Crane and synchronous control device and method of double winches

A technology of synchronous control and synchronous control signal, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of detection and calculation errors, complex structure, low control accuracy, etc., and achieve the effect of improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

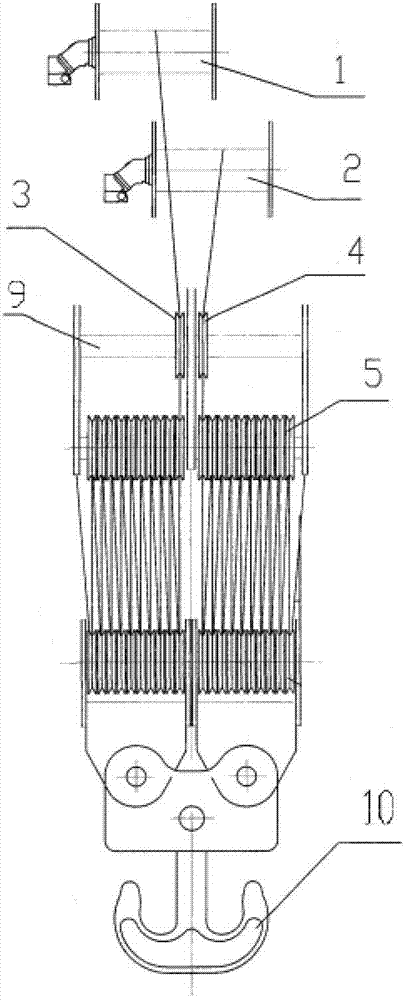

[0041] The core of the invention is to optimize the synchronous control technology of the double winch, and on the basis of reliably controlling the hook assembly to maintain a horizontal posture, it effectively avoids the influence of the unbalanced load on the stability of the whole machine. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0042] Without loss of generality, this embodiment will be described in detail with a wheeled crane as the main body.

[0043] See Figure 4, which is a schematic diagram of the overall structure of the wheeled crane described in this embodiment.

[0044] As shown in the figure, the crane includes a wheeled chassis, a car turntable arranged on the wheel chassis, a boom device hinged at the front of the car turntable, a hoisting device that provides driving force for lifting heavy objects, and a The main functional components such as the counterweight device at the rear of the car t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com