Rapid roller changing device for upper roller on welding and rolling machine

A technology of roll changing device and rolling mill, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., and can solve the problem of unreasonable roll stand structure, poor upper roll installation accuracy, and poor precision reproducibility Good and other problems, to achieve the effect of compact structure, convenient roll change, time-saving and labor-saving use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

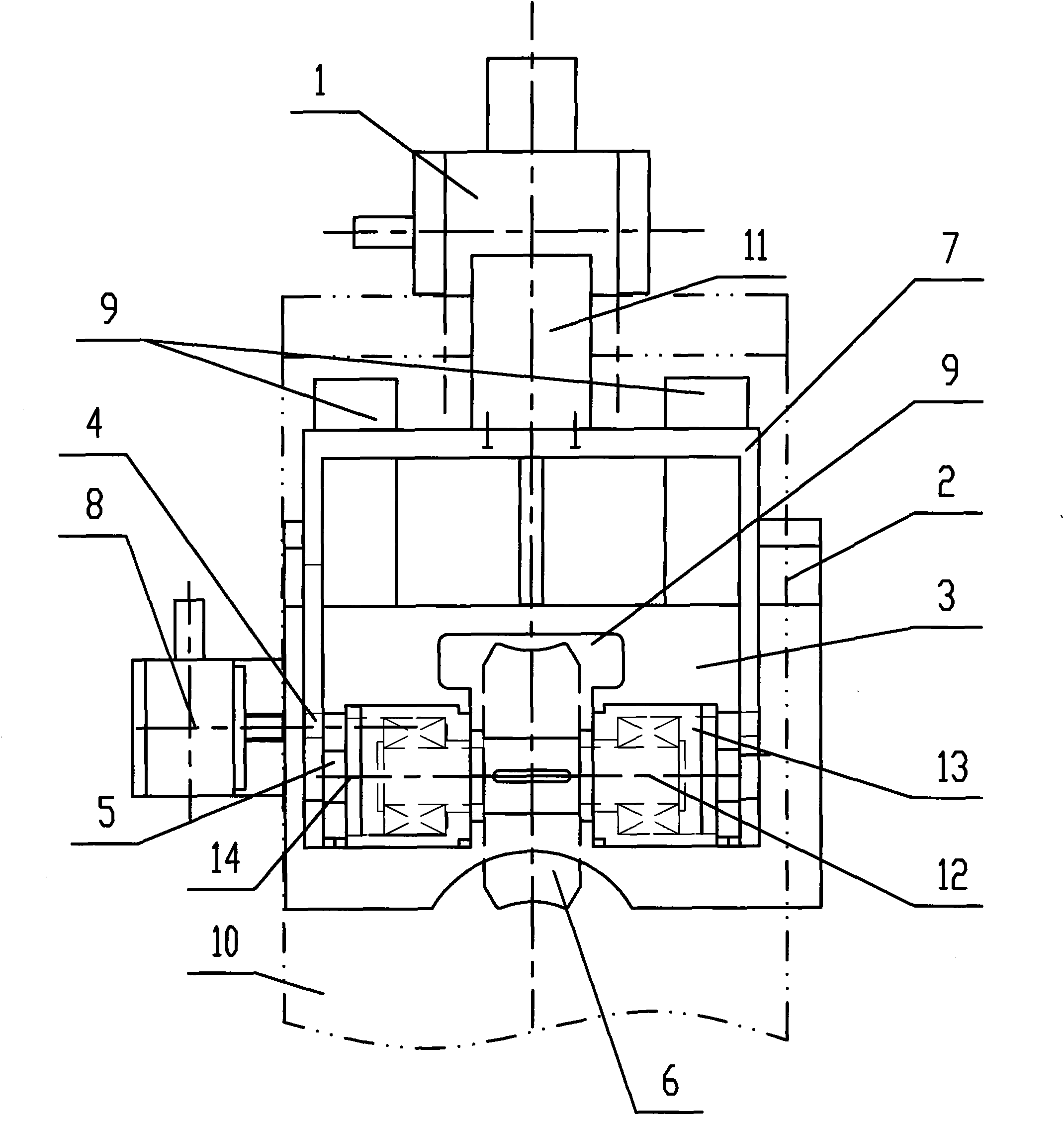

