Control method for flying shear tail-shearing of rod wire

A control method, bar and wire rod technology, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of unable to complete the shearing normally, shorten the construction period, etc., and achieve stable and reliable shearing, shorten the construction period, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

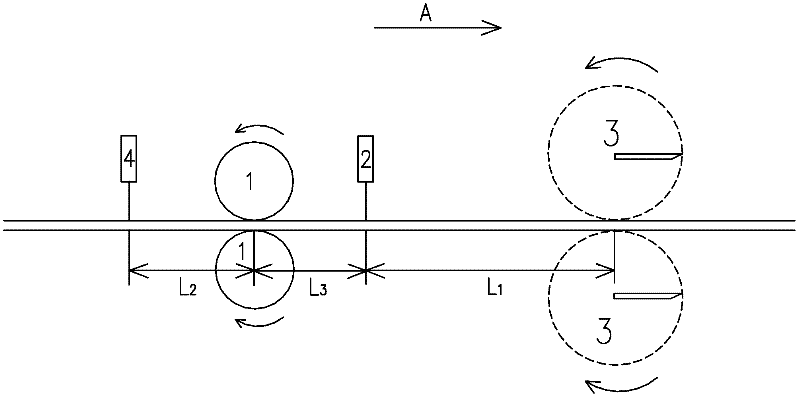

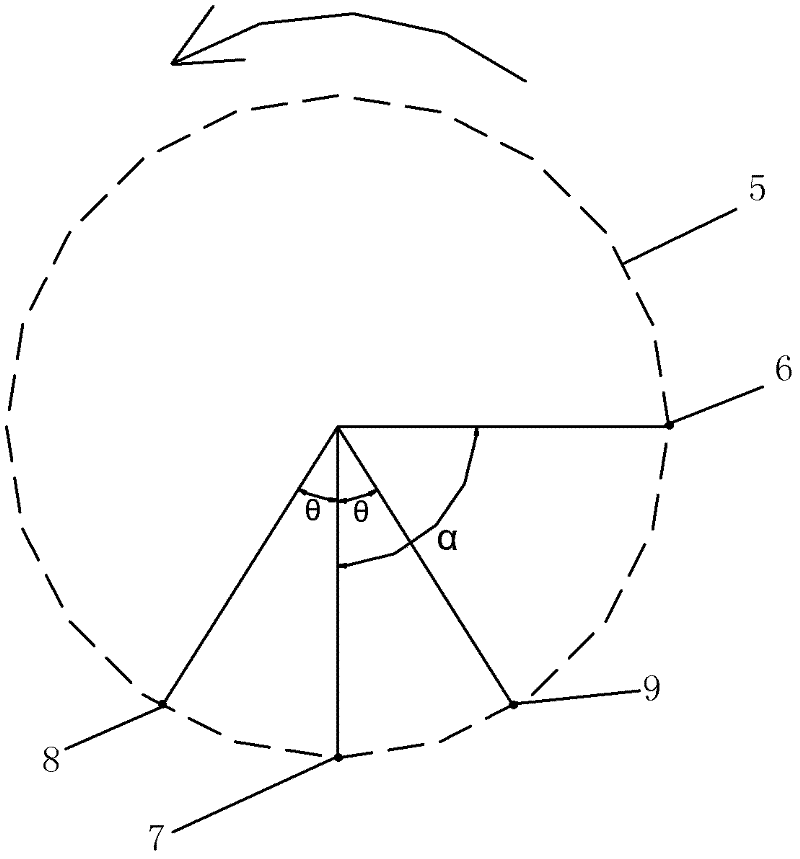

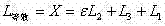

[0035] The rod and wire flying shears tail cutting control method provided by the present invention is an advanced electrical control method for rods and wires flying shears, specifically: through precise cutting edge position control, precise tail length control, second hot metal detector The conversion of the equivalent distance to the center line of the flying shear, the actual measurement and compensation of the elongation of the upstream rolling mill are combined to realize the short distance from the flying shear of the rod and wire to the first hot metal detector to the center line of the flying shear Timed tail-cutting control.

[0036] The tail cutting control method of the rod and wire provided by the invention comprises the steps of:

[0037] 1. Precise cutting edge position control

[0038] 1. An absolute encoder is installed at the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com