Method for rolling ultra-thin metal strap

A technology of metal poles and thin strips, applied in the direction of metal rolling, etc., can solve the problems of high cost, low efficiency, difficulty in rolling liquid, powder and granular metal raw materials, etc., to reduce rolling preparation time and shorten rolling Period, the effect of improving the transmission stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

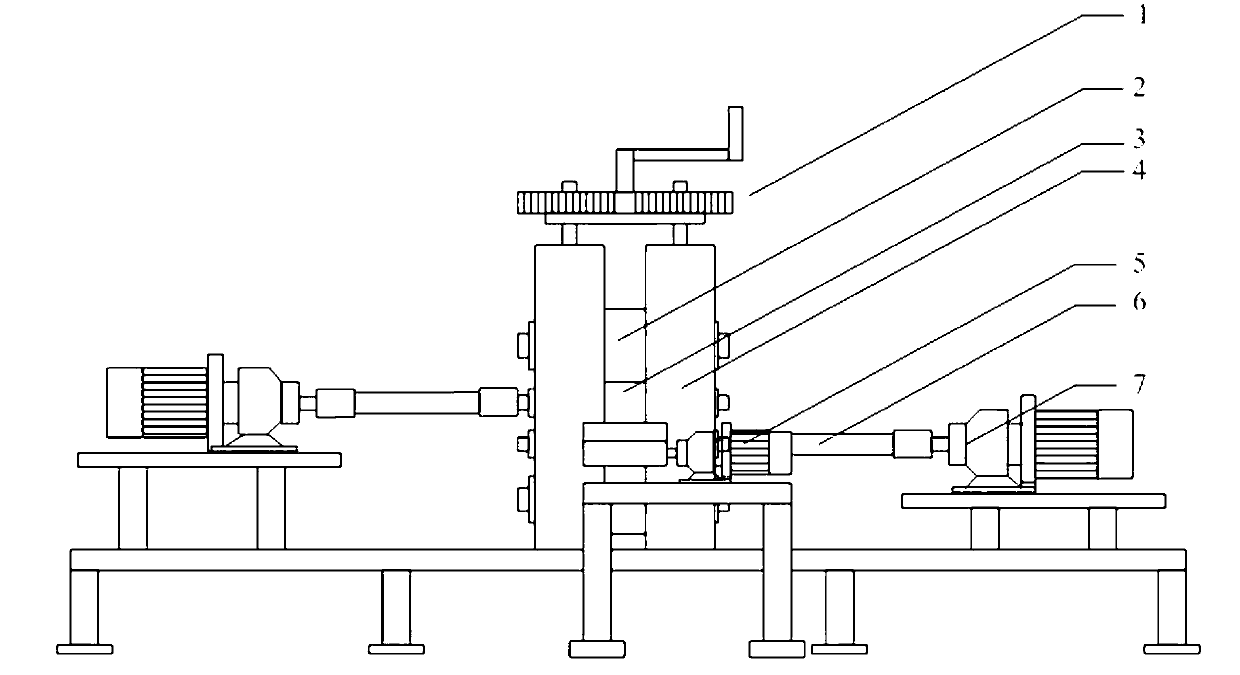

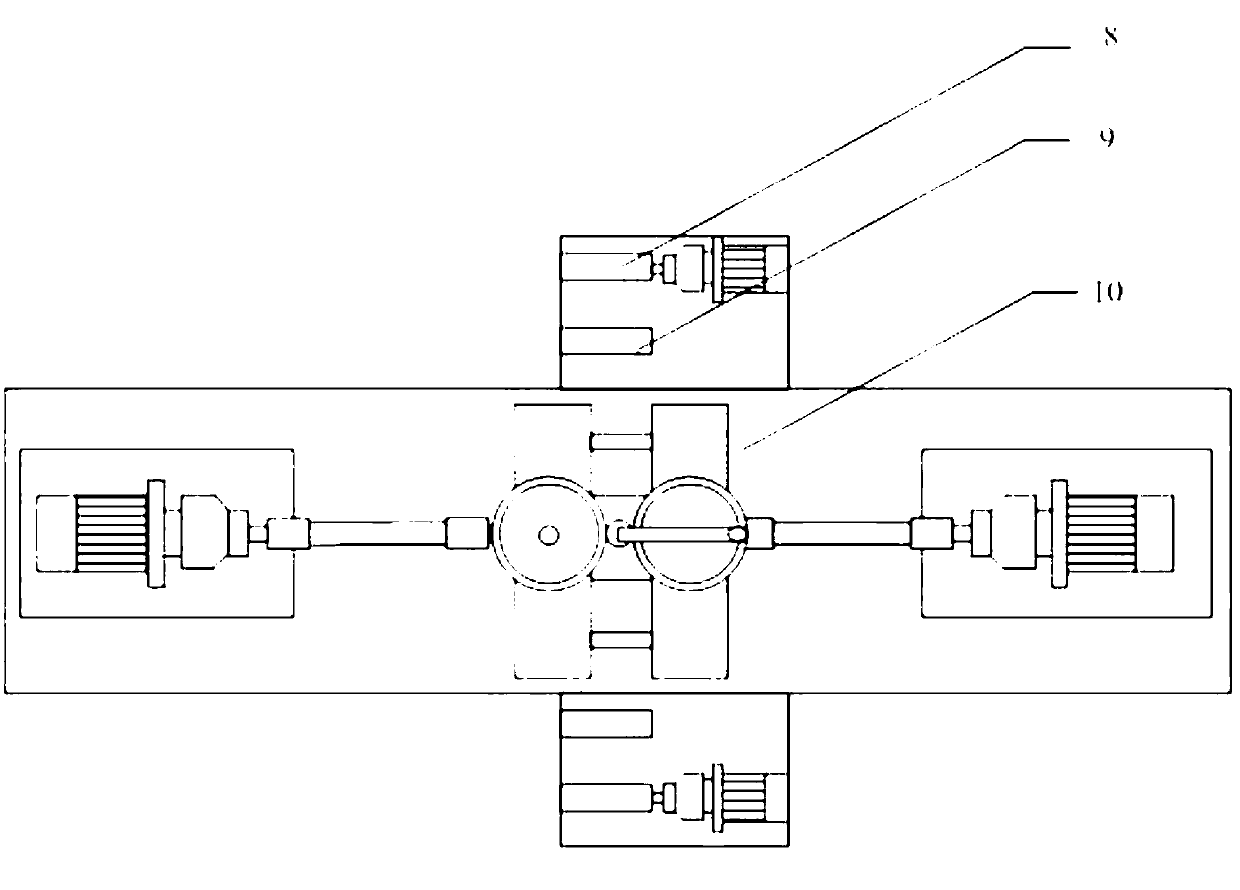

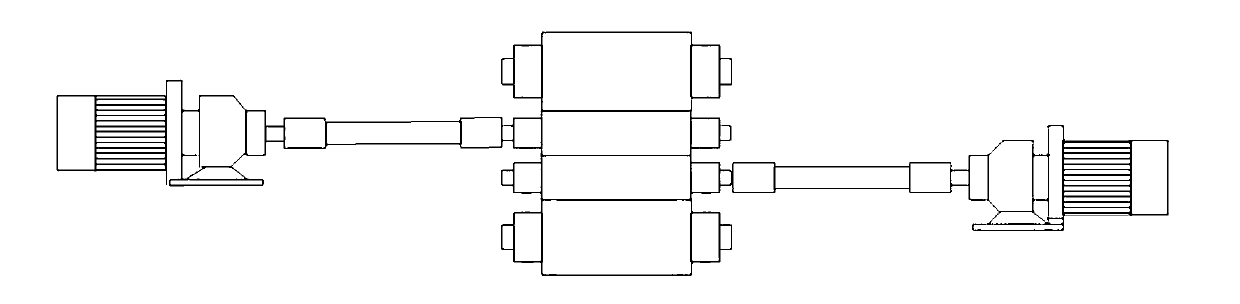

[0034] The aluminum strip with a thickness of 1mm is rolled into an extremely thin strip with a thickness of 4μm, and the operation steps are as follows:

[0035] (1) Start the power supply of the rolling mill system and turn on the main motor fan;

[0036] (2) Shake the handle clockwise to lift the roll gap;

[0037] (3) Wrap the aluminum strip on one side of the reel, and wind the lead-out end on the other reel after passing through the side tension roller, the work roll gap and the two outer side tension rollers, and wind it 3 times;

[0038] (4) Turn on the tension motor to build tension. By adjusting the voltage value of the autotransformer, the front and rear tensions are respectively set to 40MPa, and the yield strength of aluminum is 90MPa;

[0039] (5) Shake the pressing handle counterclockwise to press down the roll gap, the raw material is thicker, and the positive roll gap is selected to be 0.7mm at first;

[0040] (6) Set the speed ratio of the upper and lower ...

Embodiment 2

[0047] The silicon steel strip with a thickness of 0.35mm is rolled into an extremely thin strip with a thickness of 30μm. The operation steps are:

[0048] (1) Start the power supply of the rolling mill system and turn on the main motor fan;