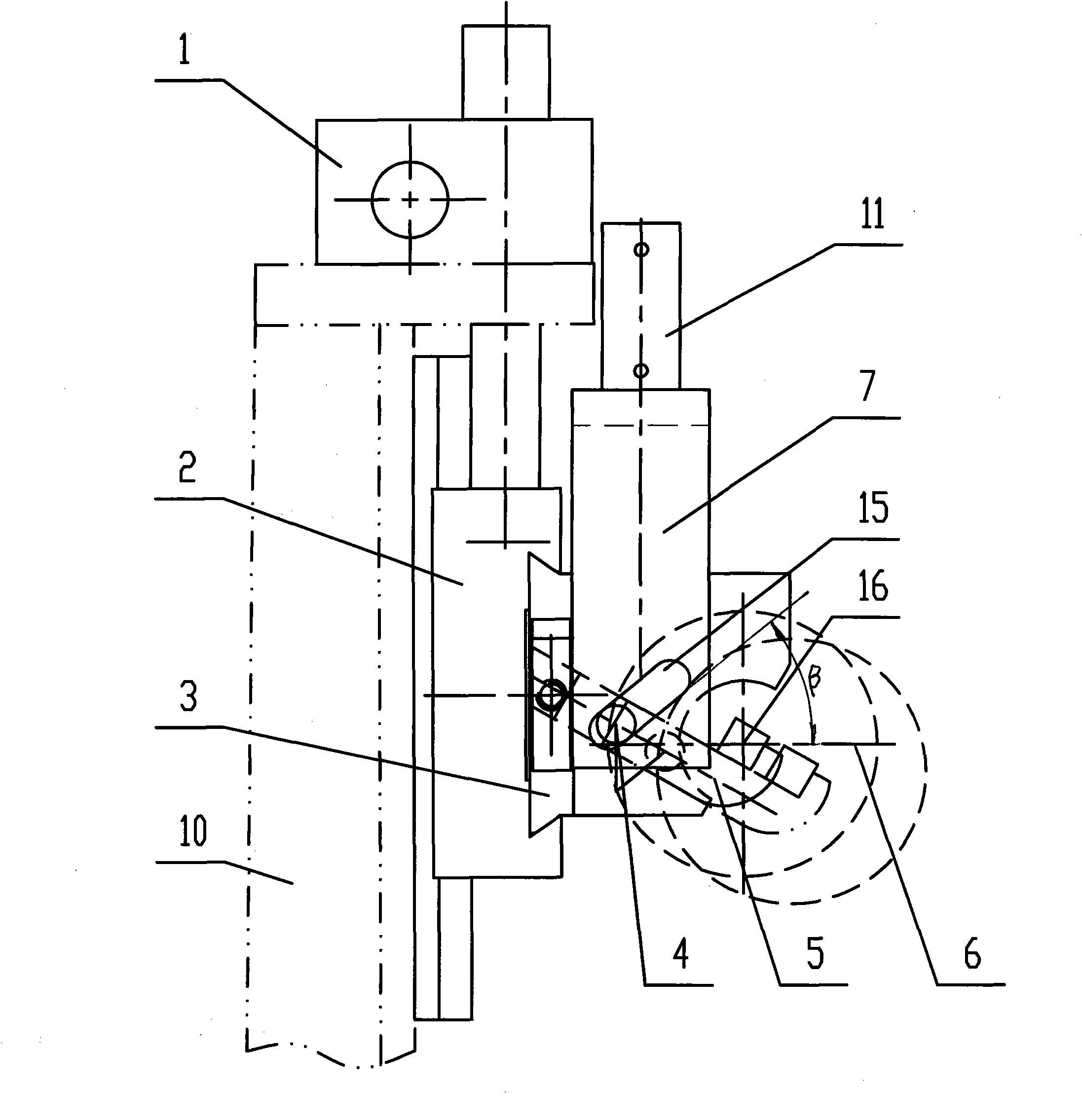

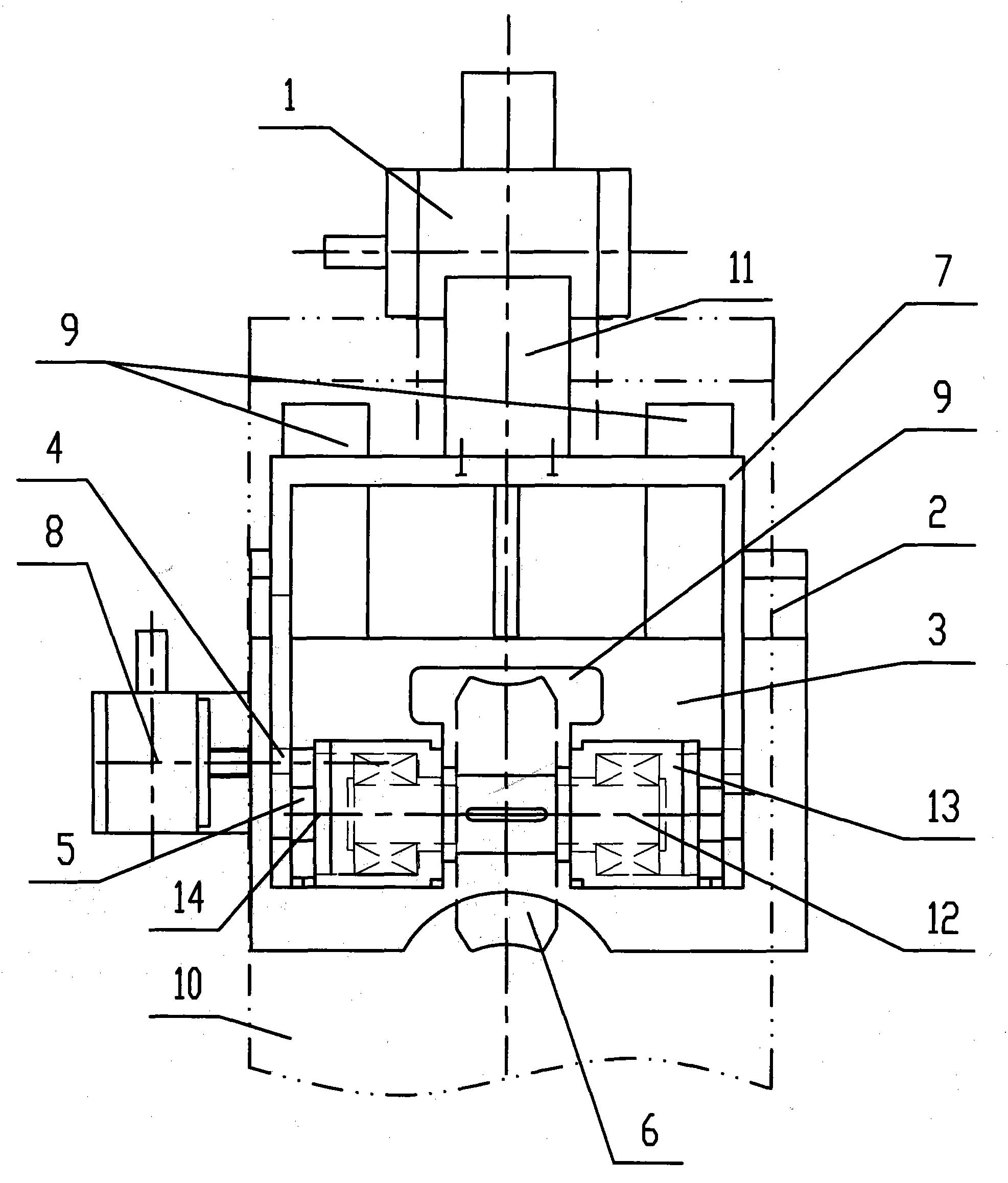

[0021] figure 1 , 2 Shown is a specific embodiment of the present invention, which is a quick roll change device for the upper roll of the welding roll mill installed on the ∮76mm stainless steel pipe welding mill; its structure includes a frame 10, a lifting mechanism 1 that drives up and down sliding The vertical slide plate 2 and the upper roller are characterized in that: a roller seat 3 driven by a manual power source 8 and sliding horizontally is installed on the outer surface of the vertical slide plate 2, and the cover on both sides and the top of the roll seat 3 is covered by a cylinder 11 The gantry-type push frame 7 that drives up and down motion has two grooves 15 symmetrically processed in the two sides of the bottom of the push frame 7. Each of the grooves 15 is inclined from the upper outside to the lower inside. The horizontal angle β formed by the groove 15 and the diameter of the upper roller 6 is 30°; the upper roller cavity 9 with an open bottom is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com