Lubricating method for rolling of stainless steel products on tandem cold rolling mill

A cold rolling mill, stainless steel technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

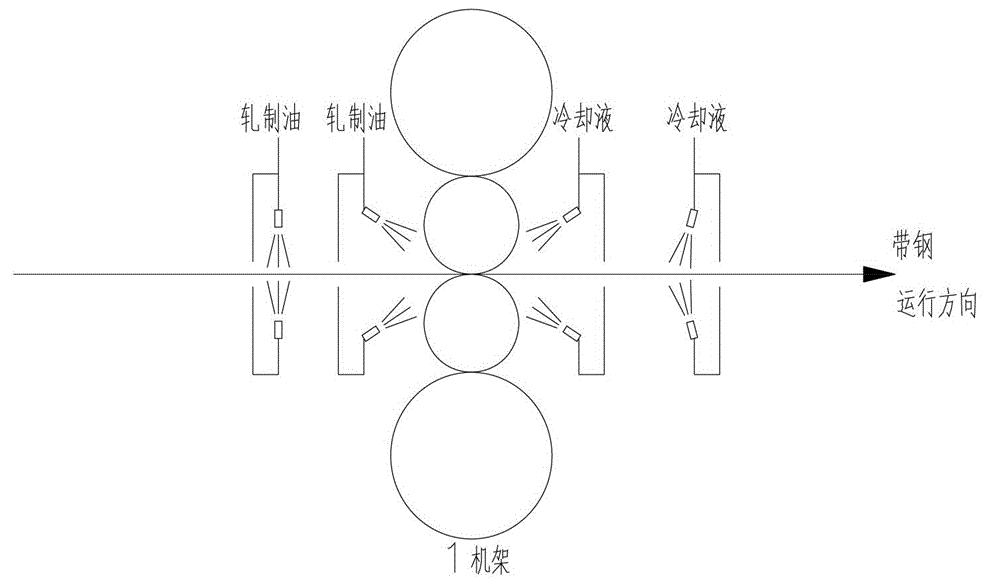

[0060] When producing SUS430 stainless steel, the width of the inlet strip is 1250mm, the thickness of the inlet strip is 3.0mm, and the thickness of the outlet is 0.9mm. According to the spirit of the present invention, the emulsion tank is used for lubrication of rolling mills with 2 to 4 stands and cooling for 1 and 5 stands. The emulsion concentration is 2.8%, the temperature is 55°C, and the injection pressure is 7.0 bar.

[0061] At the same time, there is a pump P at the outlet of the rolling oil tank 1 The rolling crude oil is delivered to the rolling oil injection pipeline in front of the 1st and 5th stands. The rolling oil injection branch pipe has a valve to control the delivery flow of the rolling oil. The injection pressure of the rolling oil is 5.5bar and the temperature of the rolling oil At 75℃, the injection volume of rolling oil at the inlet is calculated as follows:

[0062] Material: SUH430, mill entrance thickness: 3.00mm, mill exit thickness: 0.90mm, strip wid...

Embodiment 2

[0066] When producing SUS430 stainless steel, the width of the inlet strip is 1250mm, the thickness of the inlet strip is 2.89mm, and the thickness of the outlet is 0.50mm. According to the spirit of the present invention, the emulsion tank is used for lubrication of rolling mills with 2 to 4 stands and cooling for 1 and 5 stands. The emulsion concentration is 2.8%, the temperature is 55°C, and the injection pressure is 7.0 bar.

[0067] At the same time, there is a pump P at the outlet of the rolling oil tank 1 The rolling crude oil is delivered to the rolling oil injection pipeline in front of the 1st and 5th stands. The rolling oil injection branch pipe has a valve to control the delivery flow of the rolling oil. The injection pressure of the rolling oil is 5.5bar and the temperature of the rolling oil At 75℃, the injection volume of rolling oil at the inlet is calculated as follows:

[0068] Material: SUH430, mill entrance thickness: 2.89mm, mill exit thickness: 0.50mm, strip w...

Embodiment 3

[0072] When producing SUS409L stainless steel, the width of the inlet strip is 1250mm, the thickness of the inlet strip is 2.91mm, and the thickness of the outlet is 0.66mm. According to the spirit of the present invention, the emulsion tank is used for lubrication of rolling mills with 2 to 4 stands and cooling for 1 and 5 stands. The emulsion concentration is 2.8%, the temperature is 55°C, and the injection pressure is 7.0 bar.

[0073] At the same time, there is a pump P at the outlet of the rolling oil tank 1 The rolling crude oil is delivered to the rolling oil injection pipeline in front of the 1st and 5th stands. The rolling oil injection branch pipe has a valve to control the delivery flow of the rolling oil. The injection pressure of the rolling oil is 5.5bar and the temperature of the rolling oil At 75℃, the injection volume of rolling oil at the inlet is calculated as follows:

[0074] Material: SUH409L, rolling mill entrance thickness: 2.91mm, rolling mill exit thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com