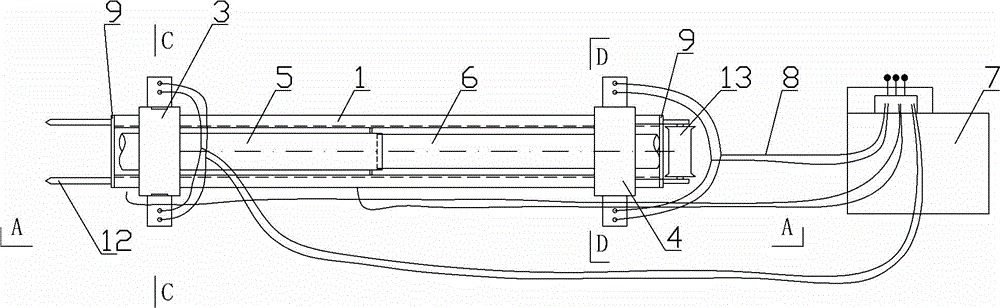

An anchor cable hydraulic automatic cable feeding device

An anchor cable, automatic technology, applied in the installation of anchor rods, mining equipment, earth-moving drilling, etc., can solve the problem of difficulty in entering the anchor cable, and achieve the effect of avoiding the anchor cable from falling out, the design structure is ingenious, and the operation is flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

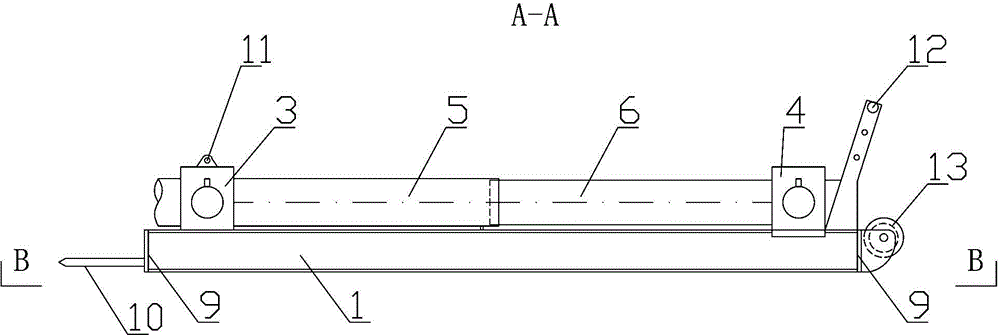

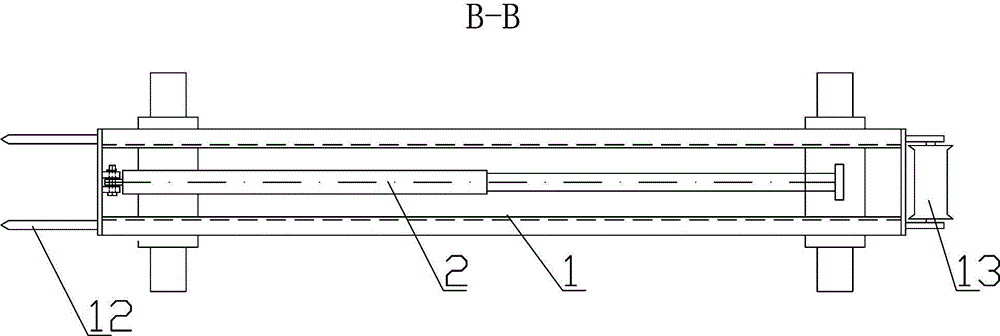

[0042] The more detailed use method and steps of the device of the present invention are as follows:

[0043] 1. Place the device on the ground, operate the control lever on the hydraulic pump station 7 to open the clips in the fixed clamping device 3 and the sliding clamping device 4, extend the telescopic cylinder 2, and move the sliding clamping device 4 to end of rack 1. Pass the anchor cable 14 through the pulley 13 in turn, slide the clamping device 4, the movable guide tube 6, the fixed guide tube 5 and the fixed clamping device 3, and pass through the fixed guide tube on the other side of the fixed clamping device 3.

[0044] Two, operate the control lever on the hydraulic pump station 7 to make the clips in the fixed clamping device 3 and the sliding clamping device 4 tighten the anchor cable 14 .

[0045] 3. Lift the device with a crane through the first lifting lug 11 and the second lifting lug 12, then slowly move to the opening of the anchor cable hole and align ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com