Double-shaft centrifugal fan

A centrifugal fan and rear bearing technology, which is applied in the direction of mechanical equipment, non-variable pumps, non-volume pumps, etc., can solve the problems of transportation and maintenance inconvenience, achieve compact structure, small footprint, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

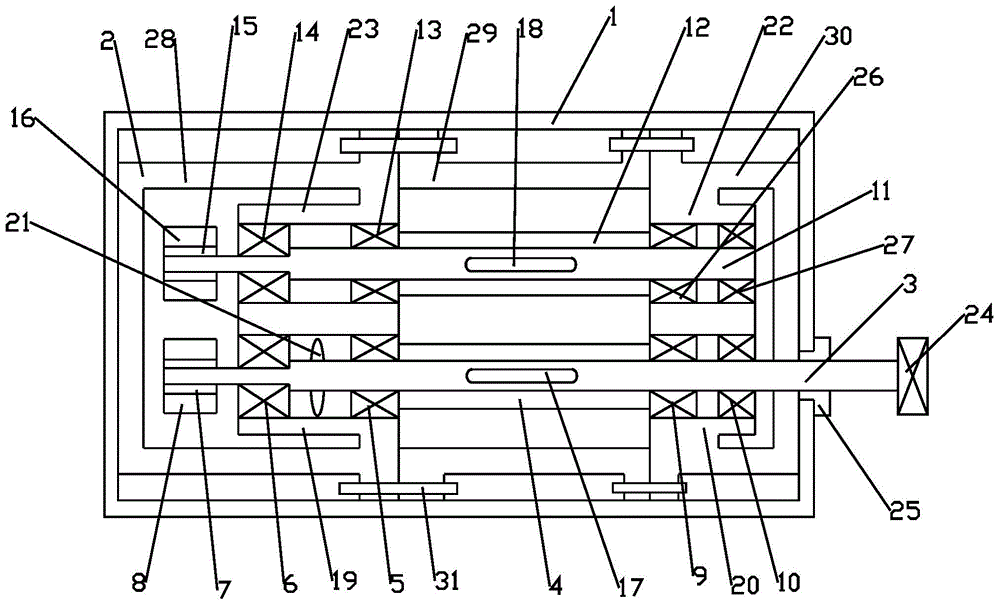

[0018] This embodiment includes a housing 2, the housing 2 is covered with a dustproof box 1, the housing 2 is provided with a driving shaft 3, the driving shaft 3 is covered with a driving impeller 4, and the side of the driving impeller 4 is provided with a first rear seal Ring 5, the first rear bearing 6, the first gear hub 7, the first rear seal ring 5 is located between the driving impeller 4 and the first rear bearing 6, the first rear bearing 6 is located between the first rear seal ring 5 and the first gear Between the hubs 7, the first gear hub 7 is covered with a first gear ring 8, and the other side of the driving impeller 4 is provided with a first front sealing ring 9 and a first front bearing 10, and the first front sealing ring 9 is located on the driving impeller 4 Between the first front bearing 10, the driving shaft 3 passes through the housing 2 and the dustproof box 1, and is connected with a coupling 24. An oil seal 25 is arranged between the driving shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com