Method for controlling steel throwing distance of hot-rolling reversing roughing mill

A control method and rough rolling mill technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems that slabs cannot be rolled normally, the program cannot be reached, and affect the smooth rolling of the rolling mill, so as to avoid The effect of slab failure to normal rolling accidents, improving the rolling rhythm, and avoiding serious fault alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

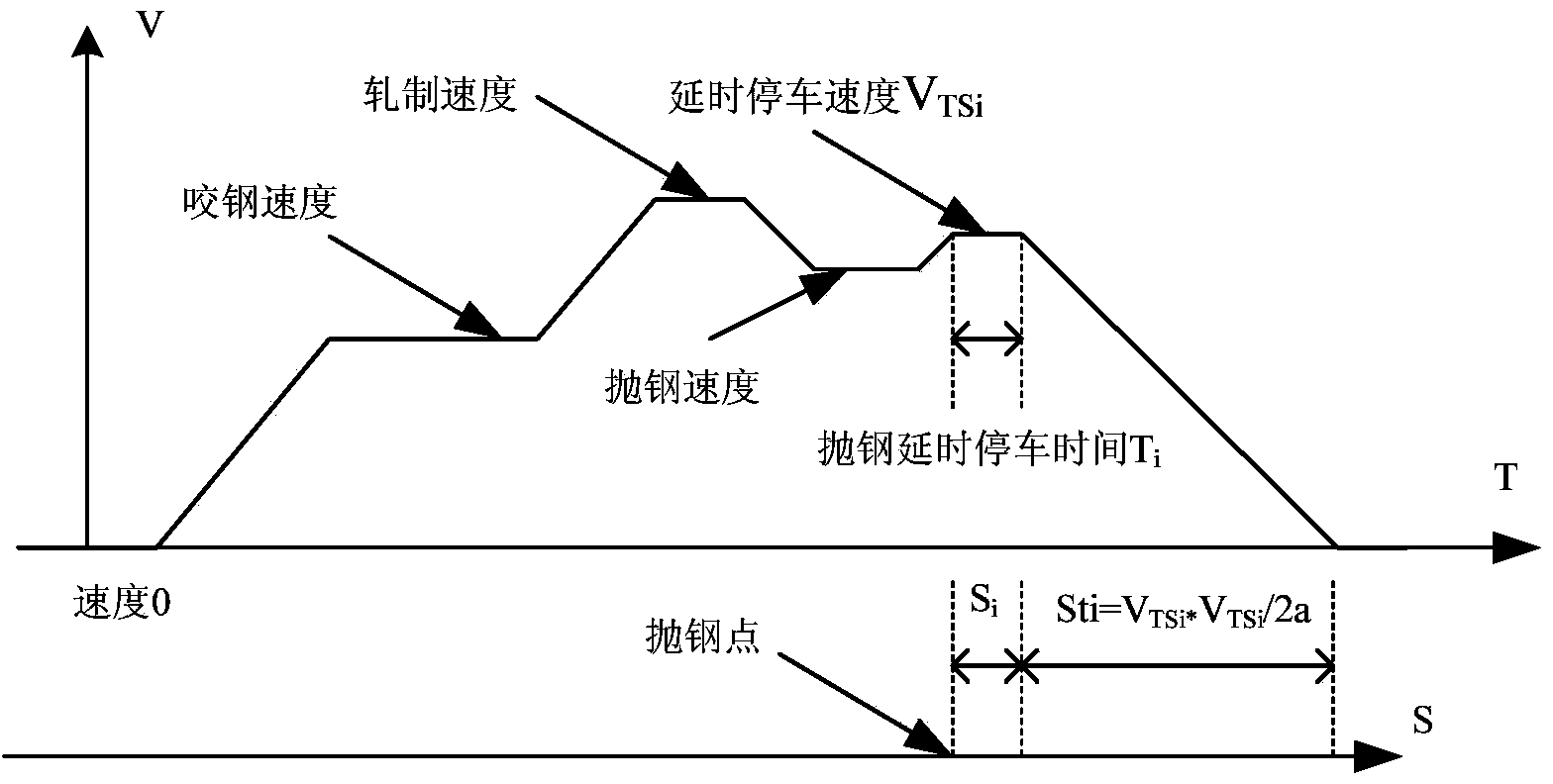

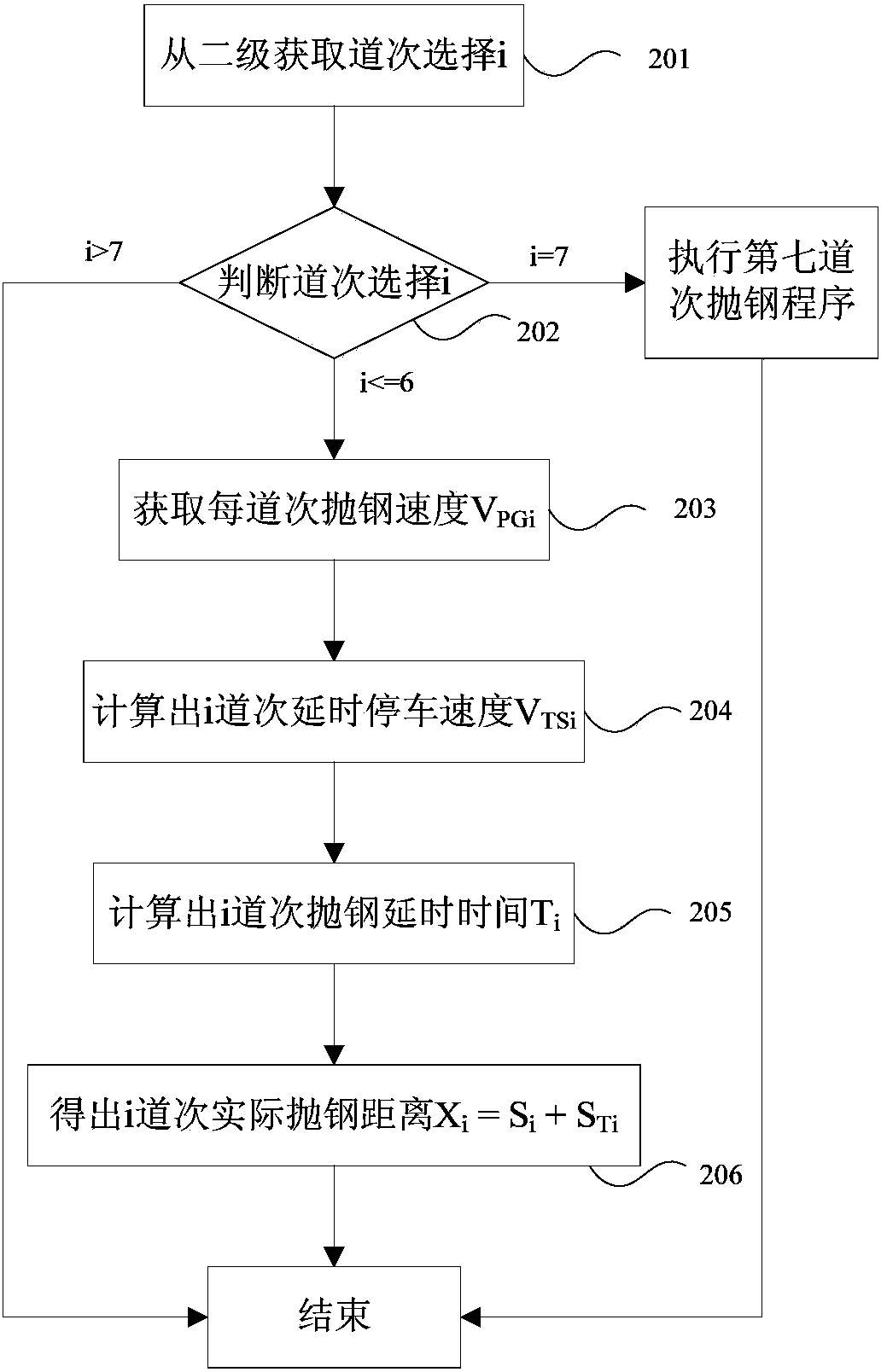

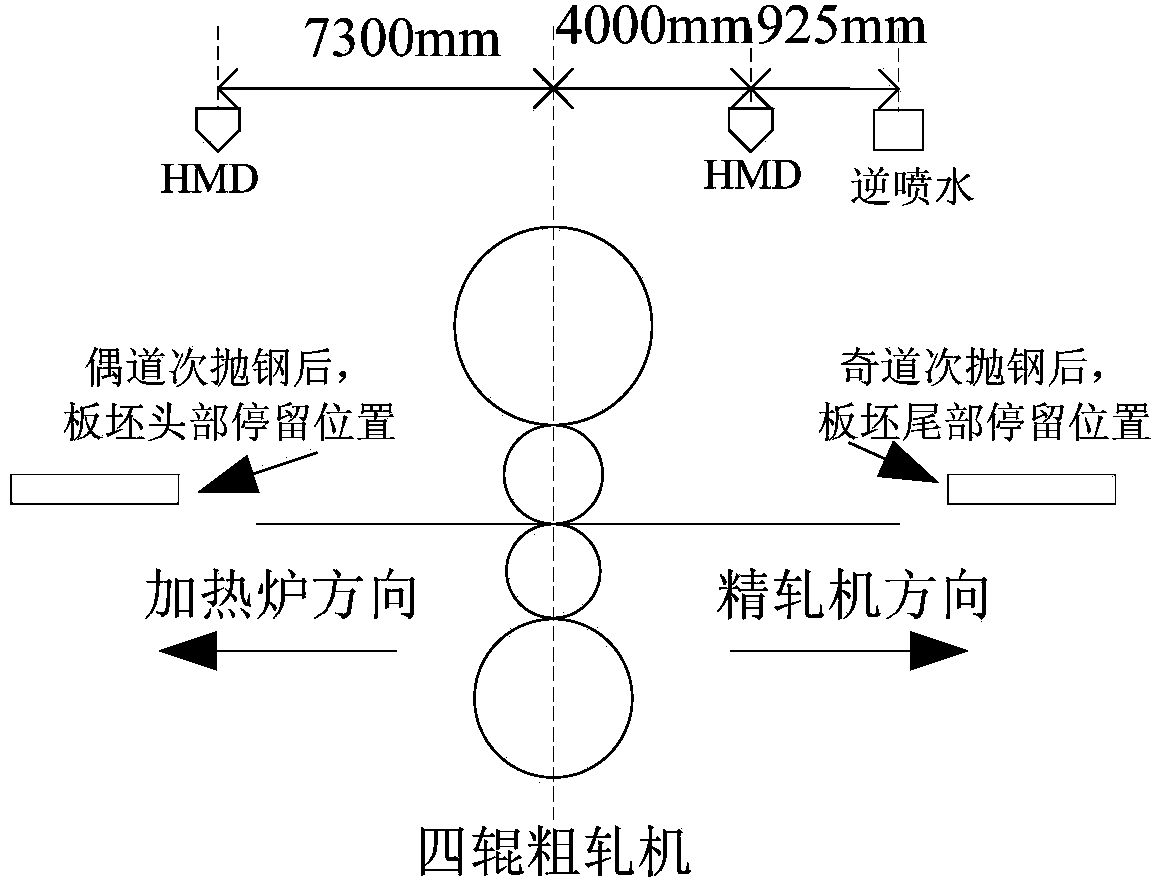

[0017] In the method for controlling the throwing distance of the hot rolling reversible roughing mill provided by the embodiment of the present invention, the delayed stop speed V of each pass is obtained first by calculation. Tsi (Such as figure 1 shown corresponding to the position of the actual steel throwing point of the rolling mill), and then set the steel throwing delay distance constants from the first pass to the sixth pass, which are respectively S 1 , S 2 , S 3 , S 4 , S 5 , S 6 , according to the formula T i =S i / V TSi , calculate the steel throwing delay time from the first pass to the sixth pass as T 1 , T 2 , T 3 , T 4 , T 5 , T 6 , and finally calculate the actual steel throwing distance X from the first pass to the sixth pass 1 、X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com