Device for drawing intermediate roll of eighteen-roll cold-rolling mill

A technology of intermediate rolls and cold rolling mills, which is applied in the direction of metal rolling stands, metal rolling mill stands, and metal rolling. Low cost, convenient roll replacement, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

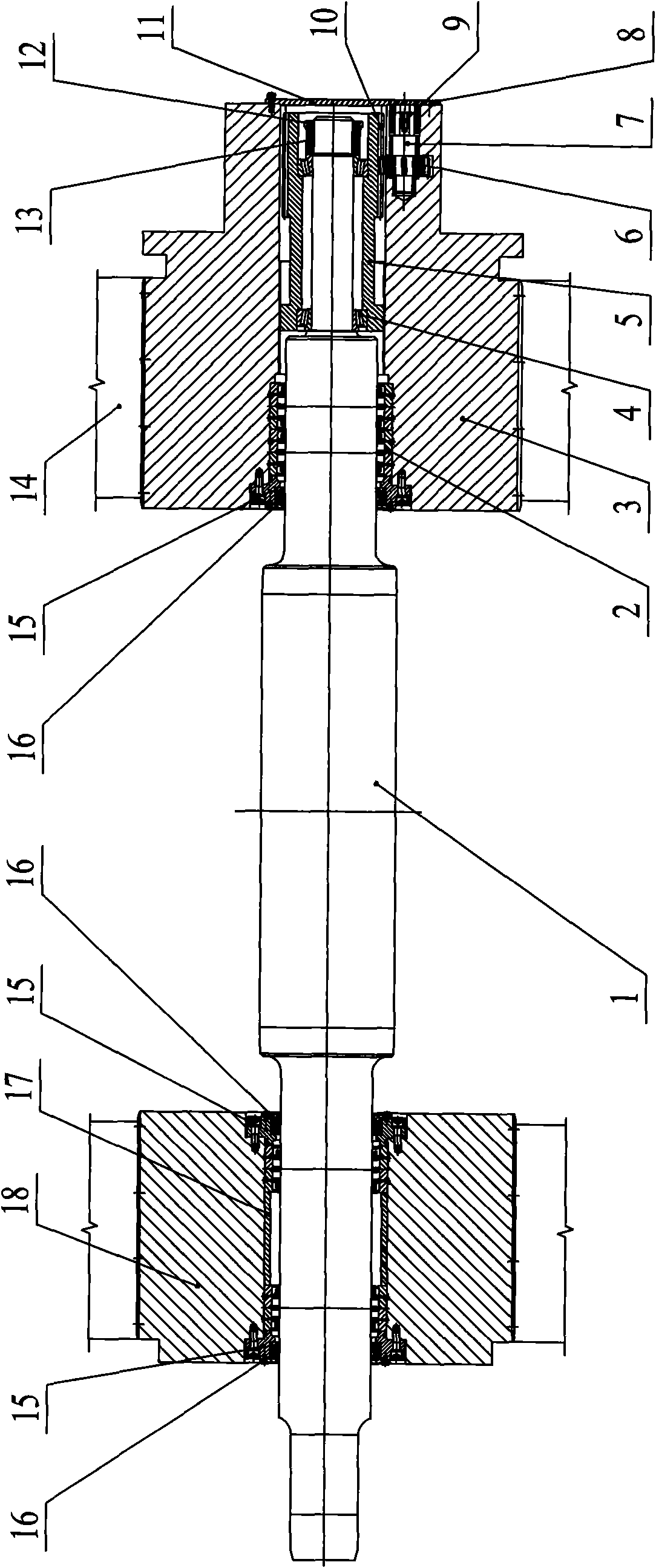

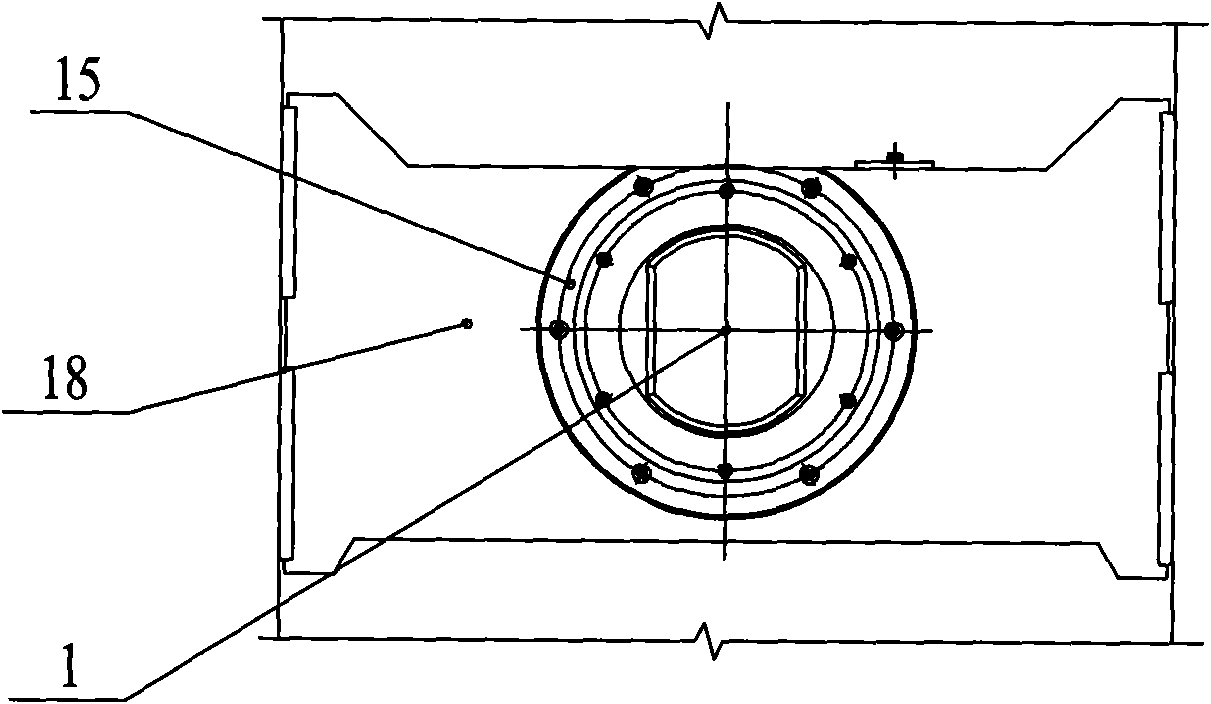

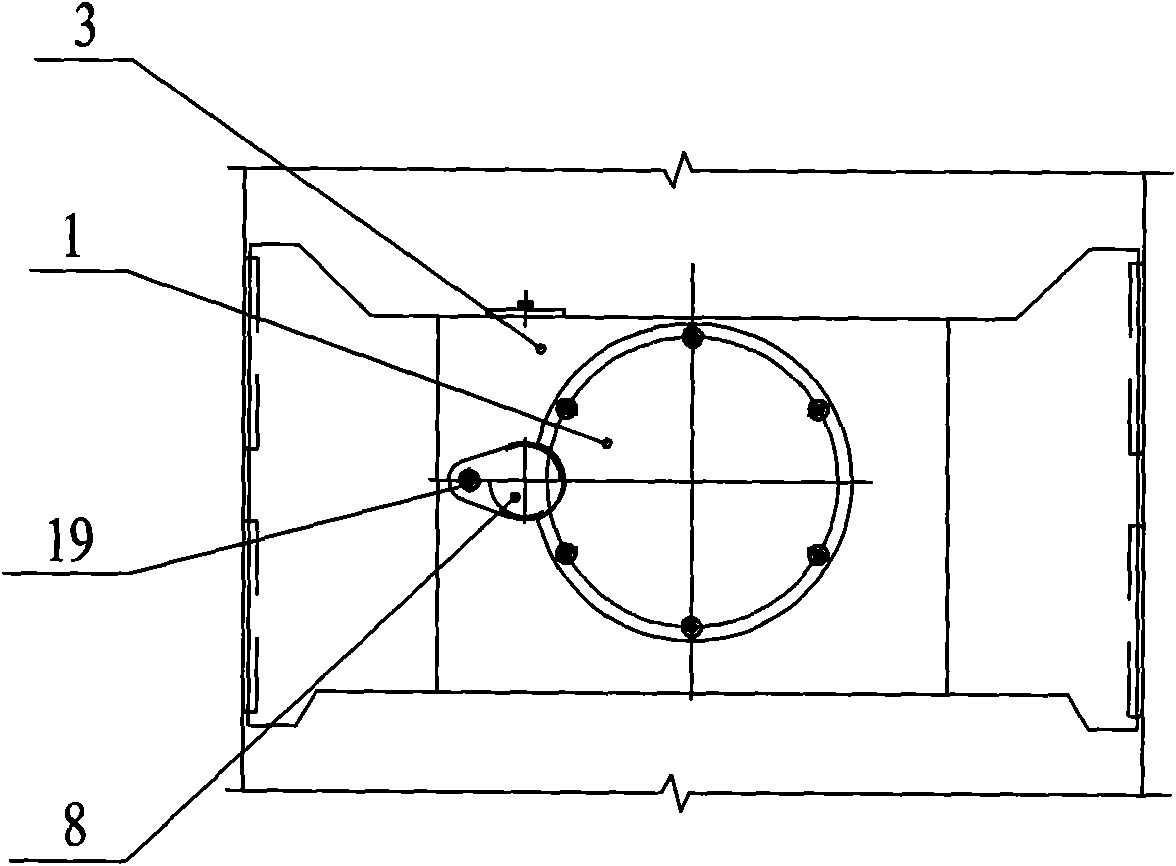

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0016] As shown in the figure, the present invention mainly consists of an intermediate roller 1, an intermediate roller bearing seat 2 on the operation side, an FC bearing without an inner ring 3, a tapered roller bearing 4, a threaded gear sleeve 5, a twitching gear 6, a twitching gear pin 7, a twitching gear Gear locking plate 8, end cover 11, nut 12, gland 13, rolling mill archway slideway 14, bearing end cover 15, sealing gasket 16, locking screw 19, spacer sleeve 17, drive side intermediate roll bearing housing 18 and other components are assembled. become.

[0017] Such as Figure 1 ~ Figure 3 As shown, the middle roller bearing housing 2 on the operation side and the middle roller bearing housing 18 on the driving side are respectively installed in the slideway 14 of the rolling mill archway in a conventional manner. Sliding up and down; the operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com