PVC (polyvinyl chloride) film transportation device of composite film laminating machine

A sending device and laminating machine technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of multi-power, consumption, etc., and achieve less joints of finished products, convenient roll change, and roll change frequency Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

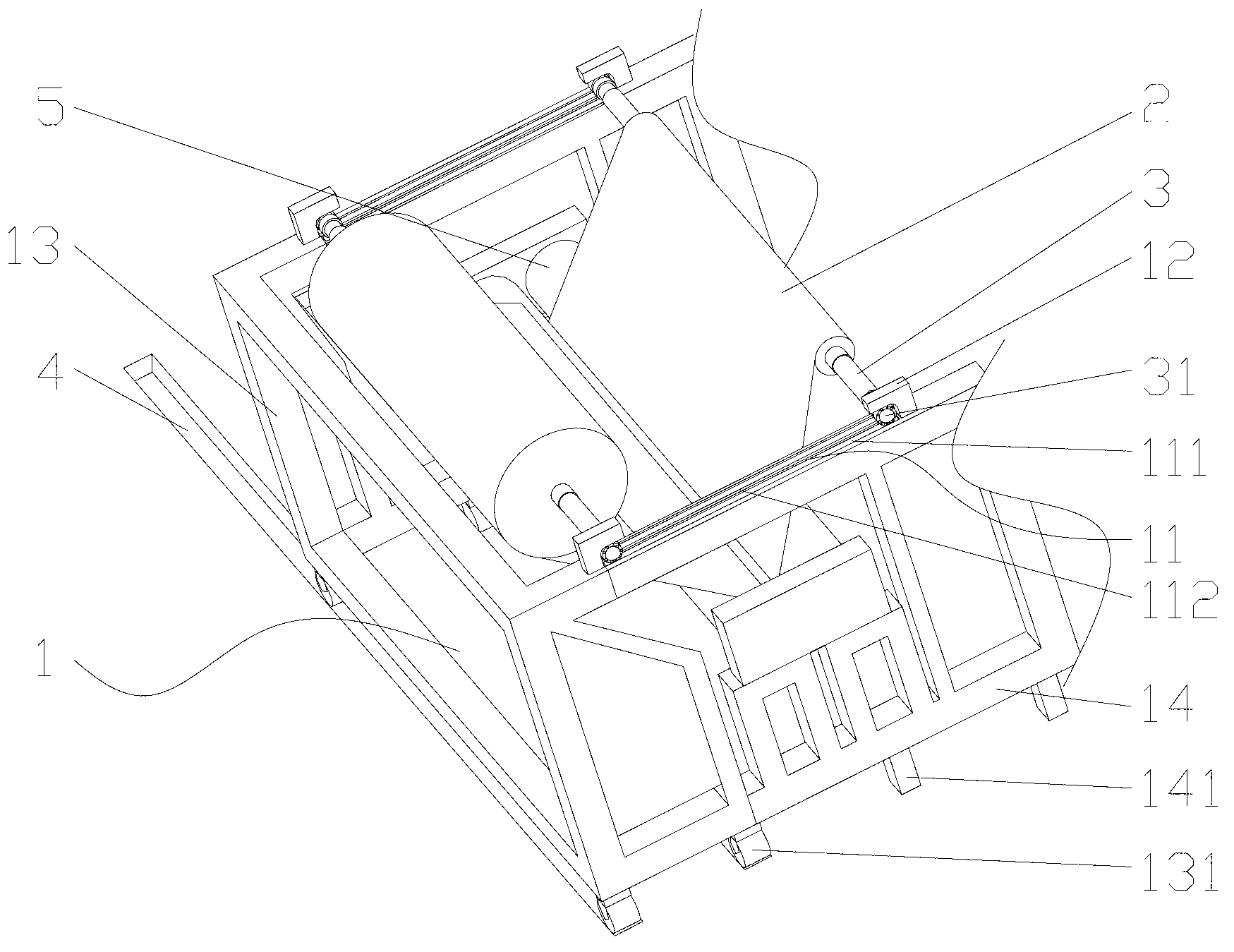

[0018] according to figure 1 As shown, the PVC film sending device of the composite film laminating machine of the present invention comprises a frame 1, and the two sides of the frame 1 are respectively provided with guide rails 11, and the two ends of the guide rail 11 are respectively provided with fixed mounts 12; The above-mentioned PVC film 2 is a roll shape, and the two ends of the PVC film 2 are respectively sleeved on the sending guide roller 3, integrated with the sending guide roller 3, and erected on the fixed frame 12 of the frame 1; the sending guide roller 3 Both ends are respectively provided with bearings 31 at the joints with the fixed frame 12 , and the guide rail 11 is provided with a bearing rolling guide groove 111 ; the bearings 31 roll along the bearing rolling guide grooves 111 or are fixed on the fixed frame 12 .

[0019] Further, the frame part 13 under the fixed frame 12 at one end is detachable from the guide rail 11 and the frame part 14 where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com