Large acceleration control method for ensuring finish rolling temperature

A technology of acceleration control and finish rolling temperature, applied in temperature control, roll speed control, metal rolling, etc., can solve the problems of affecting rolling rhythm, increasing plastic deformation heat, unfavorable finish rolling temperature control, etc., to ensure temperature stability performance, improve the effect of rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

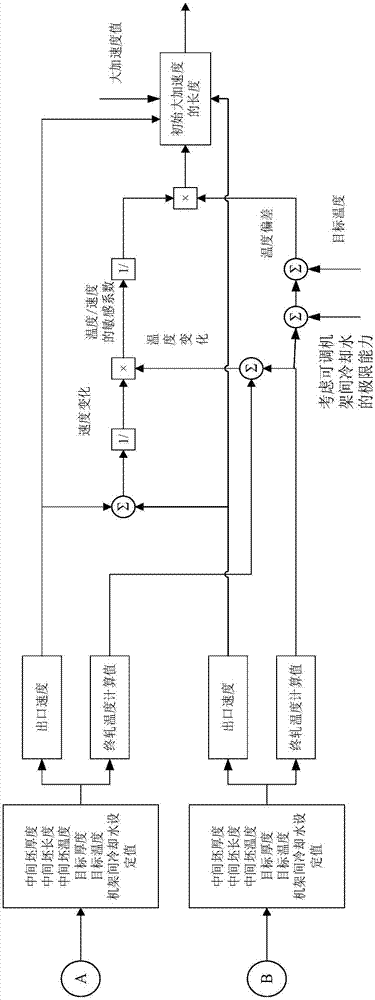

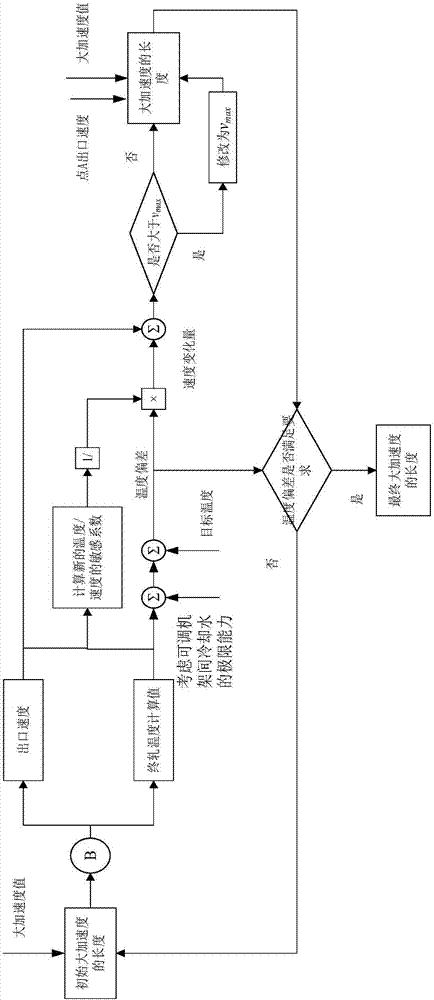

Method used

Image

Examples

Embodiment Construction

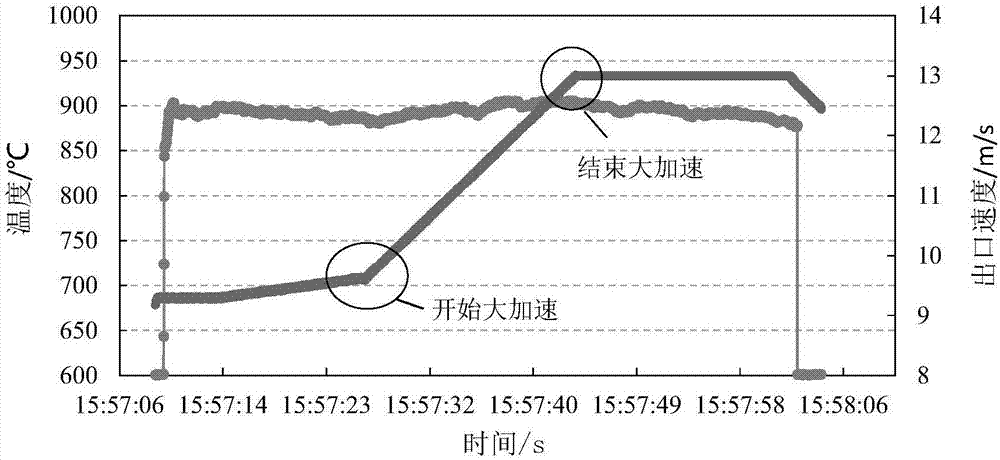

[0033] The embodiment of the present invention provides a large-acceleration control method to ensure the finish rolling temperature, which uses actual process data to calculate the length of the large-acceleration region of the strip, and is applied to the field of temperature control in the rolling process. Select steel type SDC01, specification 3.0*1570mm, take large acceleration as an example, the process parameters are shown in Table 1, and the description is as follows.

[0034] Table 1 Process parameters of each pass of finish rolling

[0035]

[0036] (1) Determine two points in the length direction of the intermediate billet. The determination principle is: when coiling and loading, the position in the length direction of the intermediate billet is point A, which is 9.043m away from the head of the intermediate billet; The position l is determined as point B, and the initial value of l is 3m, which is 12.043m from the head position of the intermediate billet;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com