Roll changing device for lithium battery pole piece coating machine

A coating machine, lithium battery technology, applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of loss of base material, downtime and replacement, reduce production efficiency, etc., to achieve convenient operation and ensure production efficiency , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

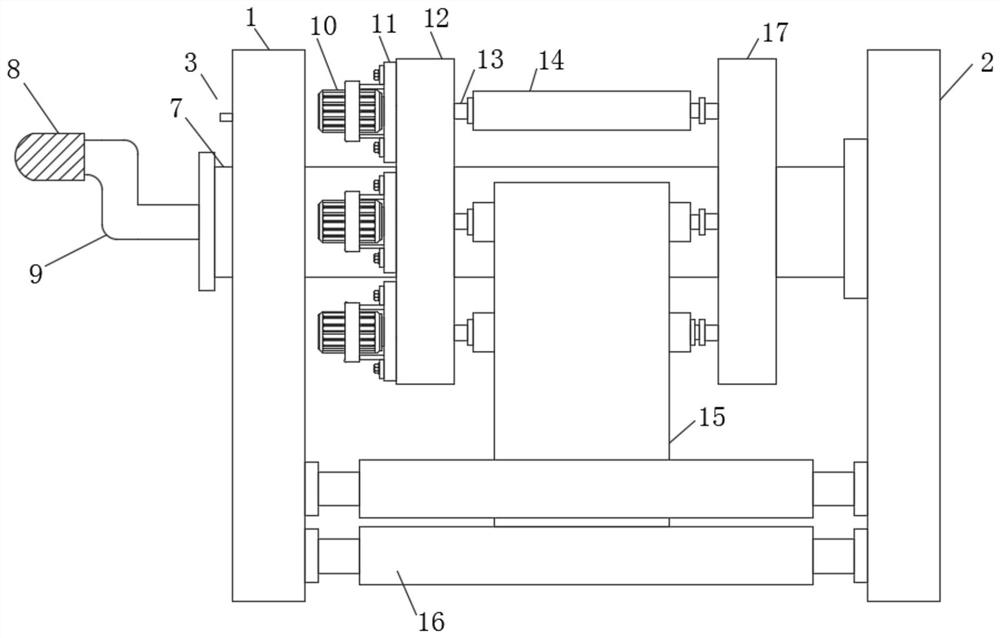

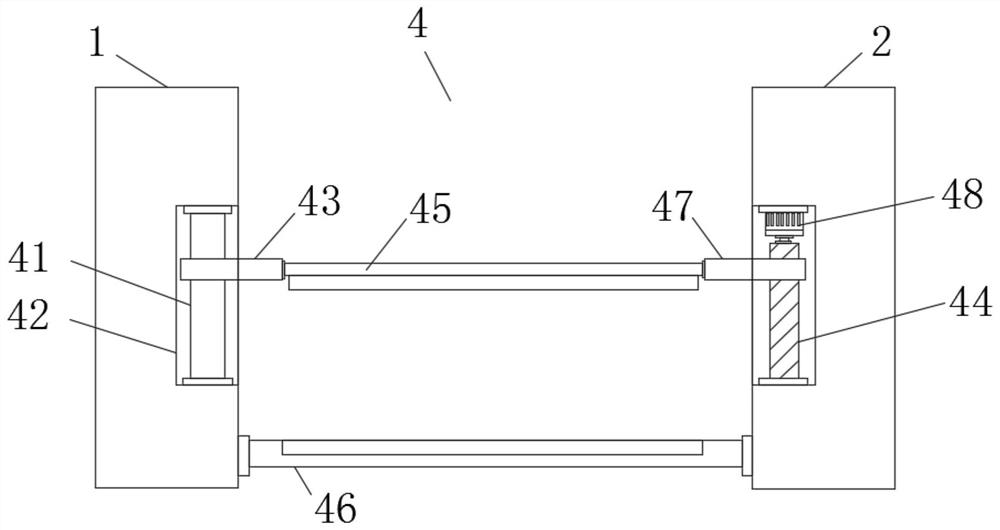

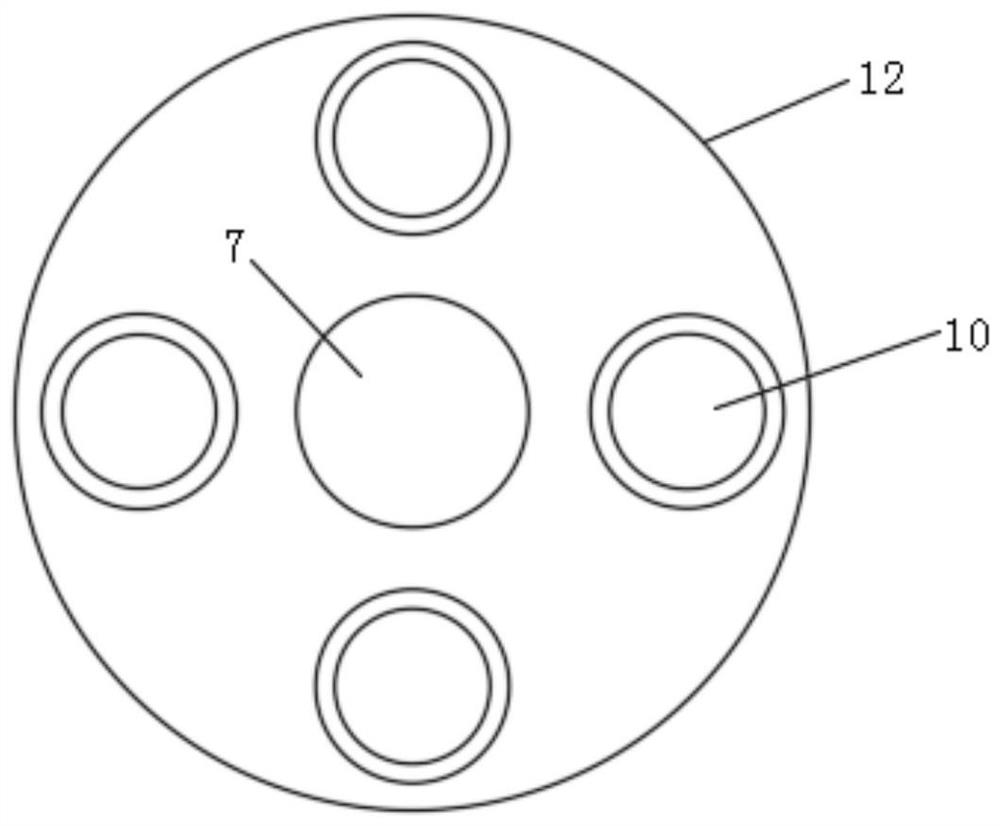

[0027] Example: such as Figure 1-8 As shown, a coil changing device for a lithium battery pole piece coating machine of the present invention includes a first support plate 1, a second support plate 2 and a base material 15. The first support plate 1 and the second support plate 2 There is a rotating rod 7 in between, the rotating rod 7 passes through the first support plate 1 through the opening 18, a limit mechanism 3 is arranged between the rotating rod 7 and the first support plate 1, and one end of the rotating rod 7 is connected to the second support plate 2 Rotational connection, the other end of the rotating rod 7 is fixedly connected with a rocking handle 9, the end of the rocking handle 9 away from the rotating rod 7 is covered with a rubber sleeve 8, and the outer side of the rotating rod 7 is symmetrically sheathed with a first fixed disc 12 and a second fixed plate 12 The fixed disc 17, the first fixed disc 12 and the second fixed disc 17 are all fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com