Sewing machine edge cutting presser foot

A sewing machine and edge pressing technology, which is applied to sewing machine components, sewing equipment, cloth pressing mechanisms, etc., can solve the problems of trimming offset and affecting the sewing of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

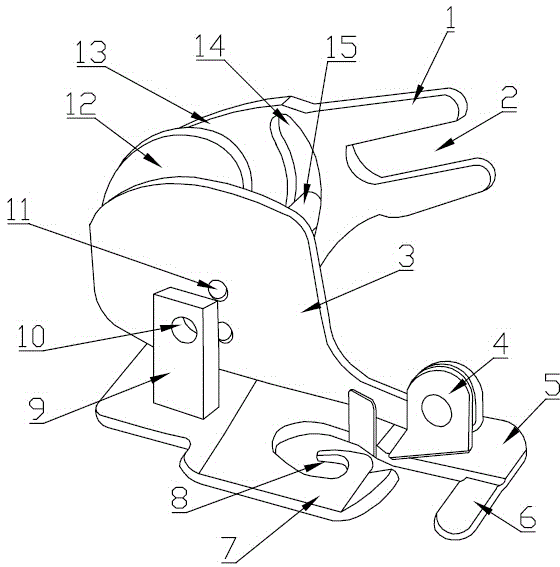

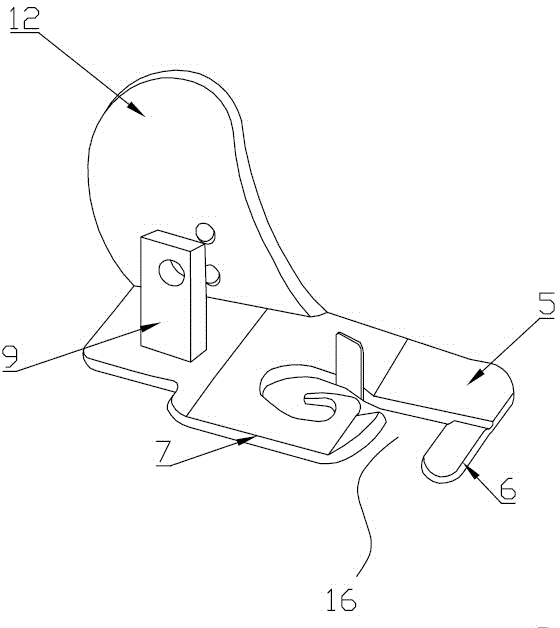

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown is Embodiment 1 of the present invention. The invention comprises a presser foot plate, a cutting knife plate and a swing handle. The presser foot plate includes a presser foot 7 , a guide plate 5 and a support plate 12 . The presser foot 7, the guide plate 5 and the support plate 12 are integrally formed structures. The support plate 12 is perpendicular to the presser foot 7 and the guide plate 5 . One end of the presser foot 7 is bent to form a movable stitch groove 8 , and a lifting plate 6 extends from the side of the guide plate 5 .

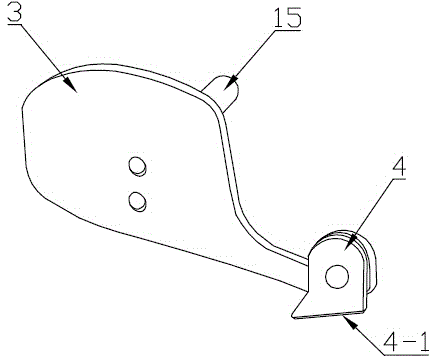

[0015] Cutter plate comprises vertical plate 3, cutter 4 and slide bar 15. Cutter 4 is installed on the riser 3. The vertical plate 3 and the slide bar 15 are also integrally formed structures. Utilize cylindrical pin 11 to fix between vertical plate 3 and su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com