Roll changer of support roll

A roll changing device and support roll technology, which is applied in metal rolling, metal rolling racks, manufacturing tools, etc., can solve the problems of difficult safety hazards in roll changing, high roll changing efficiency, etc., and achieve low cost, simple operation, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

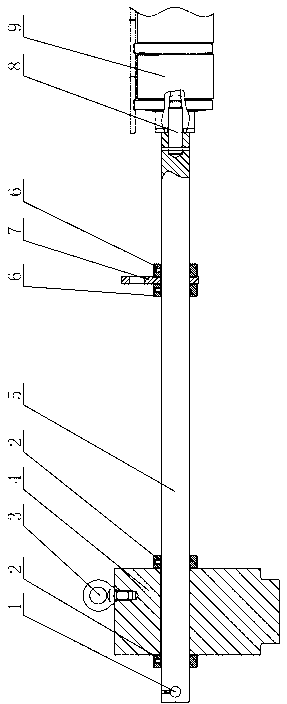

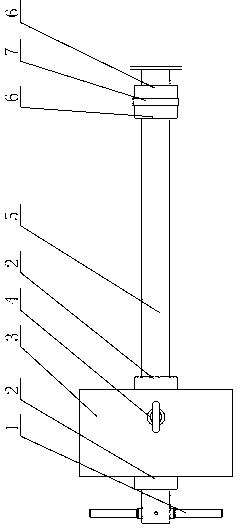

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 and figure 2 As shown, the support roll changing device of this embodiment includes a shaft 5, one end of the shaft 5 is connected to the support roll 9 through a connecting piece 8, a balance weight 4 is installed on the other end of the shaft 5, and the two ends of the balance weight 4 pass through the first A locking piece 2 is locked; the middle fulcrum of the shaft 5 is provided with a hanging part 7, and the two ends of the hanging part 7 are locked by the second locking piece 6. One side of the balance weight 4 is located on the shaft 5 and is equipped with a handle through a fastener 1. The handle 1 is convenient for workers to assist in operation; the upper part of the balance weight 4 is equipped with lifting lugs 3, which is convenient for lifting and installing.

[0015] The balance weight 4 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com