Single-sided continuous winding magnetron sputtering coating automatic production line for flexible substrate

A technology of magnetron sputtering coating and automatic production line, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., to achieve the effects of reducing labor, improving coating efficiency, and reducing waste of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

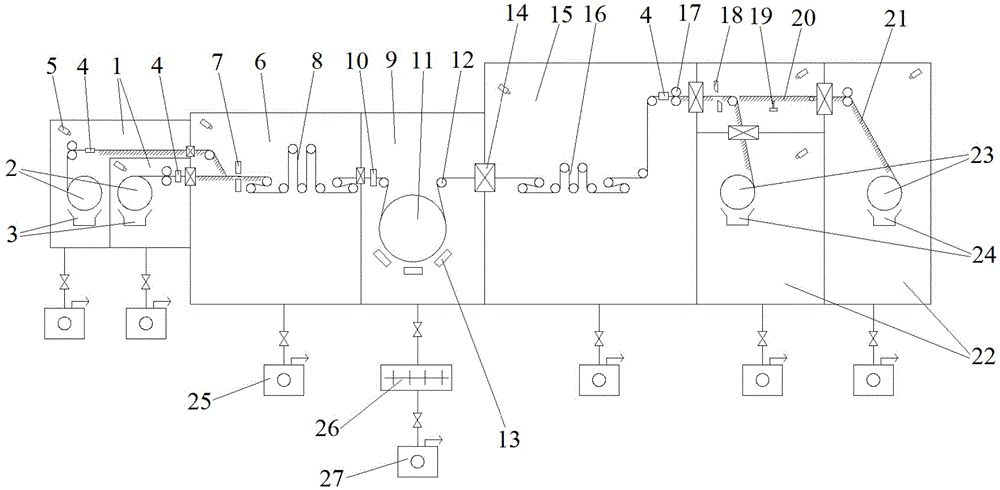

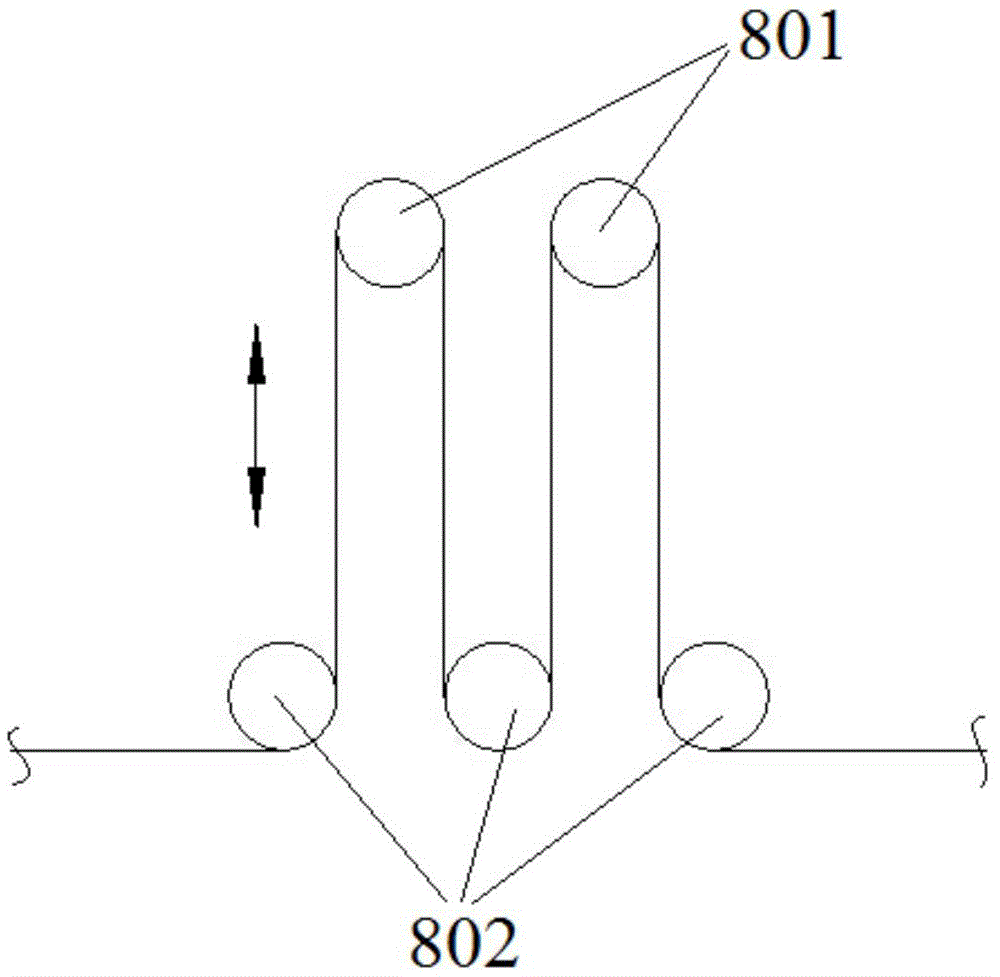

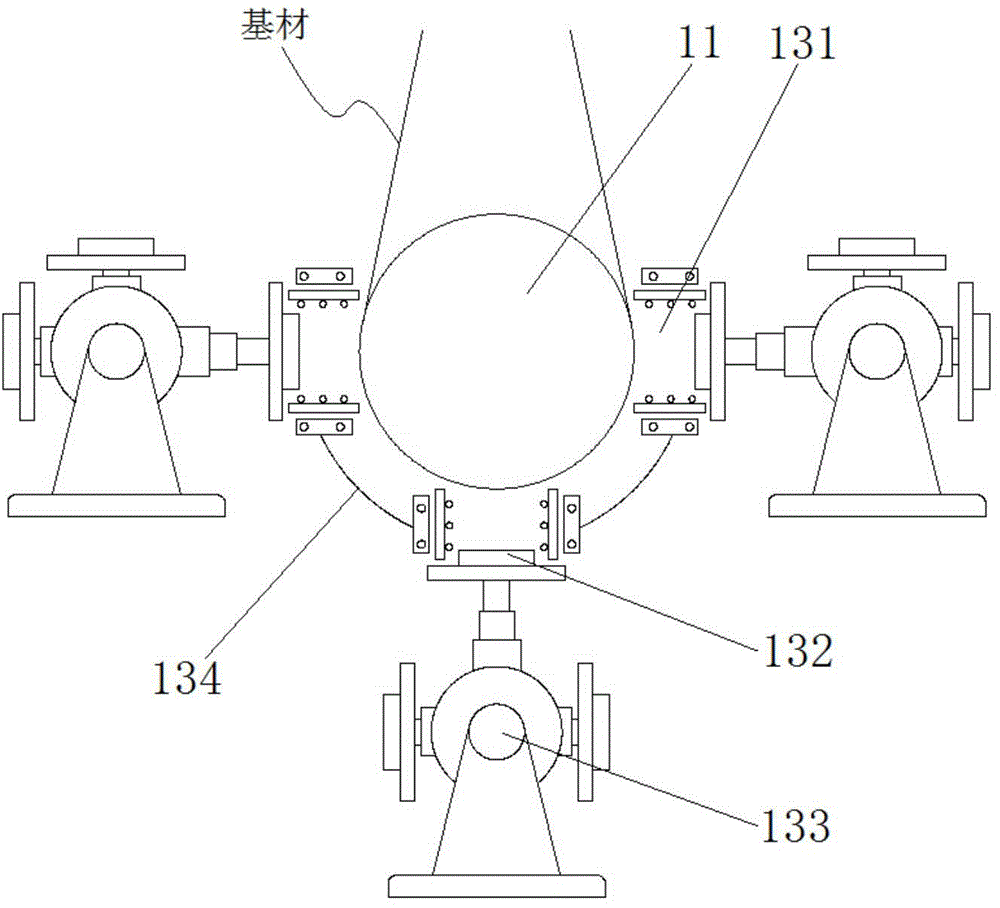

[0038] Combine figure 1 As shown, the flexible substrate single-side continuous winding magnetron sputtering coating automatic production line of this embodiment includes an uncoiling chamber 1, a winding chamber 22, and a coating vacuum chamber 9. The coating vacuum chamber 9 is equipped with a pre-processing mechanism 10. The cold roll 11 and one or more magnetron sputtering coating mechanism 13. Considering that traditional coating equipment can only coat one roll of substrate at a time, it is necessary to re-evacuate before coating another roll of substrate to reach the coating process conditions, which wastes a lot of time for roll changing and vacuuming, thereby reducing coating efficiency In this embodiment, the substrate to be coated and the roll to be reeled are prepared in advance, and the substrate to be coated and the roll to be reeled to reach the vacuum condition in advance, which solves the problem that traditional coating equipment cannot continuously coat multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com