Hydraulic roll changing device for rolling mill work roller

A roll changing device and work roll technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of inconvenient access to rolling mill, large volume of forklift, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

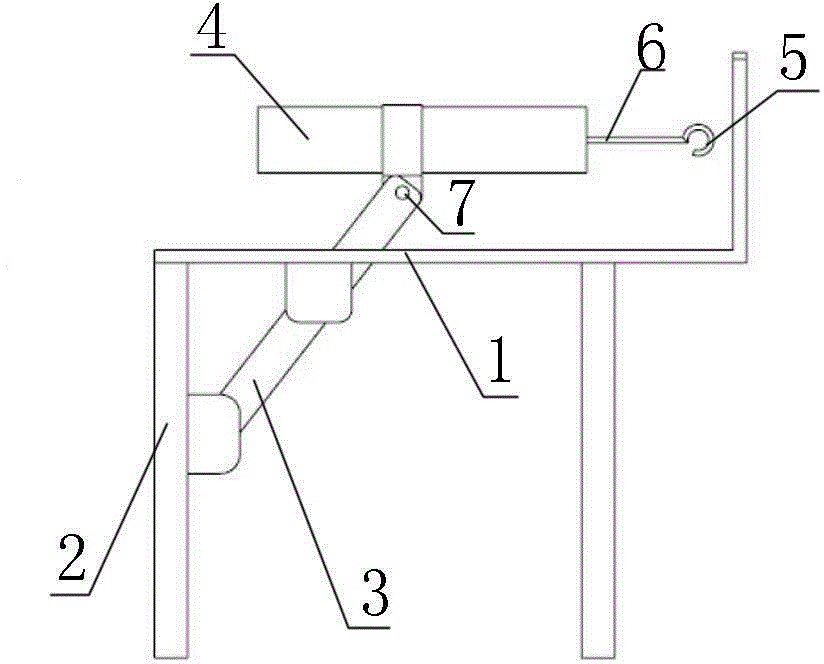

[0008] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a hydraulic roll changing device for the working rolls of the rolling mill according to the present invention includes a fixed frame 1 that can be placed at the front end of the working rolls of the rolling mill, and an outer wall 2 of the fixed frame 1 is hinged There is a hydraulic support rod 3 arranged obliquely upward, and a horizontally arranged hydraulic cylinder 4 is connected to the end of the hydraulic support rod 3. The end of the hydraulic cylinder 4 opposite to the work roll system of the rolling mill is connected to a Tie bar 6 with hook 5 for work rolls. As shown in the figure, the hydraulic cylinder 4 is horizontally arranged above the fixed frame 1 , and the lower part of it is hinged to the end of the hydraulic support rod 3 through the connecting end 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com