Method convenient for mounting roller mill transition guide plate

A technology for transitioning guide plates and guide plates, applied in the direction of guiding/positioning/aligning devices, etc., can solve the problems of inconvenient installation, difficult measurement and control of dimension A, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

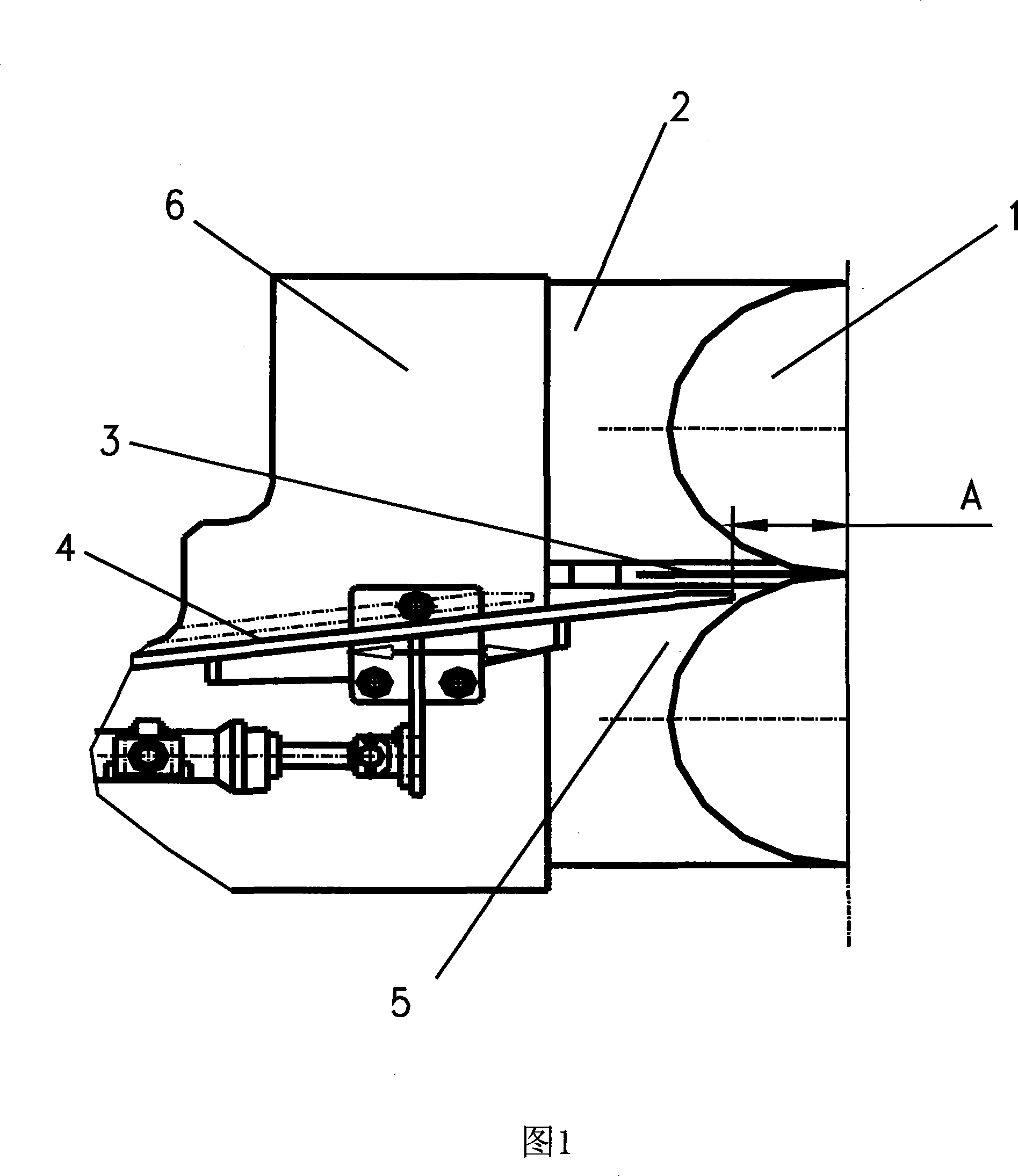

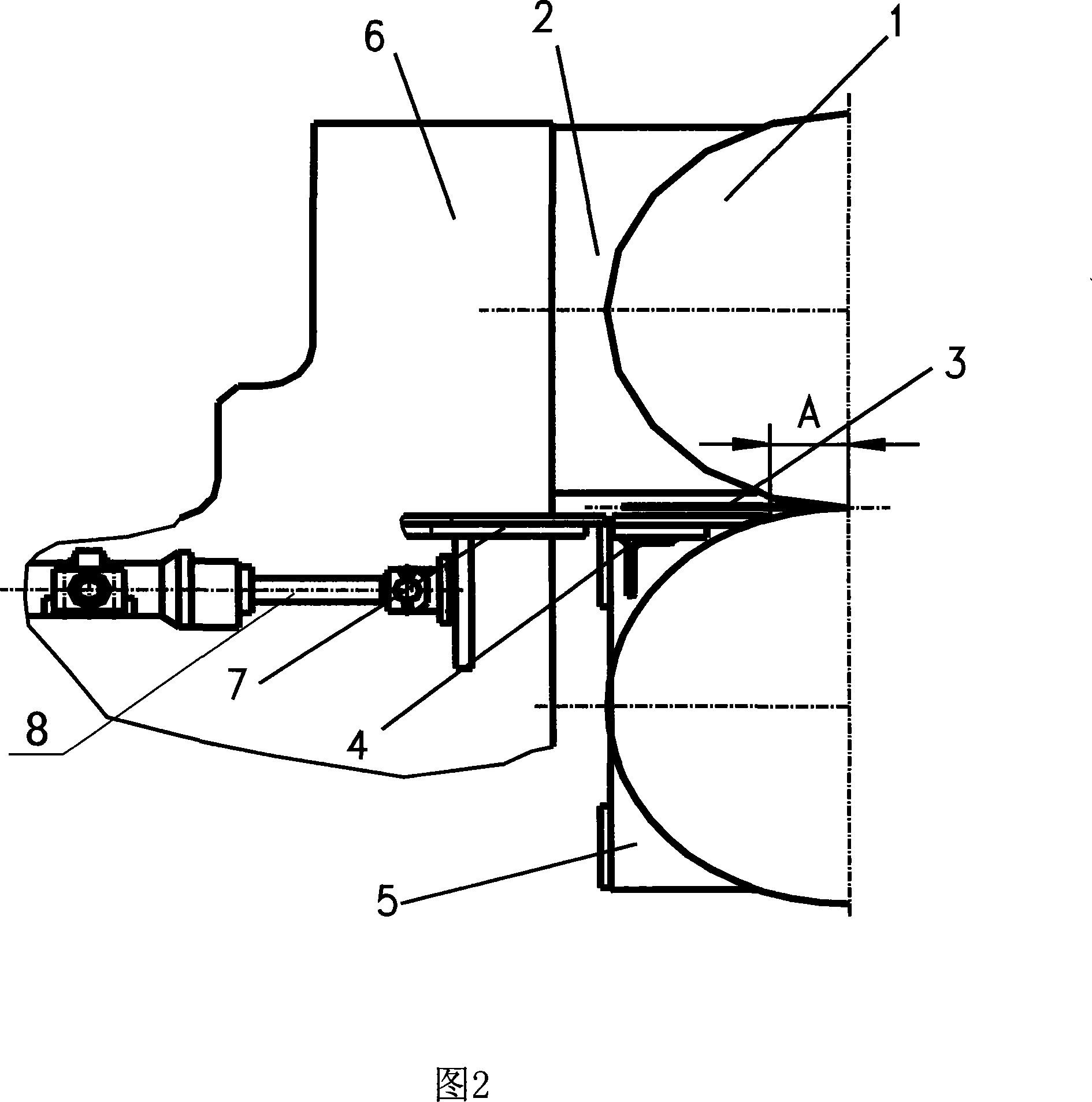

[0011] As shown in Figure 2: This method is convenient for installing the transition guide plate of the rolling mill, including two parts: the fixed guide plate (4) and the movable guide plate (7). According to the design dimension A, the fixed guide plate (4) is fixed on a pair of work rolls ( 1) On the lower bearing seat (5), it is easy to meet and control the technical requirement parameter A. The movable transition guide plate (7) of the adjacent part is horizontally fixed on the machine rear frame (6), and the machine rear frame is fixed on the hydraulic rod (8) of the hydraulic cylinder to meet the mobile requirements in the design.

[0012] When in use, after the aluminum plate is rolled by a pair of work rolls (1), the transition is assisted by the guide of the fixed guide plate (4) and the movable guide plate (7) in the adjacent part to ensure the smooth transition of the material head; During rolling, the movable guide plate part (7) moves in, and Fig. 2 shows that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com