Vertical short stress path rolling mill without frame

A short stress line, frameless technology, applied in the direction of metal rolling mill stands, metal rolling, metal rolling, etc., can solve the problems of frequent rolling line changes, large processing volume, high cost, etc., to achieve processing operations and roll change Convenience, simple structure, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

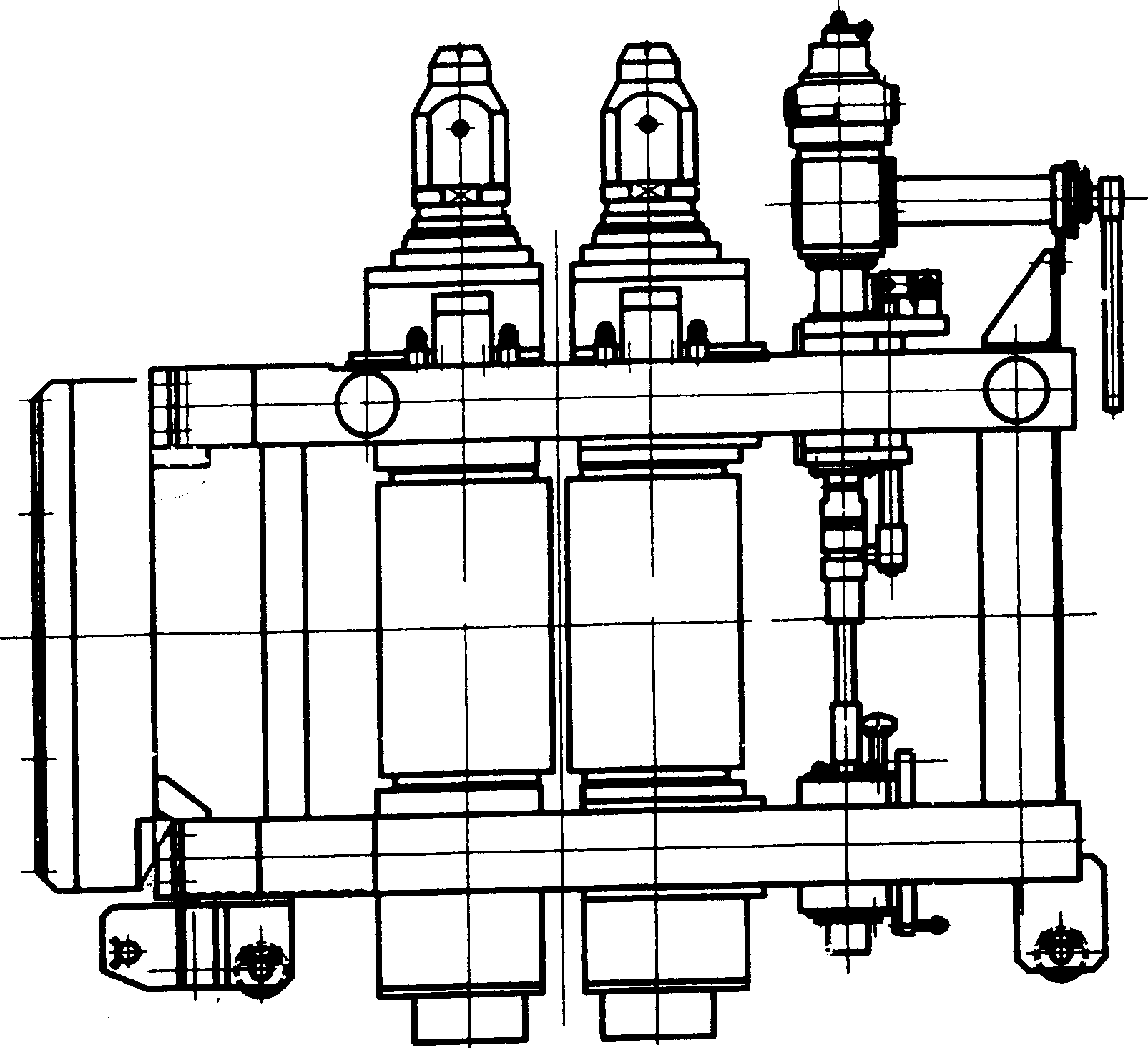

