Model calculation based continuous casting and rolling logistic control method

A technology of model calculation and control method, applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the mismatch between continuous casting rhythm and continuous rolling rhythm, inconsistent logistics and information flow, and low crane operation rate and other issues to achieve the effect of reducing manual workload, speeding up capital turnover rate and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

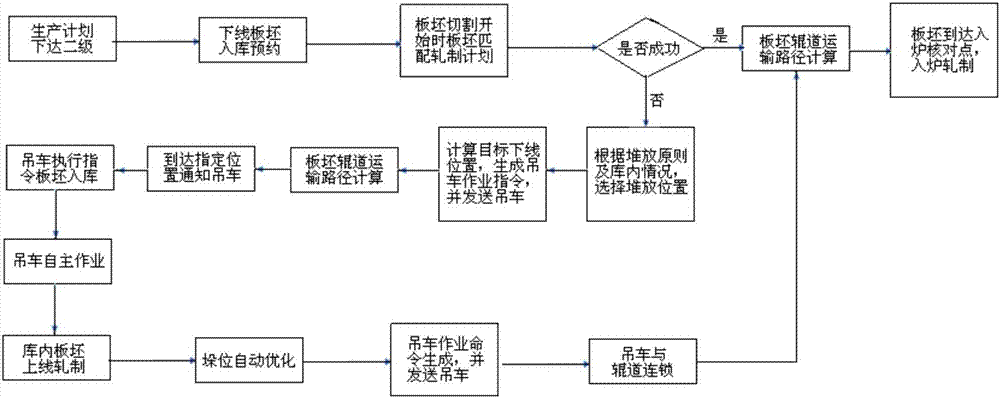

[0027] The continuous casting and rolling logistics control method based on model calculation in the present invention uses a computer management system to perform model calculation, the background operating system is AIX, the background program is developed by C, the database system is oracie, and the model is coded by stored procedures. Its "four streams in one" means that the logistics control process flow of four streams continuous casting into one continuous rolling production line is as follows: figure 1 shown.

[0028] 1. Plan slab warehousing appointment

[0029] After the continuous casting slab plan is issued to the secondary computer, the secondary computer makes a storage reservation according to the off-line sign of the slab in the continuous casting slab plan, and specifies the stacking position of the slab after it goes off the line.

[0030] 2. Slab pre-hanging plan

[0031] When the slab cutting starts, the secondary computer automatically corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com