an exhaust gas burner

A technology of waste gas combustion and waste gas, which is applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of complex manufacturing process, poor combustion effect, scattered structure, etc., achieve simple structure, reduce overall cost, and uniform temperature distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further described in conjunction with accompanying drawing:

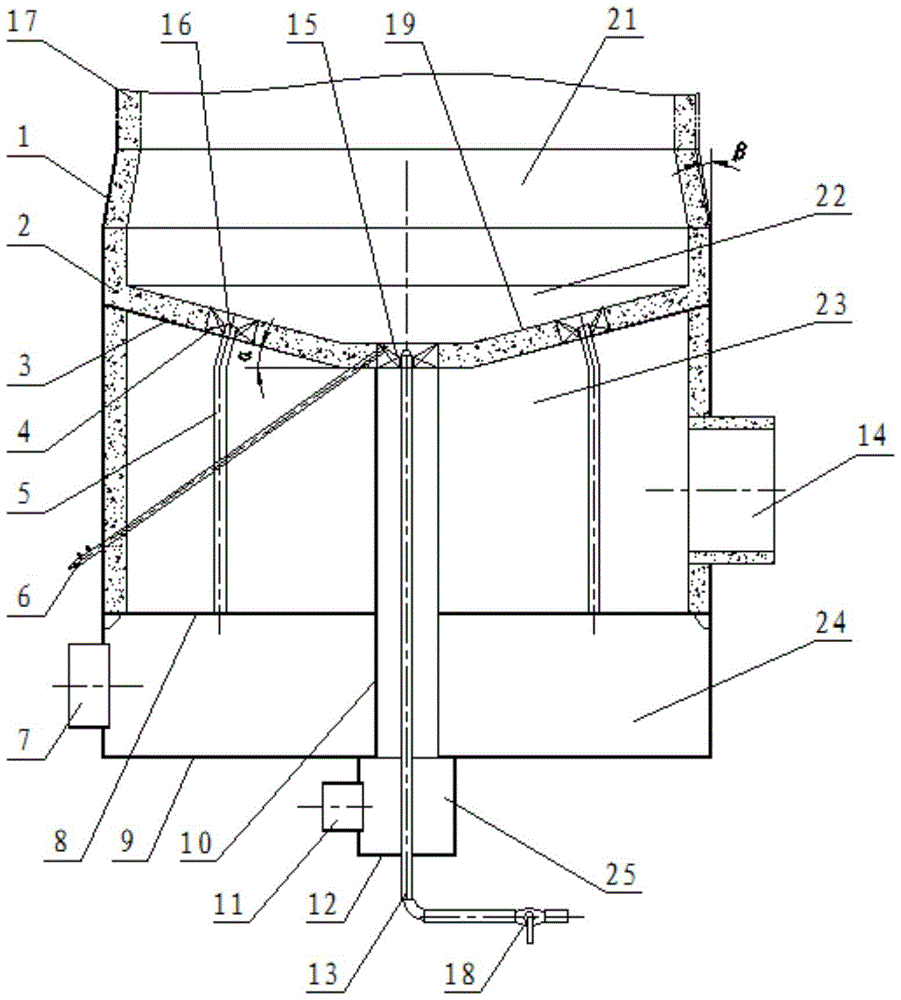

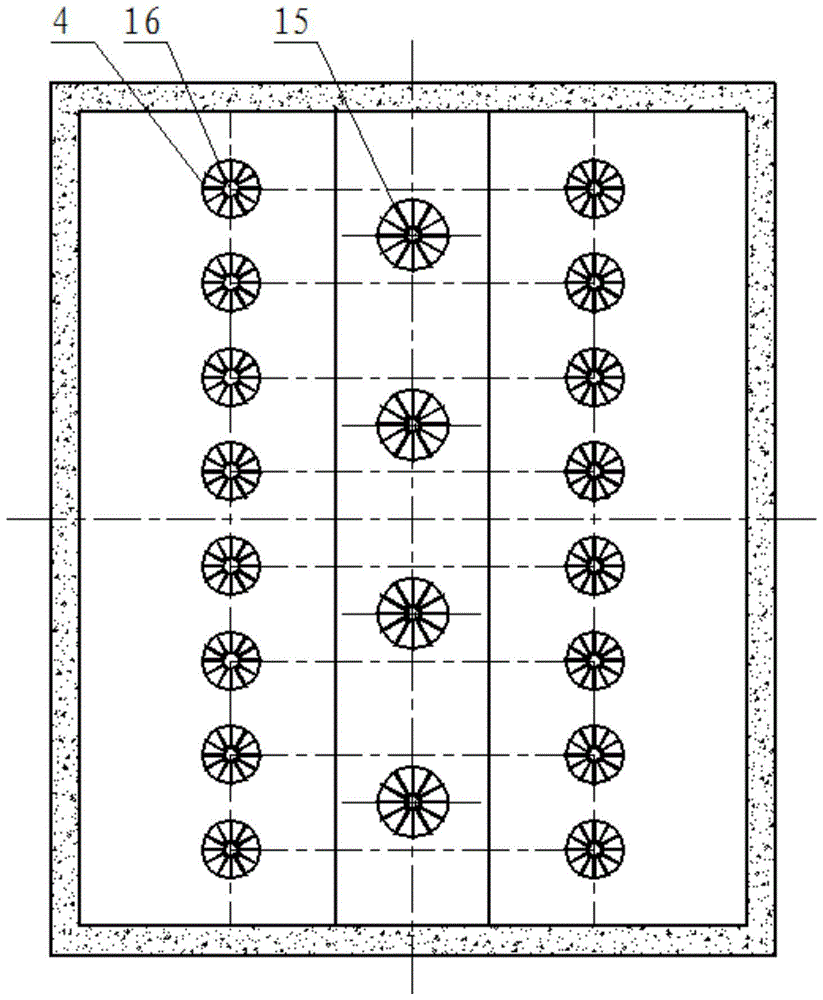

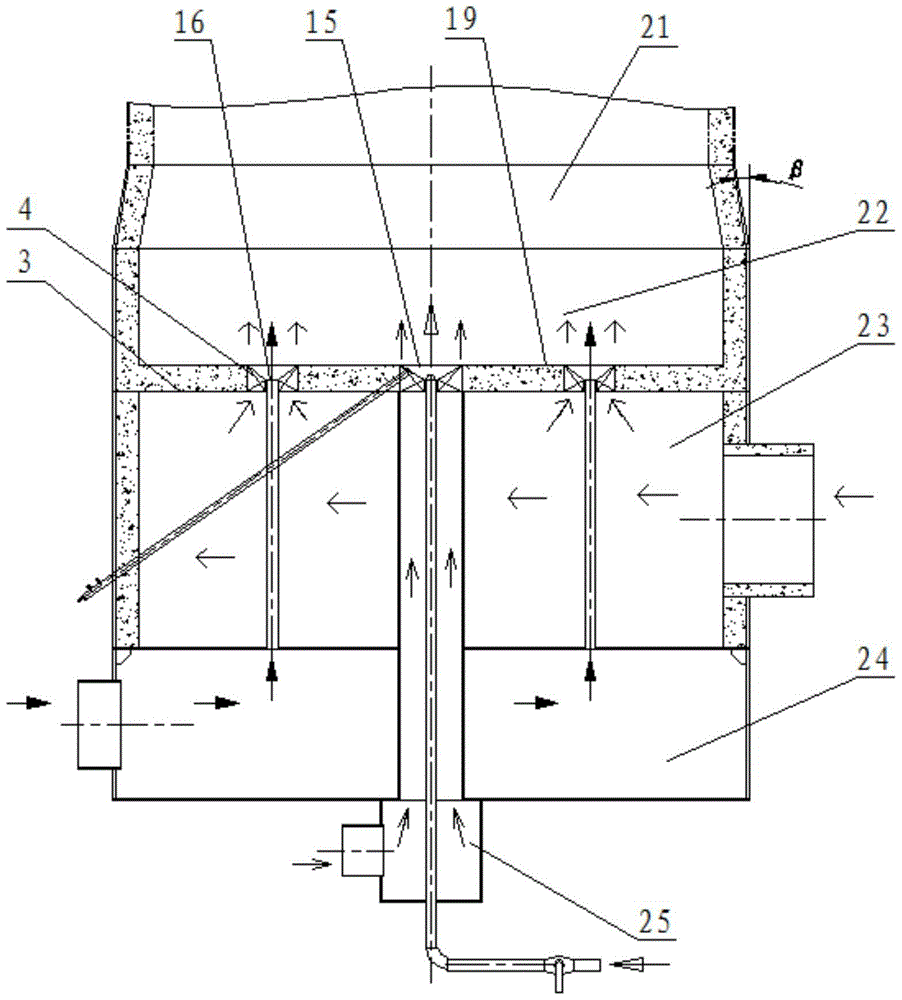

[0048] see Figure 1a , Figure 2a , Figure 3a , Figure 4a and Figure 5a , a waste gas burner, which is arranged at the lower part (or head) of the incinerator. All are provided with an independent ignition gun 6; from top to bottom, there are successively provided with an outlet contraction section 21, a combustion chamber 22, a distribution mixing plate 3, an exhaust gas collection cabin 23, an exhaust gas partition 8, a mixing air collection cabin 24, a mixing Air partition 9, combustion-supporting air assembly cabin 25; combustor combustion-supporting air outlet 15, exhaust gas outlet 4, and mixing air outlet 16 are reasonably distributed on the distribution mixing plate 3; each burner nozzle is provided with an independent fuel pipeline riser 13 And the valve 18; the burner is connected with the incinerator body 17 through the outlet contraction section 21.

[0049] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com