Small collaborative incinerator

An incinerator, a small technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of segregation, affect incineration effect, difficult to mix uniformly, etc., to reduce consumption, improve incineration quality, and ensure uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

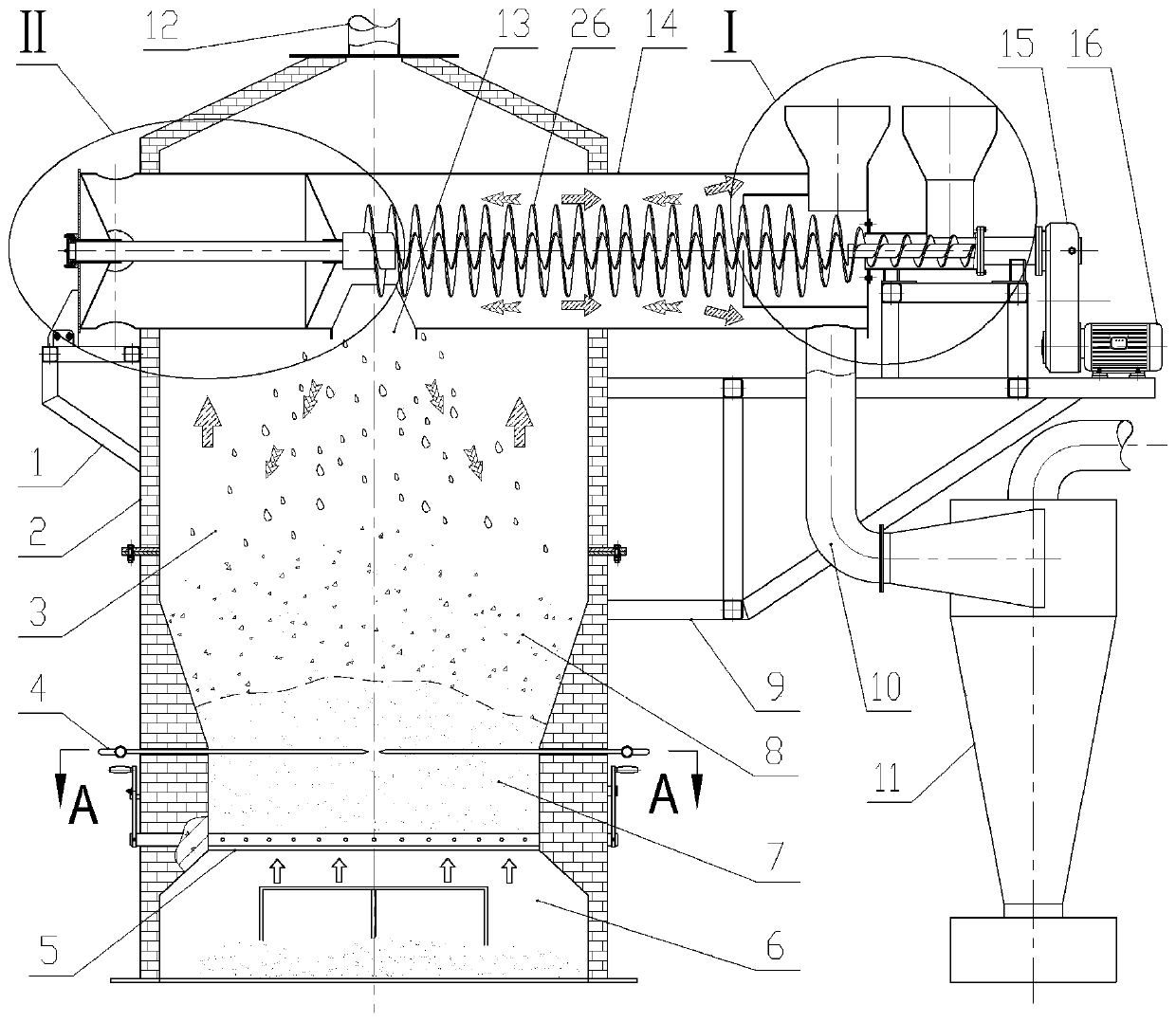

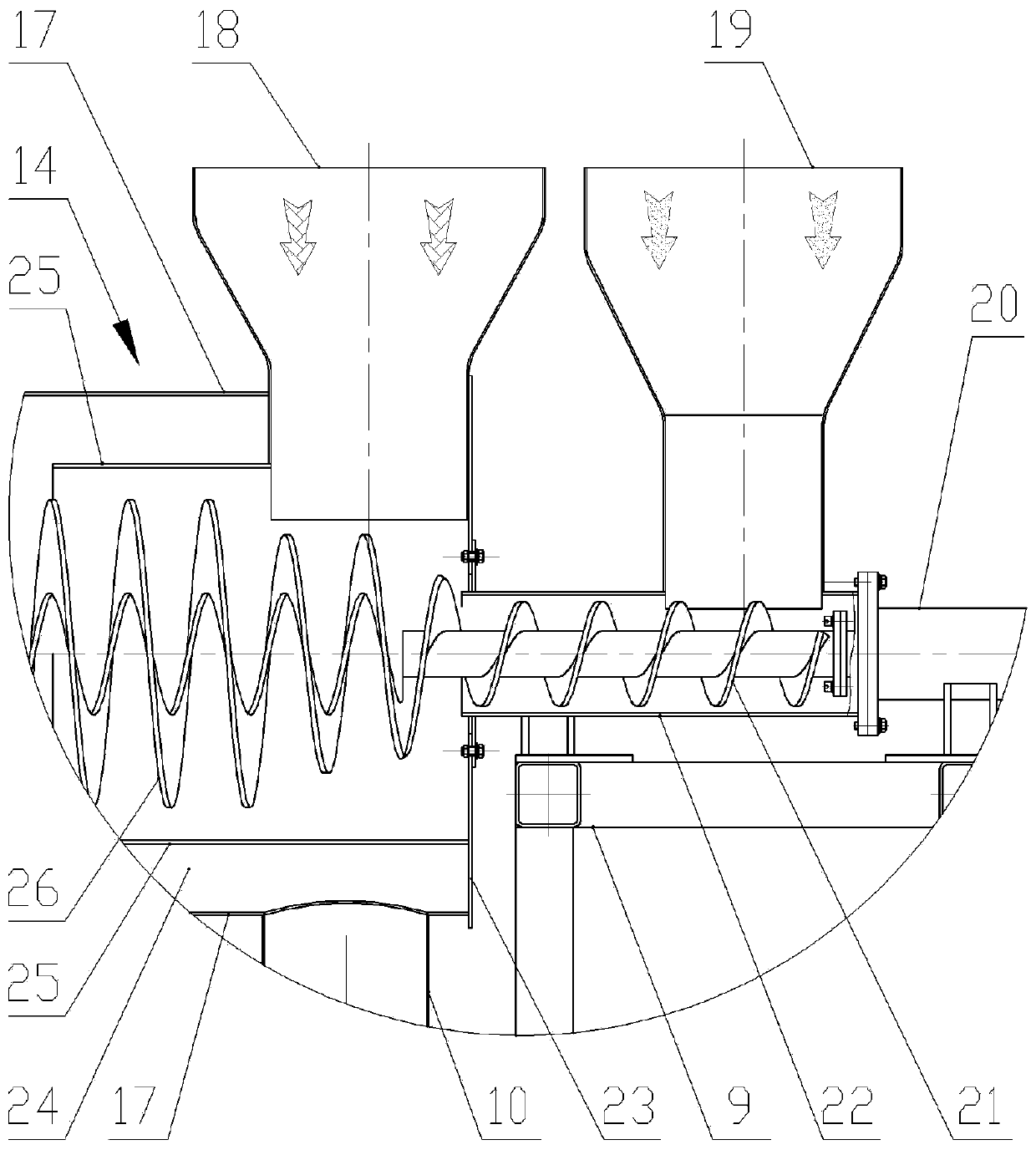

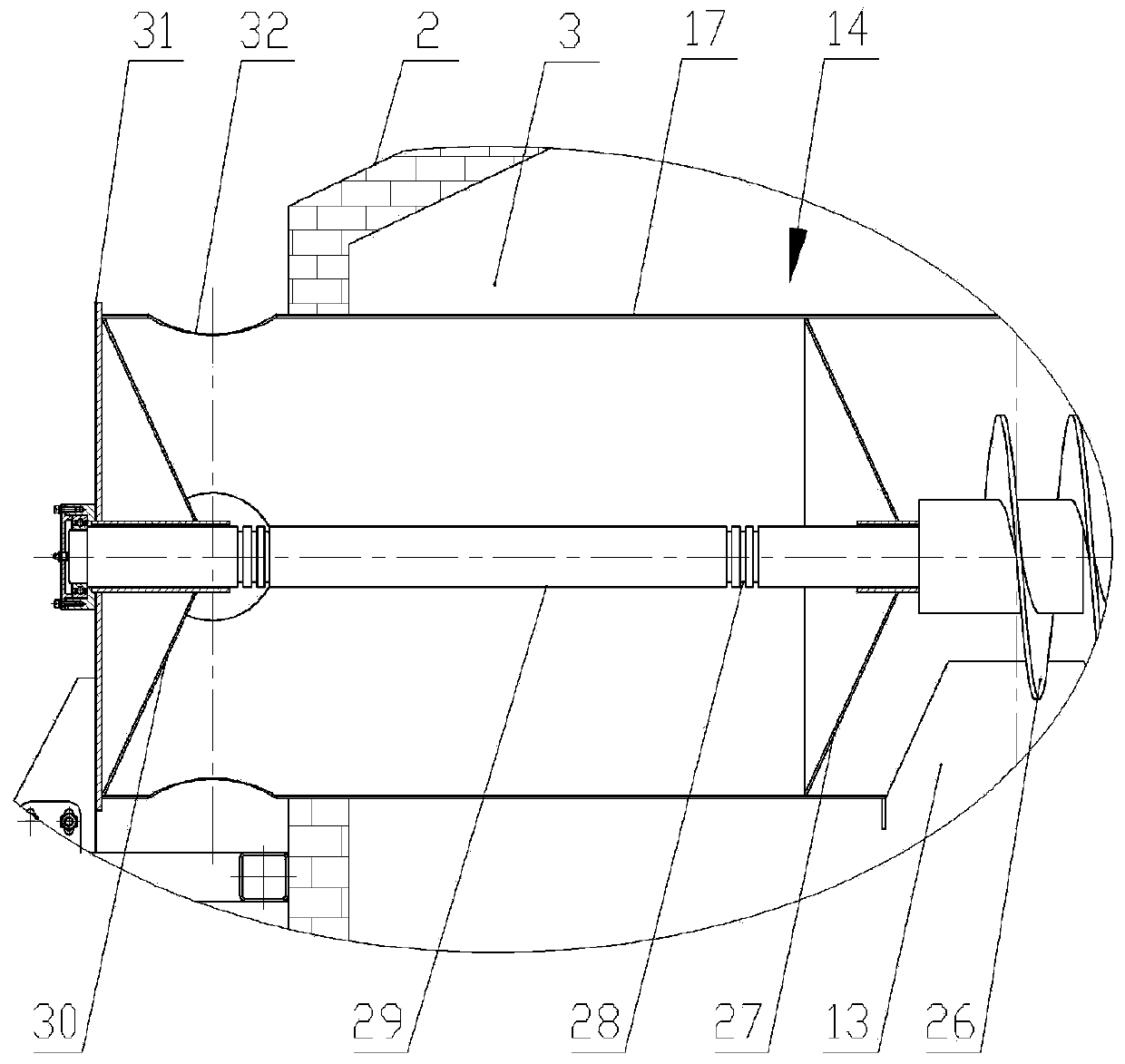

[0055] A small collaborative incinerator, referring to the attached Figure 1-6 , including a furnace body 2 with an internal cavity and a feed system 14, a small support seat 1 and a large support seat 9 are respectively provided on the opposite outer wall surfaces of the furnace body 2, and a spare smoke exhaust port 12 is provided on the top, and the interior A fire grate 5 is provided, the space above the fire grate 5 is the furnace 3, and the space below is the ash pit 6; the feeding system 14 includes an outer cylinder 17 and an auxiliary material cylinder 22, and the feeding system 14 passes through the whole The two side walls of the furnace 3 and the furnace body 2 extend out of the furnace body 2. The part of the wall of the outer cylinder 17 located in the furnace 3 is provided with a material outlet 13, and one end is provided with a mounting plate 31, and the other One end is provided with a connecting plate 23, and the inside is coaxially provided with a pusher s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com