Frameless upright rolling mill with short stress trajectory

A short stress line, frameless technology, applied in the direction of metal rolling mill stands, metal rolling, metal rolling, etc., can solve the problems of reducing equipment work efficiency, frequent changes of rolling lines, and difficulty in mechanical processing, etc., and achieve processing operations And the effect of convenient roll change, light weight, and reduction of production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

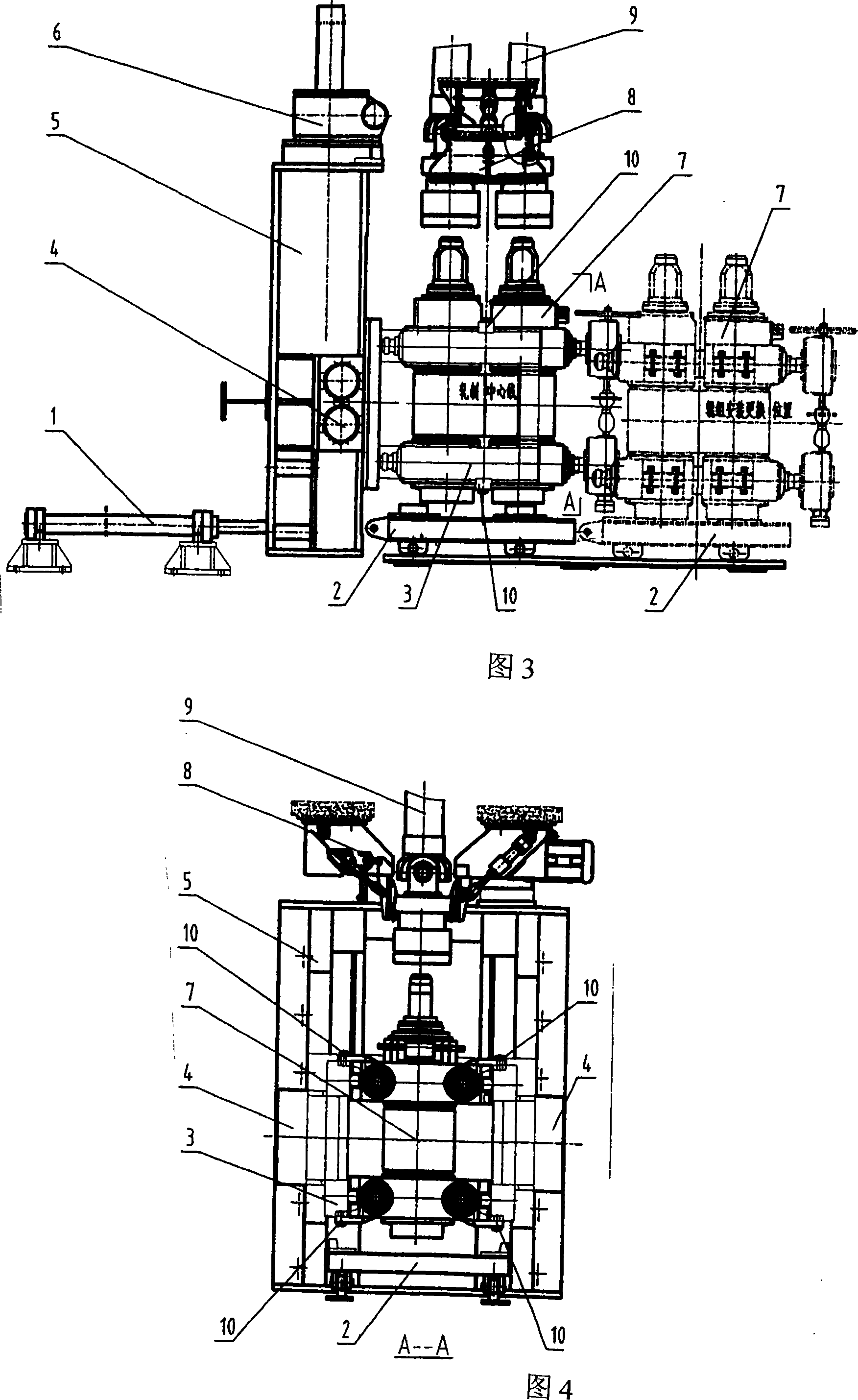

[0032] Roller group installation: put the roller group 7 on the roller changing trolley 2 (see Fig. 3, 4, 5, 6, 7), the roller changing hydraulic cylinder 1 works, and push the roller group 7 into the U-shaped bracket 3, consisting of One part in the groove rotation locking mechanism 10 --- the turning lug 13 is rotated into the groove of the U-shaped bracket 3, and the roller group 7 is fixed in the U-shaped bracket 3 with the connecting bolt 12; the worm gear lifter 6 works and the U-shaped After the bracket 3 and the roller group 7 are lifted to the working position, the rolling mill locking device 4 installed on the rolling mill base 5 is depressurized, and the piston rod 14 is pushed out by the elastic force of the disc spring 17, and the piston rod 14 locks the U-shaped bracket 3 On the rolling mill base 5 (see Figure 13).

[0033] Roll group replacement: Open the hydraulic control valve of the rolling mill locking device to retract the piston rod 14 in the rolling mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com