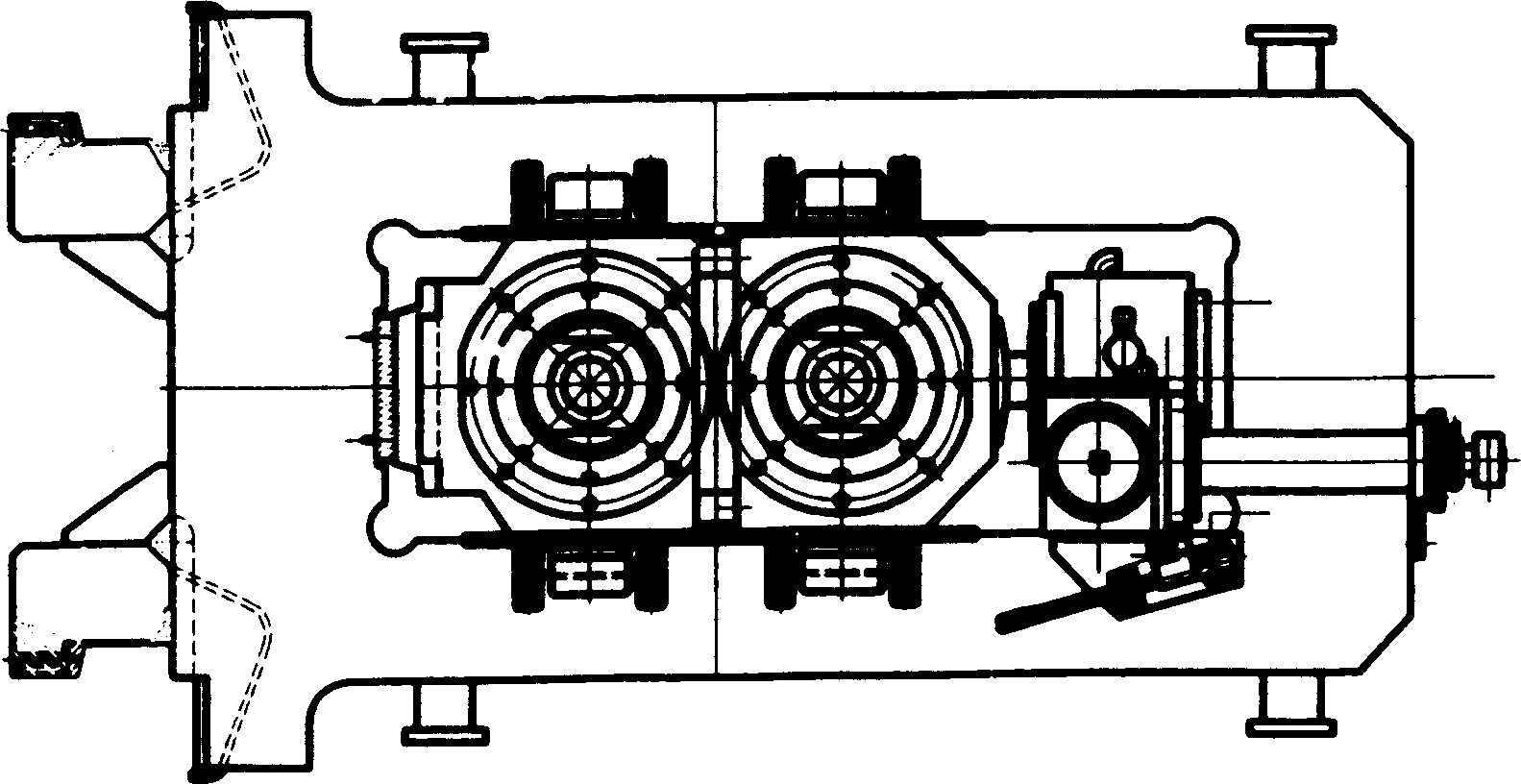

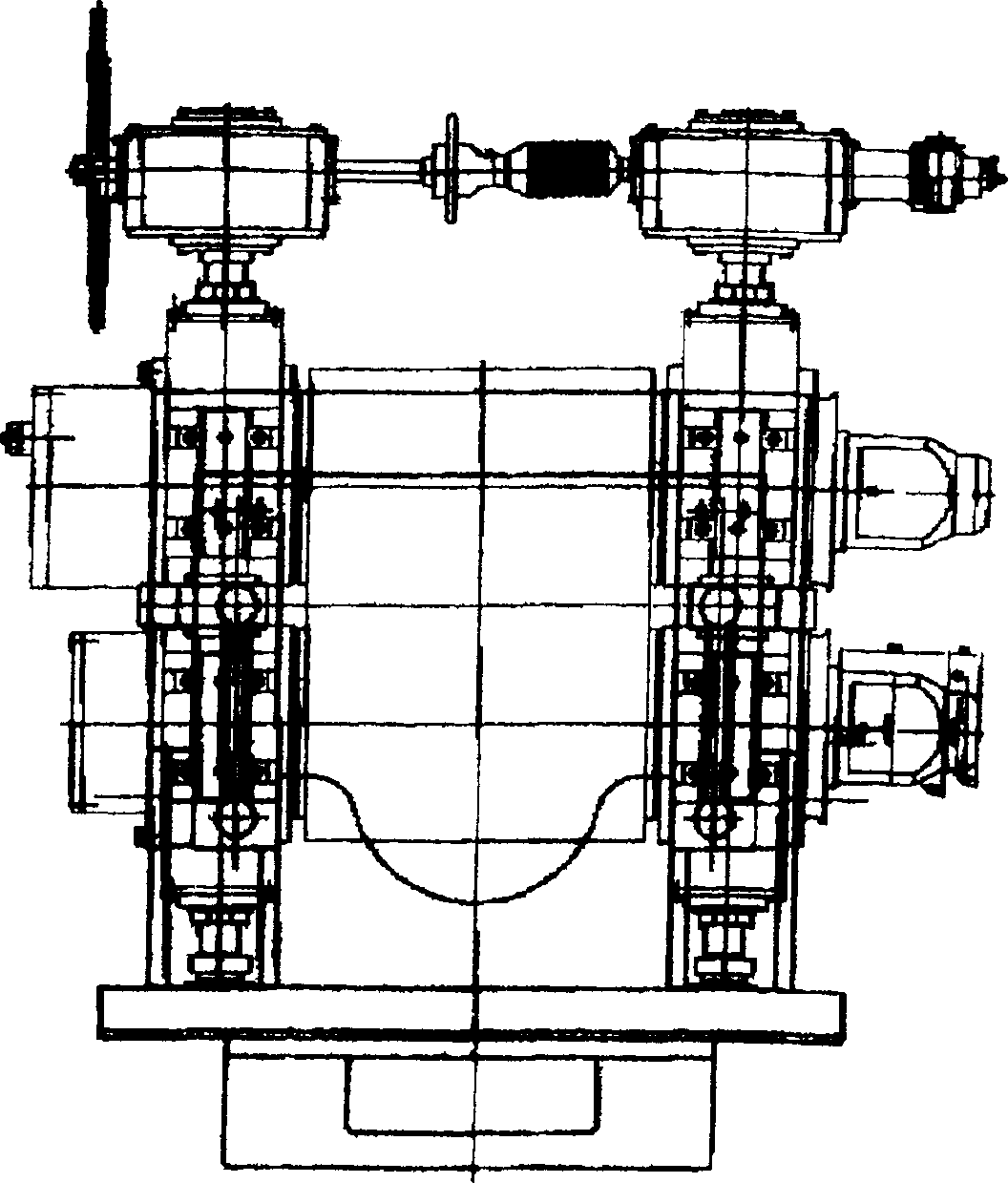

[0017] Roller group installation: Put the roller group 3 on the roller changing trolley 2, the roll changing hydraulic cylinder 1 works, push the roller group 3 into the U-shaped frame 7, turn the swivel 8 and the connecting bolt 9 and the U-shaped frame 7 to form a concave The groove rotates the locking mechanism 6 to fix the roll group 3 together (the effect of the turning ear prevents the roll system from jumping during the rolling process and ensures that the rolling line is fixed). Roller group replacement: Unscrew the connecting bolt 9, turn the swivel 8 to disengage from the U-shaped frame 7, and use the hydraulic cylinder to push out the roller group. The roller group and the U-shaped frame are locked on the column through the hydraulic cylinder (such as Figure 7 shown in 4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com