[0049] (2) Shake the handle clockwise to lift the roll gap;

[0050] (3) Wrap the aluminum strip on one side of the reel, and wind the lead-out end on the other reel after passing through the side tension roller, the work roll gap and the two outer side tension rollers, and wind it 2 times;

[0051] (4) Turn on the tension motor to build tension. By adjusting the voltage value of the autotransformer, the tension value is 120MPa, and the yield strength is 280MPa;

[0052] (5) Shake the pressing handle counterclockwise to press down the roll gap, the raw material is thicker, and the positive roll gap is selected to be 0.2mm at first;

[0053] (6) Set the speed ratio of the upper and lower rolls on the man-machine interface, and the spe...

Embodiment 3

[0060] The Q195 steel strip with a thickness of 0.5mm is rolled into an extremely thin strip with a thickness of 25μm. The operation steps are:

[0061] (1) Start the power supply of the rolling mill system and turn on the main motor fan;

[0062] (2) Shake the handle clockwise to lift the roll gap;

[0063] (3) Wrap the aluminum strip on one side of the reel, and wind the lead-out end on the other reel after passing through the side tension roller, the work roll gap and the two outer side tension rollers, and wind it 2 times;

[0064] (4) Turn on the tension motor to build tension. By adjusting the voltage value of the autotransformer, the tension value is 90MPa, and the yield strength is 195MPa;

[0065] (5) Shake the pressing handle counterclockwise to press down the roll gap, the raw material is thicker, and the positive roll gap is selected to be 0.4mm at first;

[0066] (6) Set the speed ratio of the upper and lower rolls on the man-machine interface, and the speed rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com