Control method for improving rolling pace of roughing mill

A technology of rolling rhythm and control method, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of insurmountable and unsuitable rough rolling production line, etc., to shorten the spacing, improve the rolling rhythm and equipment The effect of tight connection between utilization rate and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to better understand the above-mentioned technical solutions of the present invention, the following further describes in detail with reference to the accompanying drawings and embodiments.

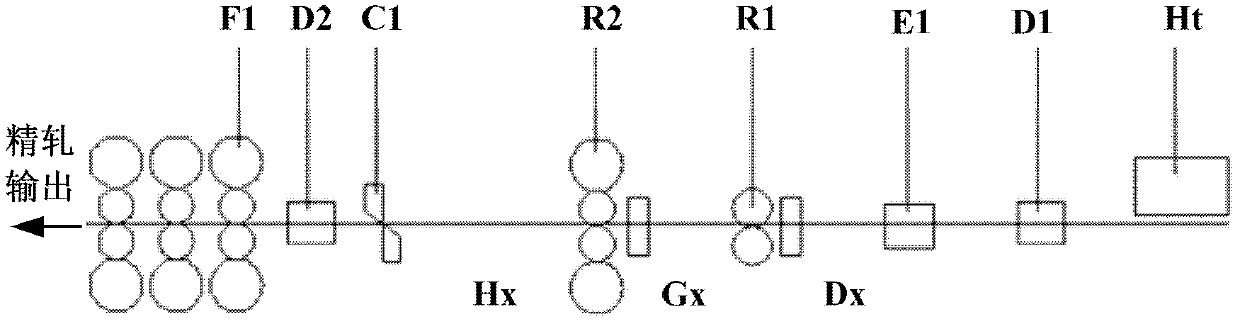

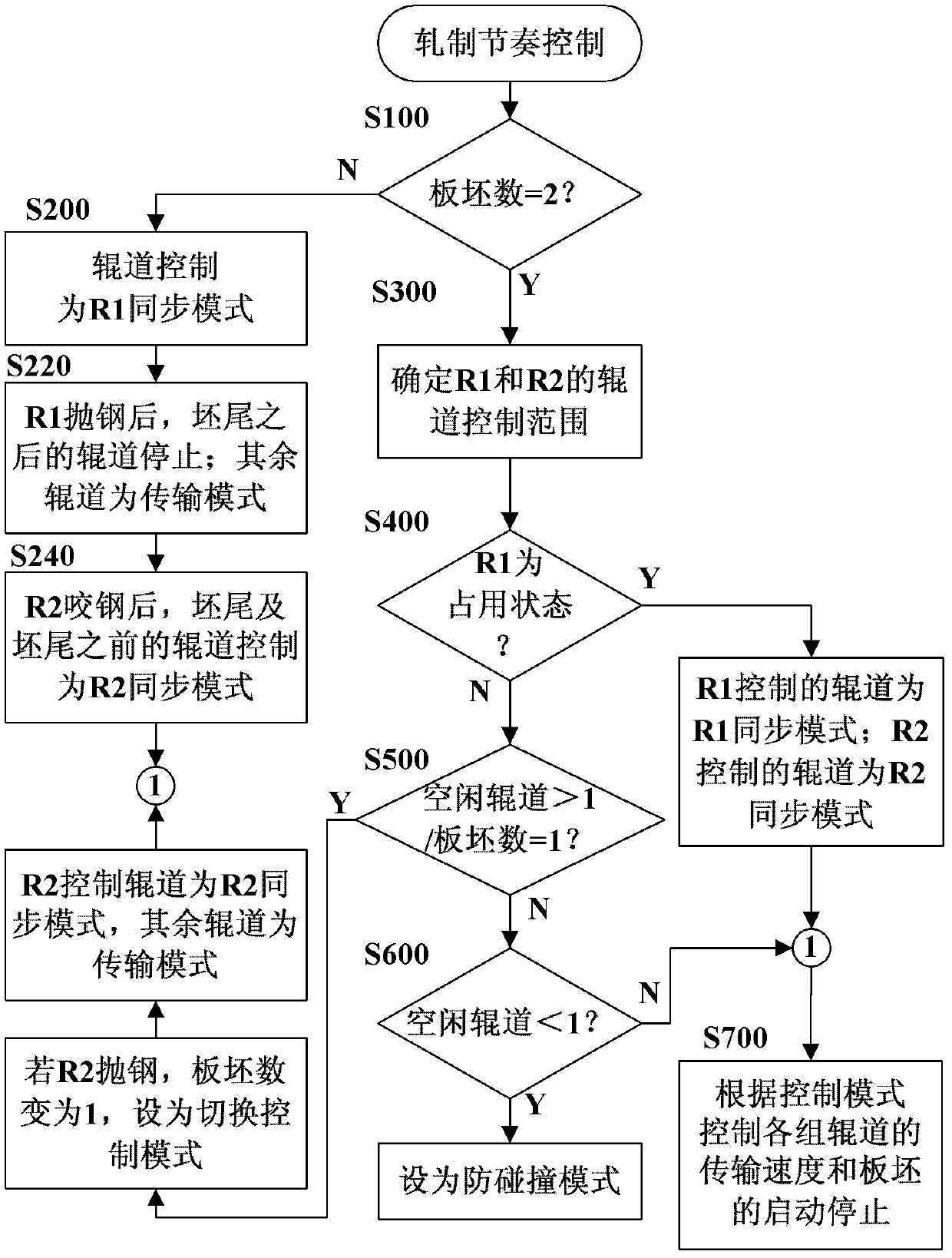

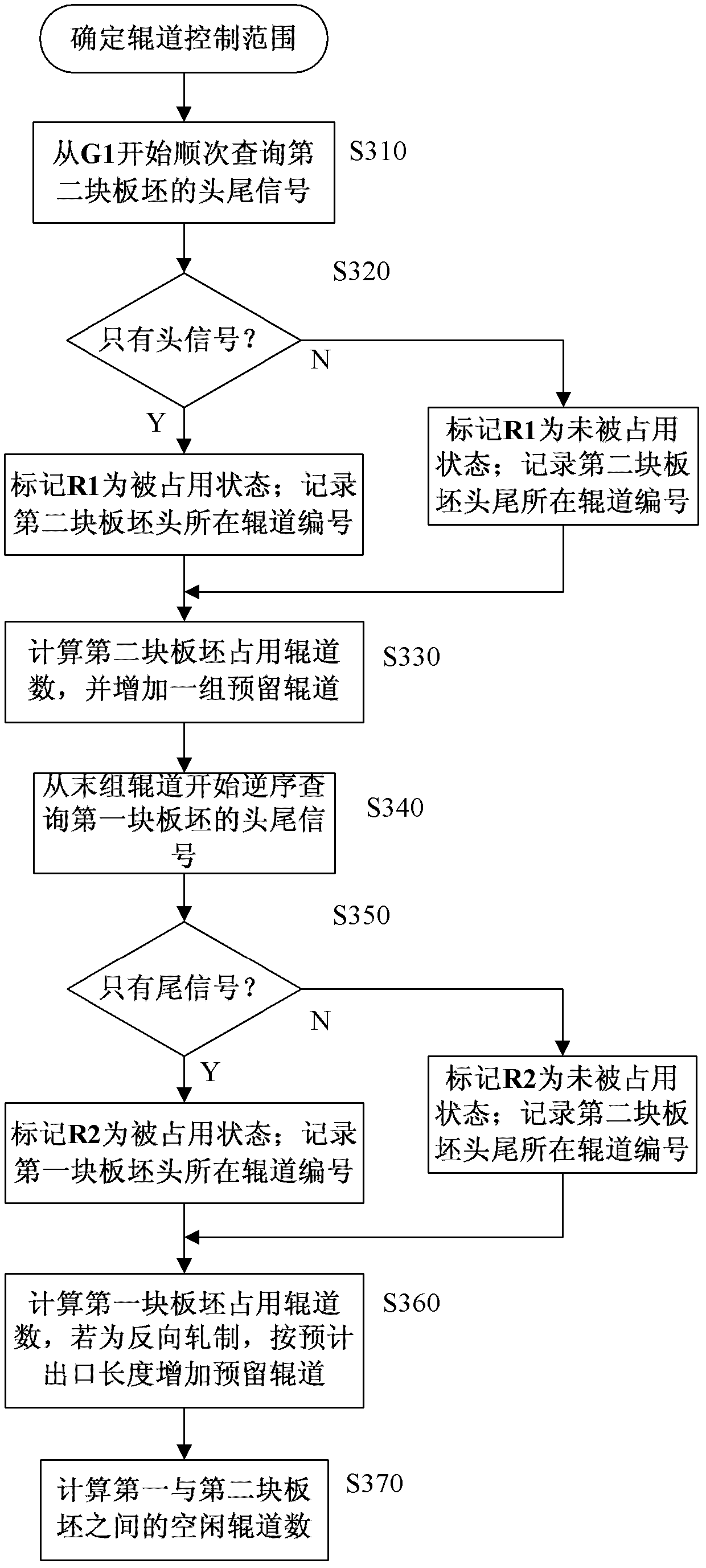

[0062] The control method for improving the rolling rhythm of a rough rolling mill of the present invention is used for figure 1 The control of the rolling rhythm of the roughing mill of the hot rolling production line is shown. The roughing mill includes a first stand R1 and a second stand R2, and several sets of roller tables Gx between the first stand R and the second stand R2, in Figure 4 ~ Figure 9 In the illustrated embodiment, X=1-8, and there are 8 sets of roller conveyors. The processed one or two slabs Bx (x=1 or 2), after rolling at least one pass in the first stand R1, are transferred from the first stand R1 to the first stand R1 through each set of roller tables G1 to G8 Two racks R2, and rolling m passes in the second rack R2 back and forth, where m is an odd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com