first air induction device 8, the first air induction The wind device 8 is used to drive the gas flow in the gas passage; the first cavity 1 is sequentially provided with a first pipeline loop 4, a second pipeline loop 5, a third pipeline loop 6, a first pipeline loop 4, The second pipeline circuit 5 and the third pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com