Cascade connected thyristor valve section in jacking connection

A technology of thyristor valves and thyristors, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as poor mechanical stability, deflection, and misalignment of radiators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

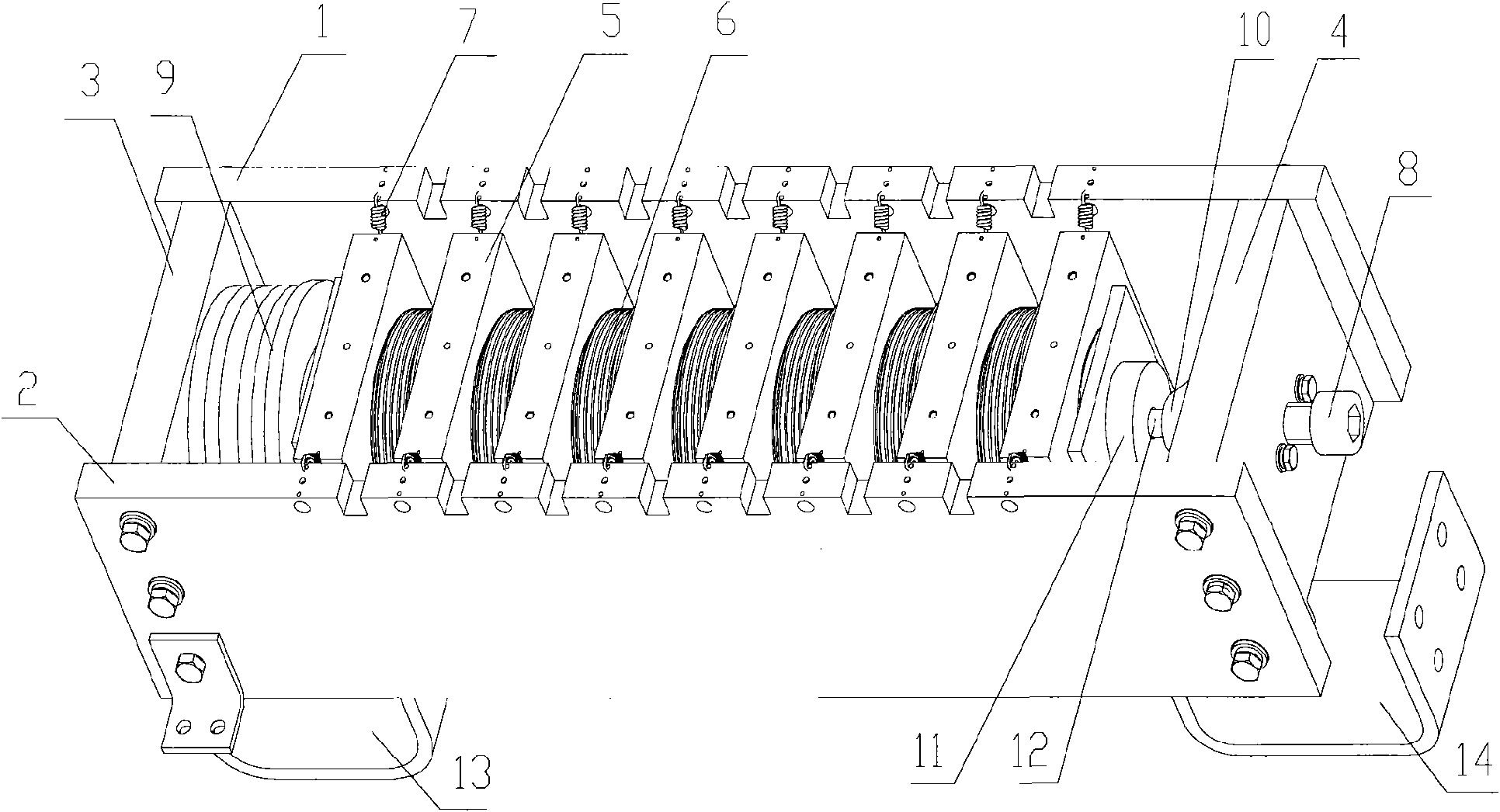

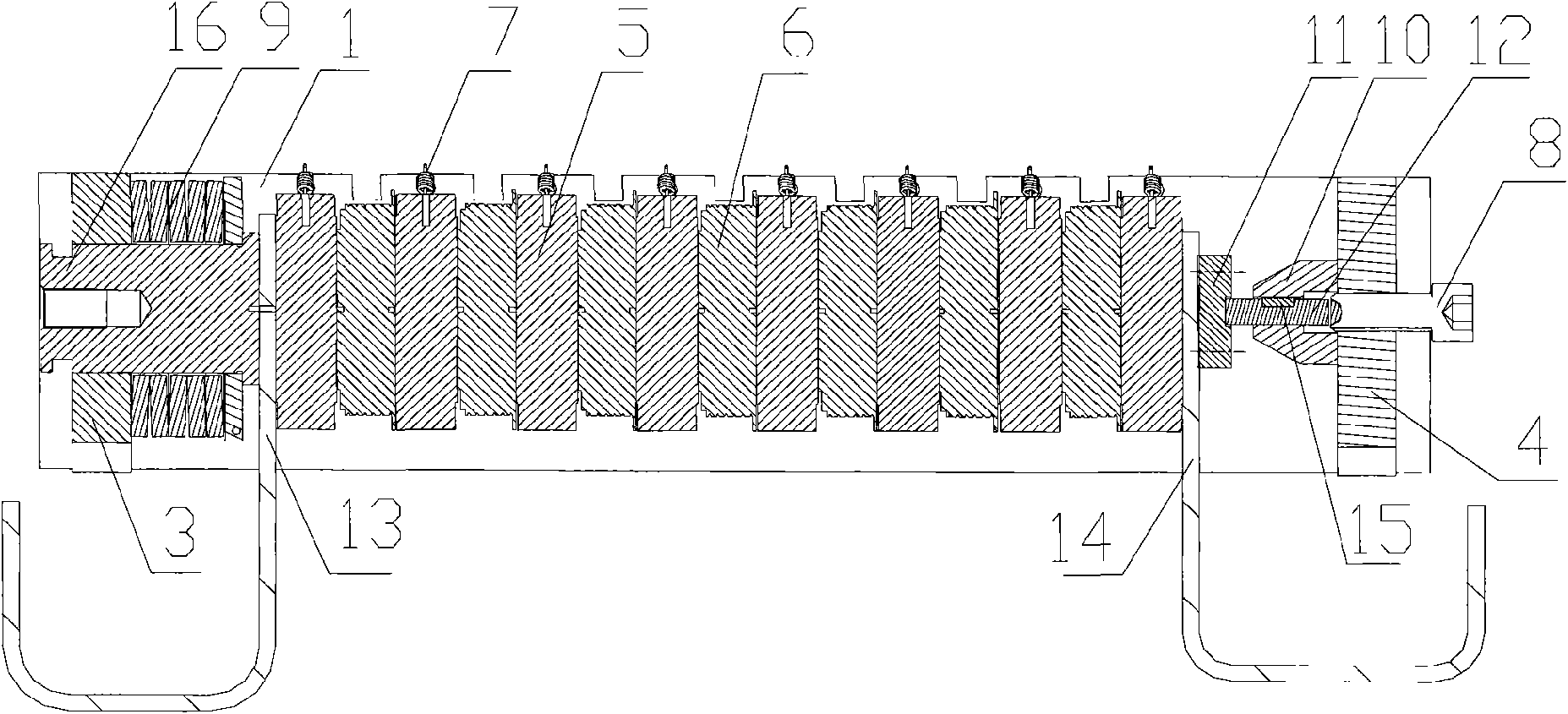

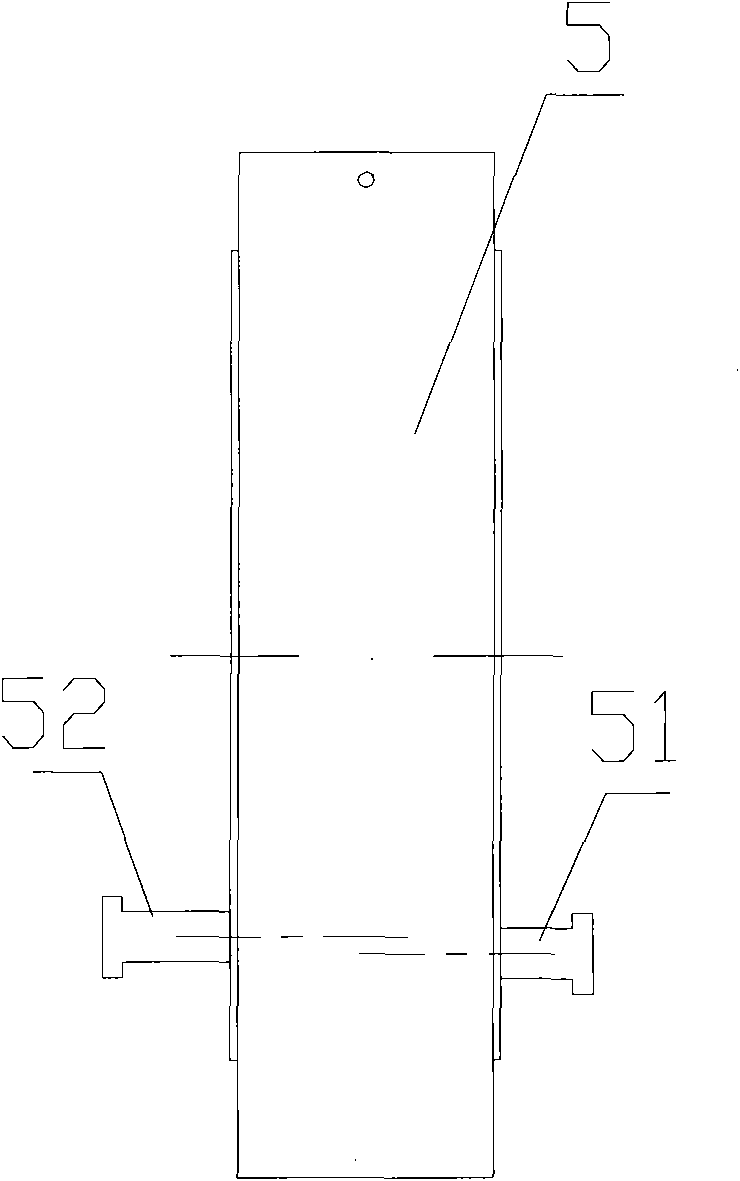

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the series thyristor valve section connected by top pressure of the present invention is a horizontal structure, and the horizontal valve section includes a frame surrounded by fixing plates 1, 2 on both sides and flanges 3, 4 at both ends, and the frame is located at one end The flange 3 is provided with an elastic clamping device composed of a clamping telescopic shaft 16 and a disc spring 9, and the flange 4 at the other end is fixed with a guide sleeve 10, a lock key 15 arranged in the hole of the guide sleeve 10, The pressing device composed of the pressing shaft 12 fitted in the center hole of the guide sleeve 10 and the spherical adjusting bolt 8 screwed on the flange through the lock key 15 axially anti-rotating and slidingly assembled. In order to strengthen the structural stress of the guide sleeve 10, the end of the guide sleeve 10 has a tapered structure. The spherical adjusting bolt 8 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com